Rf 1 2 – Great Plains ADC2350BE Operator Manual User Manual

Page 67

Great Plains Manufacturing, Inc.

Adjustments

63

2012-08-01

167-085M

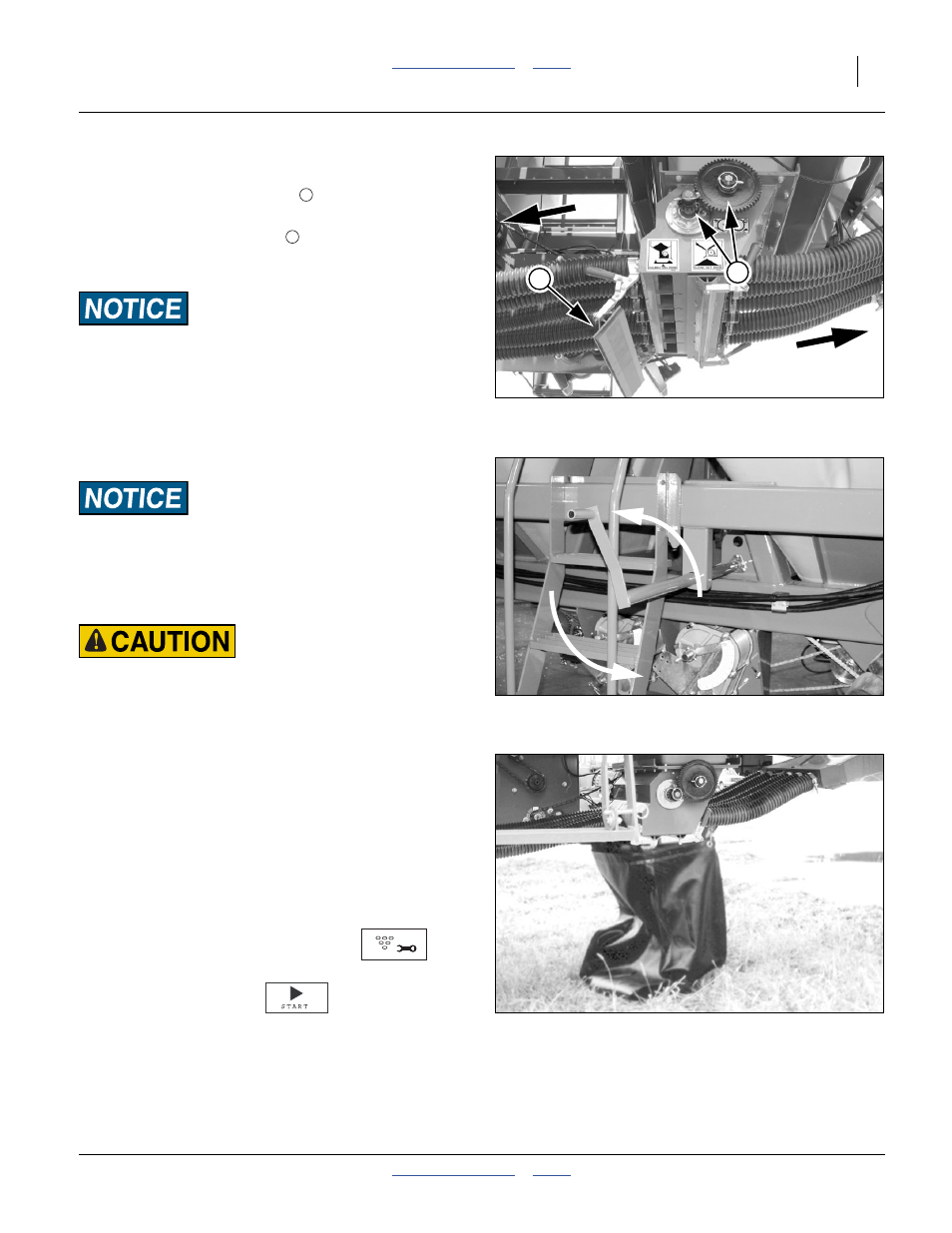

Refer to Figure 72

3.

Since only one calibration bag is provided, remove

one of the final range gears

from the meter that is

NOT being tested, to disable it.

4.

Open the calibration door

of the meter being

calibrated. The calibration door is the rear of the two

bottom doors.

Material Loss Risk: Do not open the front door. This is the

clean-out door. Opening the front bottom door will drain the

hopper. Once the front clean-out door is open it is difficult to

stop seed flow until the hopper is empty.

Refer to Figure 72

5.

Insert calibration crank onto clutch shaft. See “Meter

Hand Crank” on page 36.

Rotate the calibration crank only in the

COUNTERCLOCKWISE direction. Operating in reverse can

cause gearbox damage.

6.

Turn the calibration crank enough turns to be sure

the meter flutes are full and the system is metering.

Obey manufacturer or grower recommendations for safety

equipment and protective gear when using treated seeds.

7.

Wipe all material off the flanges around the meter

door.

8.

Accurately weigh an empty container large enough

to catch material coming out of the meter. The

calibration bag supplied with your cart weighs

3.36 lbs (1.53 kg).

Refer to Figure 73

9.

Place container under open calibration door. If using

the calibration bag, loop bag handles over the door

handles and hook the bag to the front of the meter.

10. On the seed monitor terminal,

set the monitor to Calibration mode

.

enter [ 5 ] for the “# Meter Revs”, and

press the Start softkey

.

This “# Meter Revs” parameter does not affect the

monitor calibration because the monitor counts

actual meter shaft revolutions and uses that count to

compute the Calibration Constant.

The “# Meter Revs” parameter is used for a progress

bar displayed during calibration.

Figure 71

Calibration Door Open

26339

R

F

1

2

1

2

Figure 72

Calibration Crank

26333

Figure 73

Calibration Bag

26402