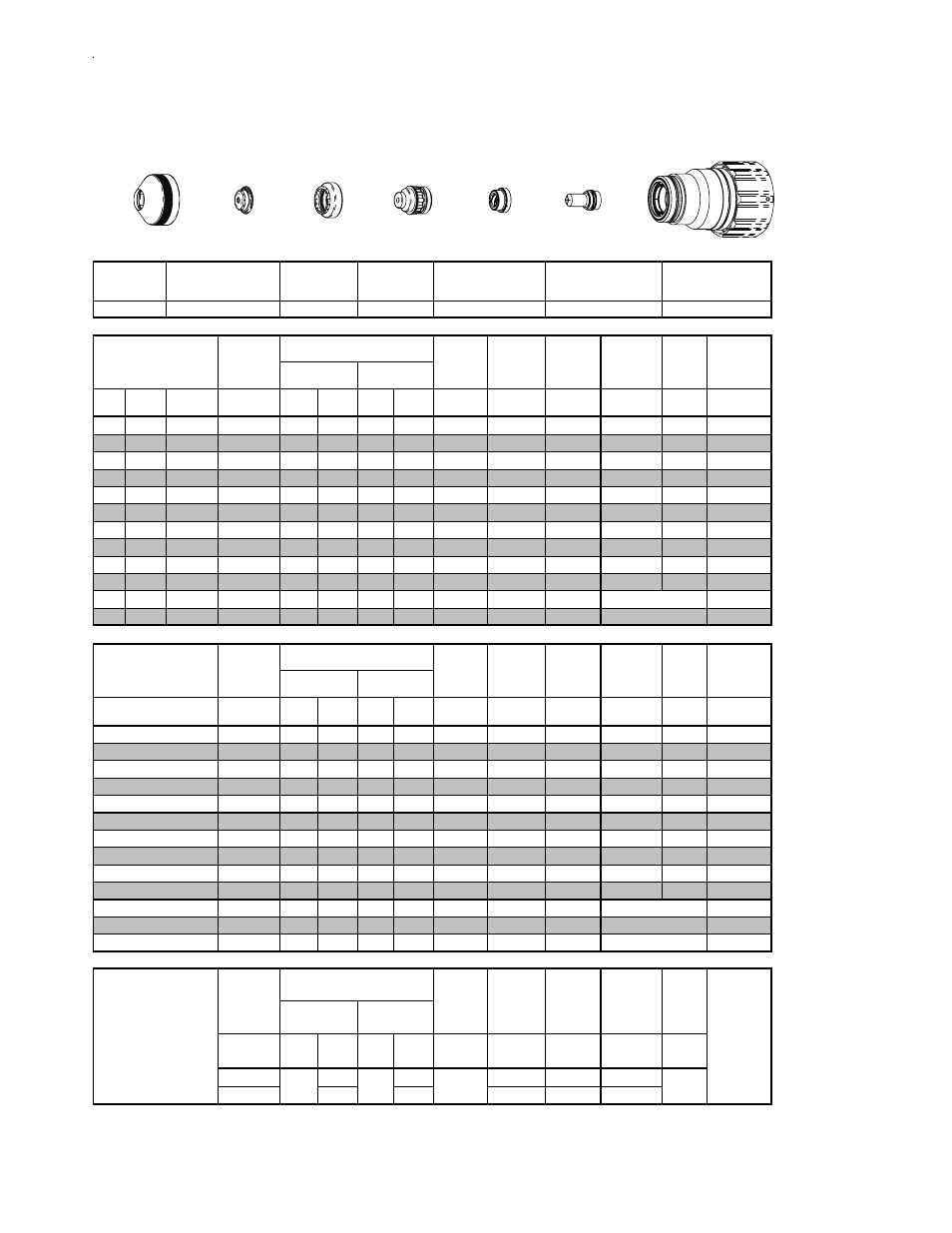

Mild steel 200a o, Plasma / air shield, This art is for reference only – Tweco XT-300 Torch for OEM UC-300 User Manual

Page 44

TORCH DATA for Ultra-Cut

8-46

Manual 0-4829 Rev AN

(ga)

(in)

inch

(PSI)

(Ball)

(PSI)

(Ball)

(PSI)

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

3/16

0.188

15

100

100

NA

100

151

0.130

250

0.300

0.2

0.142

1/4

0.250

15

100

100

NA

100

151

0.130

200

0.300

0.2

0.148

3/8

0.375

15

100

100

NA

100

154

0.150

140

0.350

0.3

0.162

1/2

0.500

15

100

100

NA

100

159

0.170

115

0.350

0.5

0.167

5/8

0.625

15

100

100

NA

100

161

0.200

80

0.350

0.6

0.186

3/4

0.750

15

100

100

NA

100

163

0.200

65

0.400

0.8

0.186

7/8

0.875

15

100

100

NA

100

166

0.200

57

0.400

1.0

0.185

1

1.000

15

100

100

NA

100

167

0.200

48

0.400

1.2

0.193

1 1/4

1.250

15

100

100

NA

100

170

0.200

30

0.425

2.0

0.196

1 1/2

1.500

15

100

100

NA

100

185

0.200

20

0.450

4.0

0.201

2

2.000

15

100

100

NA

100

192

0.200

10

0.204

2 1/2

2.500

15

100

100

NA

100

192

0.200

8

0.210

(Bar)

(Ball)

(Bar) (Ball)

(Bar)

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

1.0

100

6.9

NA

6.9

151

3.3

6170

7.6

0.2

3.6

1.0

100

6.9

NA

6.9

151

3.3

5360

7.6

0.2

3.7

1.0

100

6.9

NA

6.9

153

3.6

4290

8.3

0.3

3.9

1.0

100

6.9

NA

6.9

155

3.9

3460

8.9

0.3

4.1

1.0

100

6.9

NA

6.9

158

4.2

3060

8.9

0.5

4.2

1.0

100

6.9

NA

6.9

160

4.0

2280

8.9

0.6

4.6

1.0

100

6.9

NA

6.9

164

5.1

1590

10.2

0.9

4.7

1.0

100

6.9

NA

6.9

167

5.1

1250

10.2

1.2

4.9

1.0

100

6.9

NA

6.9

171

5.1

750

10.8

2.1

5.0

1.0

100

6.9

NA

6.9

185

5.1

510

11.4

4.0

5.1

1.0

100

6.9

NA

6.9

188

5.1

390

5.1

1.0

100

6.9

NA

6.9

192

5.1

270

5.2

1.0

100

6.9

NA

6.9

192

5.1

200

5.3

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

Volts

in ±0.005 /

mm ±0.1

ipm /

mm/min

in ±0.005 /

mm ±0.1

(sec)

15

60

80

0.120

300

0.120

1.0

4.1

5.5

3.0

7600

3.0

Mild Steel

200A

O

2

Plasma / Air Shield

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later

22-1022

22-1014

22-1030

22-1285

22-1055

Material

Thickness

Pre Flow

Pressure

(Air)

NOTE: Lock pierce height betw een 0.5" to 1" to avoid torch hitting the pierce metal puddle.

Shield

Retainer

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Electrode

Cartridge

22-1042

22-1093

Cut Flow Rates / Pressures

Arc

Voltage

Kerf Width

@ Rec.

Speed

Plasma (O

2

) Shield

(Air)

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Edge Start

Material

Thickness

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Edge Start

Kerf Width

@ Rec.

Speed

Plasma (O

2

) Shield

(Air)

(mm)

5

6

8

10

25

32

12

15

20

Travel

Speed

Initial

Transfer

Height

Pierce

Delay

38

44

Edge Start

50

Edge Start

60

Edge Start

80

NA

168

Torch

Working

Height

0

Marking

25A Arc Current

Pre Flow

Pressure

(N

2

)

Cut Flow Rates / Pressures

Arc

Voltage

Marking

quality

degrades

as

thickness

decreases

Plasma (N

2

) Shield

(N

2

)

Cartridge

Electrode

Shield

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Shield Retainer

Art # A-07917_AC

This Art Is For Reference ONLY