Opener-subframe adjustment – Great Plains 2S-2600HDF Operator Manual v2 User Manual

Page 68

64

2S-2600HD

Great Plains Manufacturing, Inc.

195-069M

2014-02-03

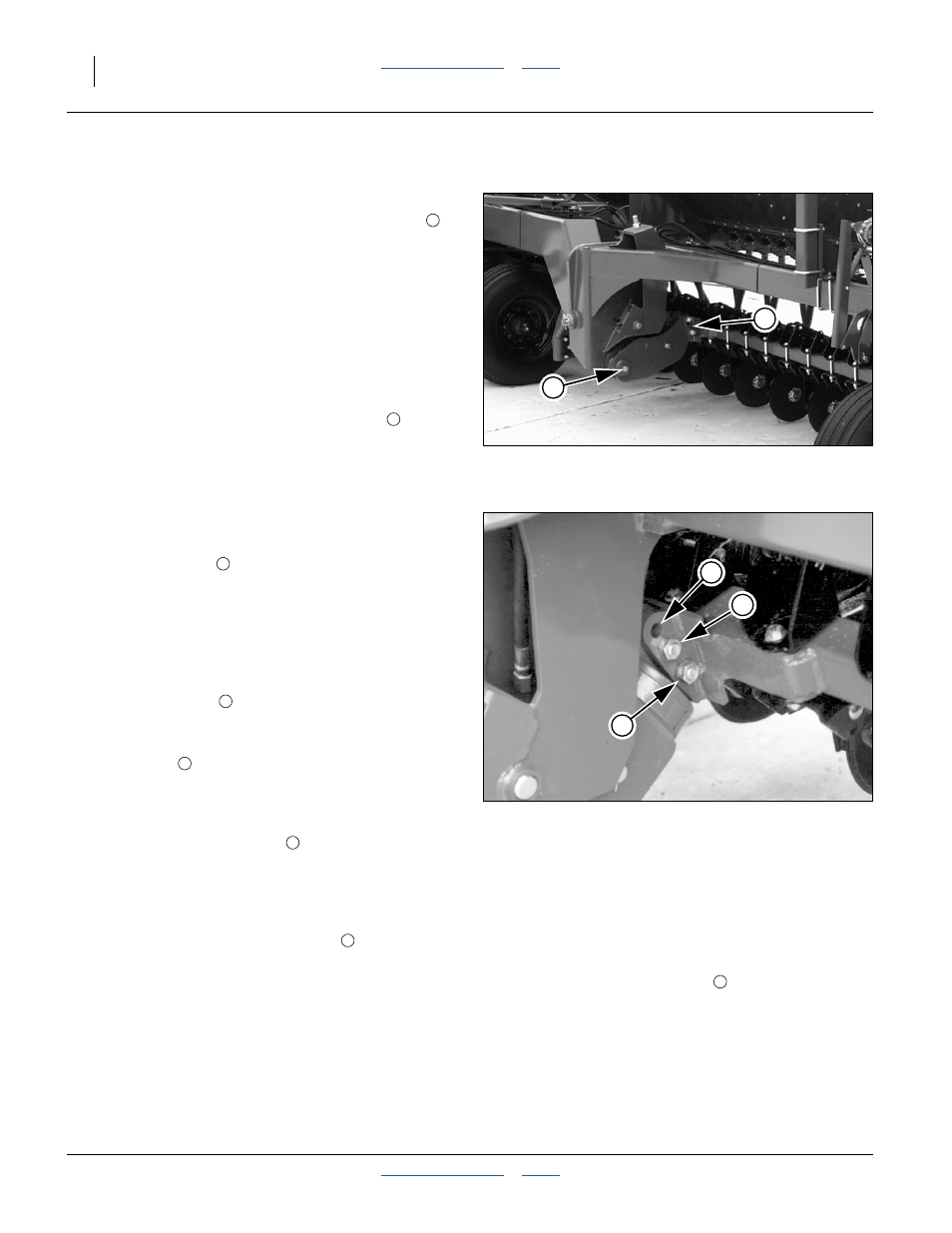

Opener-Subframe Adjustment

Refer to Figure 60

Each drill section has an opener frame which pivots

about the centerline of the drill gauge wheels. These

floating opener frames have the ability to rock the open-

ers 15 degrees up and 15 degrees down as a group. By

pivoting at the gauge wheels, openers maintain a consis-

tent depth as opener frames rock up and back.

Down pressure for each opener frame is provided by two

cylinders working on a constant lever arm. When com-

bined with live hydraulics, the cylinders provide constant

down pressure across the width of each opener frame –

regardless of how the frame is positioned. Two cylinders

per opener frame along with special trunnions

also

provide some ability for one end of an opener frame to

rock independent of the other while maintaining constant

opener down pressure across the frame.

At higher down-pressures (above 2100 psi), the row units

can tend to tip forward. An adjustment to the main-

frame/subframe pivot corrects this.The opener frame has

one adjustment point

for two different operating posi-

tions.

Refer to Figure 61 (shown in factory default configuration)

You can adjust opener frames between two operating

positions–one for normal down pressure and one for

higher down pressure. The adjustment is near the

opener frame pivots. There are three holes and two

bolts. The bottom bolt

serves as the pivot. The top bolt

is for adjustment.

• For normal drilling conditions, keep top bolt in second

(middle) hole

at all six frame pivots. Use this setting

when drilling with opener down pressure below 2100

psi.

• When drilling with opener down pressure above 2100

psi, place top bolt in top hole

on all six pivot points

across drill.

To change the bolts (to high pressure):

1.

Have a jack at hand.

2.

Loosen the nuts on all the top bolts

.

3.

Lower the opener sub-frames.

4.

Put the tractor hydraulic circuit for the openers in

float.

5.

Place jack under an opener tool bar at an arm.

6.

Lift the tool bar until the bolt is free.

7.

Remove the bolt.

8.

Repeat step 5 through step 7 the other arm of the

subframe.

9.

Raise the jack until the top holes are aligned.

10. Insert the bolt in the top hole

and spin on a nut.

11. Repeat step 5 through step 10 for each sub-frame.

12. Tighten all nuts.

Changing from high to low is similar, except lower the

jack at step 6 and reverse the bolt movement.

Figure 60

Opener-Frame Pivot

18857

1

2

1

2

Figure 61

Opener-Frame Adjustment

15558

3

4

5

2

3

4

5

4

5