Troubleshooting – Great Plains 2S-2600HDF Operator Manual v2 User Manual

Page 79

2014-02-03

195-069M

Great Plains Manufacturing, Inc.

75

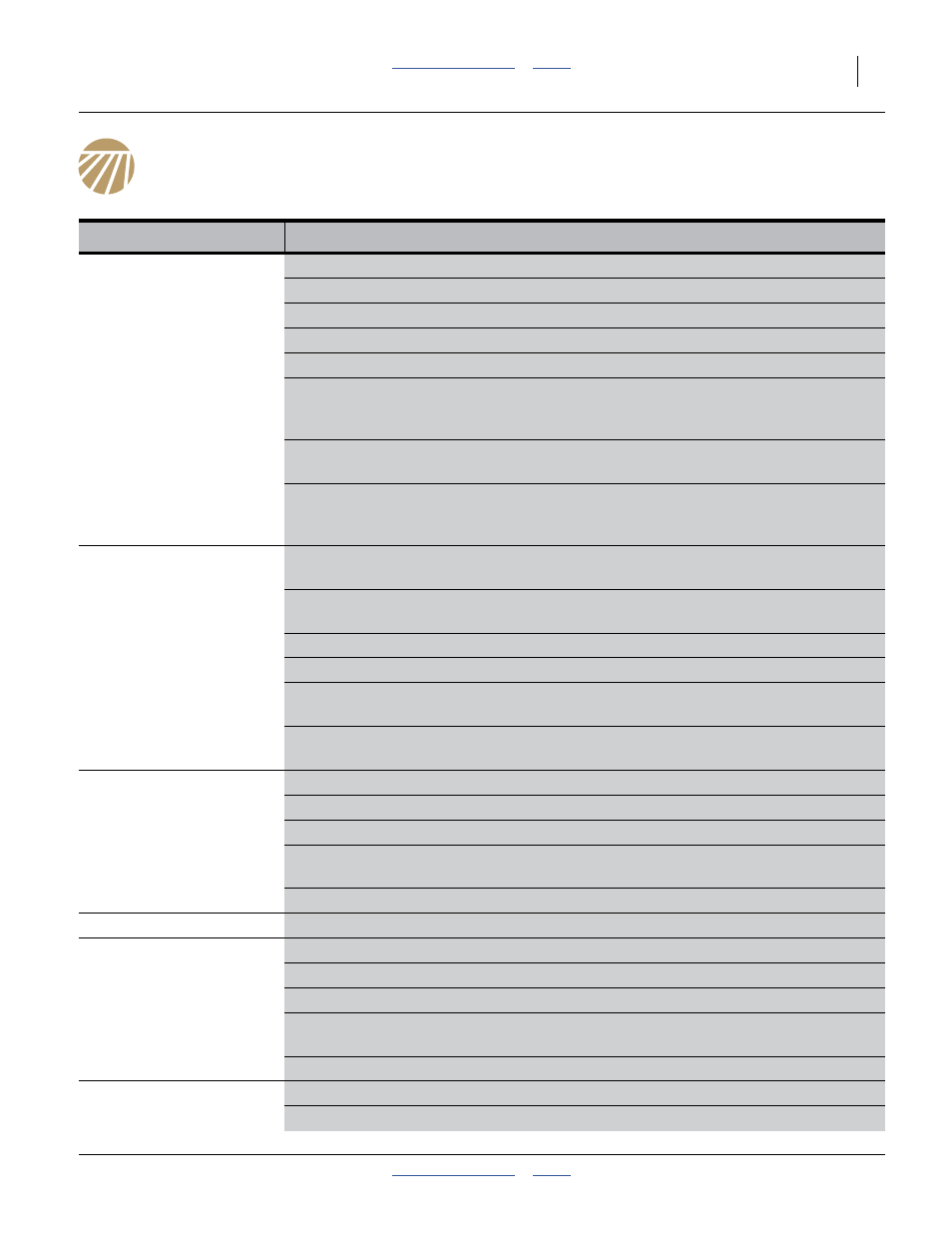

Troubleshooting

Problem

Solution

Uneven seed spacing or

uneven stand

Check for plugging in seed cup.

Check if seed tubes are plugged.

Reduce ground speed.

Check that opener disks turn freely.

Use a faster drive type and close seed-cup doors to narrower position.

Check if openers have enough down pressure to penetrate soil. Increase hydraulic

down pressure on openers if necessary. See “Setting Hydraulic Down-Pressure” on

page 63.

Check for trash or mud build-up on Seed-Lok wheels. Lock up if necessary. See

“Seed-Lok™ Seed Firmer Lock-Up” on page 69.

Check if hydraulic down pressure on openers is too high, causing gauge wheels to

loose contact with ground. Decrease hydraulic down pressure if necessary. See “Set-

ting Hydraulic Down-Pressure” on page 63.

Opener disks not turning

freely

Check for trash or mud build-up on disk scrapers. Readjust scrapers if necessary. See

“Disk Scraper Adjustments” on page 68.

Check if scrapers are adjusted too tight, restricting disk movement. Readjust scrapers

if necessary. See “Disk Scraper Adjustments” on page 68.

Check disk bearings.

Check opener frame for possible damage.

If opener disks turn freely by hand but not in field, reduce hydraulic down pressure.

See “Setting Hydraulic Down-Pressure” on page 63.

Check press-wheel adjustment for seeding depth. See “Setting Hydraulic

Down-Pressure” on page 63.

Actual seeding rate

is different than desired

Check tire pressure. See “Tire Inflation Chart” on page 104.

Check wing gauge wheels. Proper size is 9.5Lx15 6-ply Rib Implement.

Check for build-up of seed treatment. Regularly clean off build-up.

Check seed-rate setting. See “Main Box Seed Rate Calibration” on page 50 or

“Small Seeds Rate Calibration” on page 58.

Consider your seed weight. Seed-rate charts are based on average seed weights.

Excessive seed cracking

Use slower drive type and open seed-cup doors to a wider position.

Acremeter doesn’t mea-

sure accurately

Check tire pressure. See “Tire Inflation Chart” on page 104.

Check gauge-wheel tires. Proper size is 9.5Lx15 6-ply Rib Implement.

Check planting operation for excessive overlap or gaps between passes.

Consider soil conditions. Loose soil and slippage will cause variations in acres regis-

tered.

Check that your acremeter is for your drill. Refer to the 2S-2600 parts manual.

Uneven seeding depth

See “Opener Depth (Press Wheel Height)” on page 69.

Check that drill tongue matches tractor-drawbar height. See “Hitching” on page 14.