Cart drive system, Cart sprocket setup – Great Plains ADC2350BE Operator Manual User Manual

Page 23

Great Plains Manufacturing, Inc.

Preparation and Setup

19

2012-08-01

167-085M

Cart Drive System

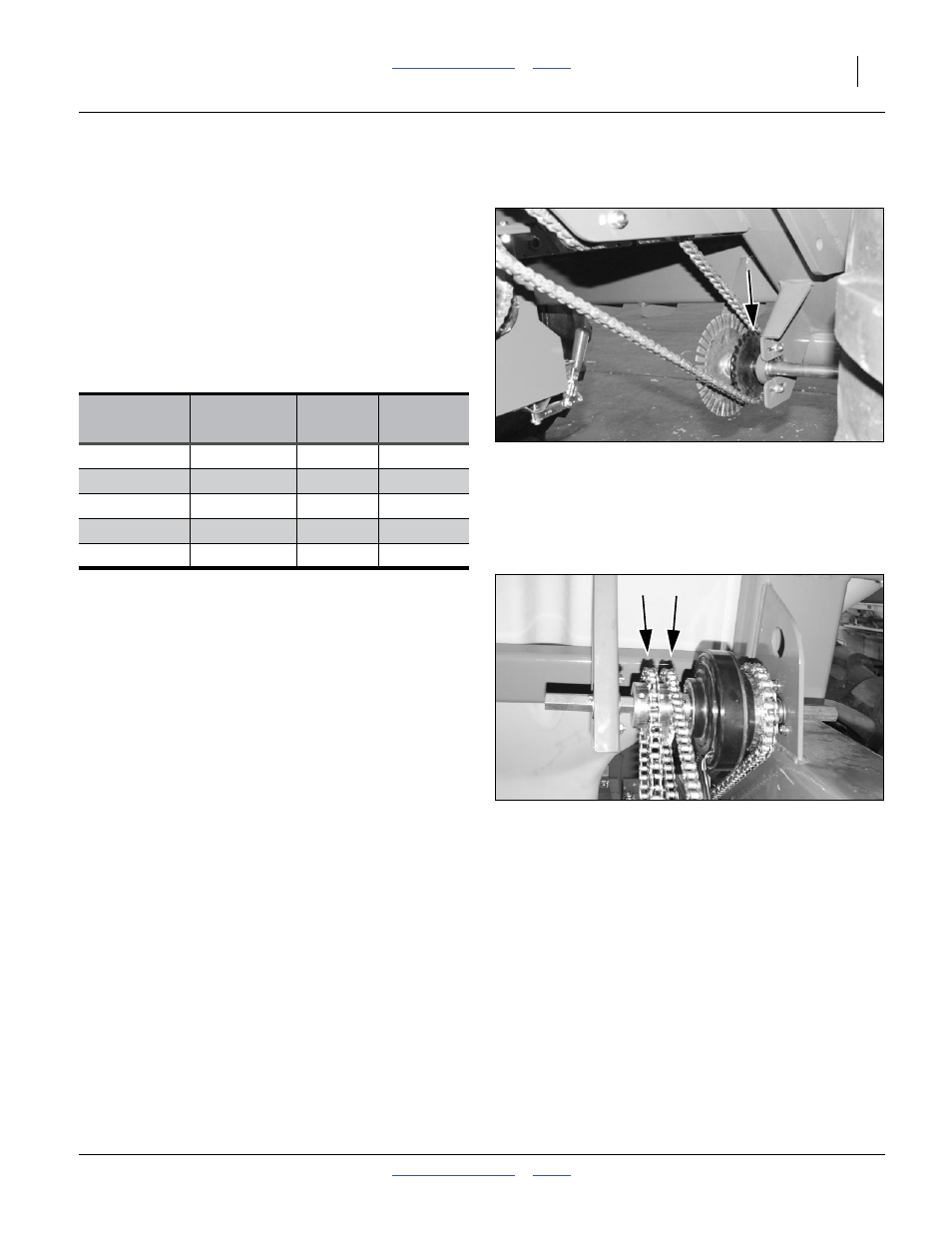

Refer to Figure 7, Figure 8 and table below

Sprockets on the cart need to be checked to ensure that

the seeding rates for your implement match those in the

Seed Rate manual.

The sprockets are factory-installed for a specific

implement, and may be incorrect if the cart is ultimately

delivered with a different implement. Once configured for

a particular implement, cart meter rate is determined by

the variable rate gearboxes and final drive range gears.

Cart Sprocket Setup

Consult the table above. If any sprockets are found to not

match the table, contact your dealer for the correct

replacement sprockets.

Conversion requires one drive shaft output sprocket and

two (2) clutch output sprockets.

Implement

Inner Main

Driveshaft

Clutch

Output

Manifold

Outlets

CTA4000

30T

24T

5 Towers

CTA4000HD

30T

24T

5 Towers

NTA3010

30T

23T

4 Towers

NTA3510

26T

24T

5 Towers

3N-4010HDA

39T

20T

6 Towers

Figure 7

Inner Main Driveshaft Sprocket

26238

Figure 8

Clutch Output Sprockets

26327