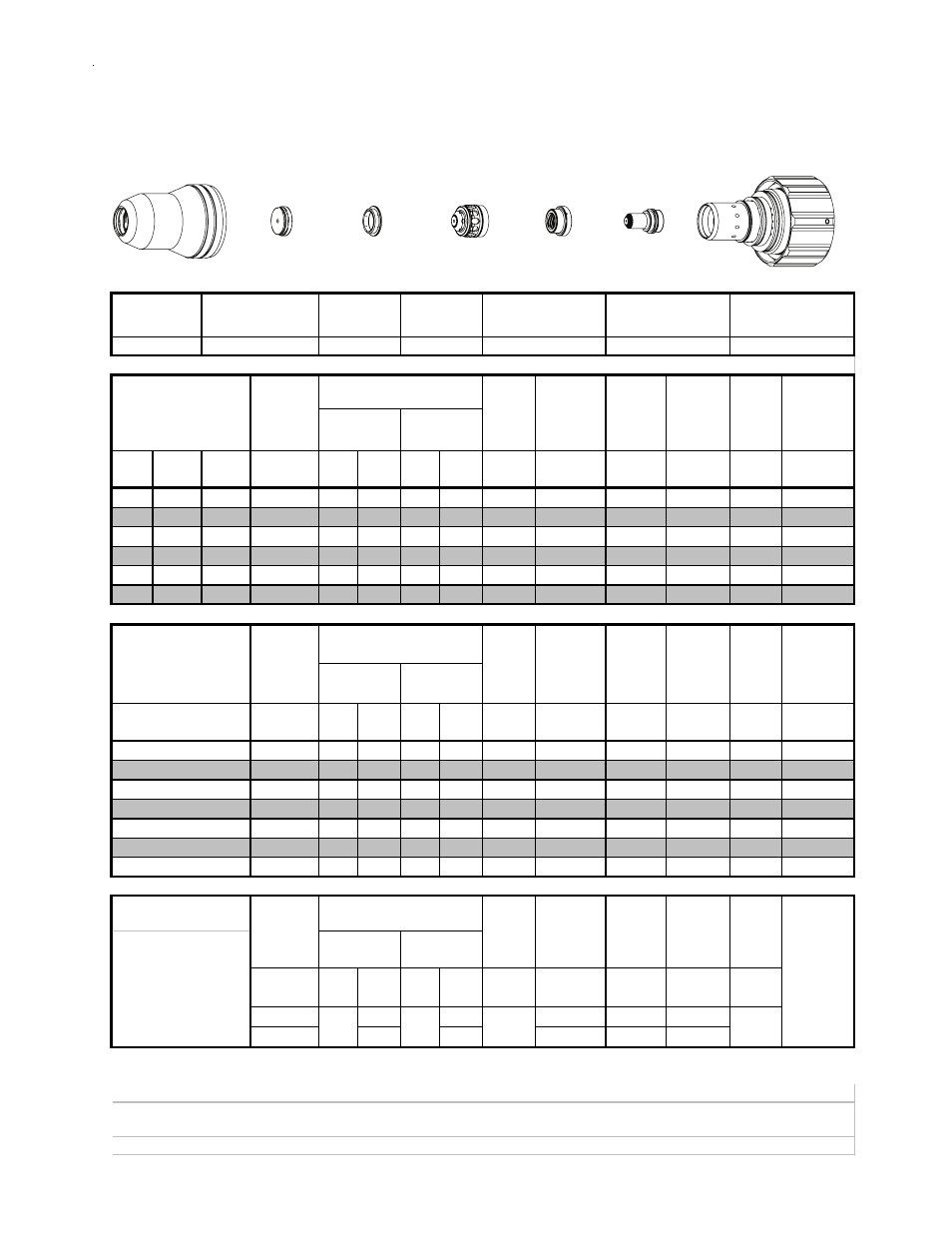

Aluminum 70a n, Plasma / h, O shield – Tweco XT-300 Torch for OEM UC-300 User Manual

Page 21: This art is for reference only

Manual 0-4829 Rev AN

8-23

TORCH DATA for Ultra-Cut

(ga)

(in)

inch

(PSI)

Ball (PSI) Ball (PSI)

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

16

0.064

45

55

90

5

55

155

0.100

300

0.250

0

0.057

14

0.079

45

55

90

5

55

148

0.100

240

0.250

0

0.068

12

0.097

45

55

90

5

55

150

0.150

200

0.250

0.1

0.095

3/16

0.188

45

55

90

5

55

150

0.150

120

0.250

0.3

0.095

1/4

0.250

45

55

90

5

55

158

0.150

70

0.250

0.3

0.097

3/8

0.375

45

55

90

5

55

162

0.150

35

0.250

0.5

0.100

(Bar)

Ball (Bar) Ball (Bar)

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

3.1

55

6.2

5

3.8

148

2.5

6100

6.3

0

1.7

3.1

55

6.2

5

3.8

150

3.8

4610

6.3

0.2

2.4

3.1

55

6.2

5

3.8

150

3.8

3730

6.3

0.3

2.4

3.1

55

6.2

5

3.8

151

3.8

2870

6.3

0.3

2.4

3.1

55

6.2

5

3.8

156

3.8

2060.3

6.3

0.3

2.5

3.1

55

6.2

5

3.8

160

3.8

1315

6.3

0.4

2.6

3.1

55

6.2

5

3.8

163

3.8

880

6.3

0.5

2.7

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

Volts

in ±0.005 /

mm ±0.1

ipm /

mm/min

in ±0.005 /

mm ±0.1

(sec)

20

40

80

0.120

300

0.120

1.4

2.8

5.5

3.0

7600

3.0

150

0

Burn-through

may occur

for thicknesses

< 1/16" (0.063") / 1.6

mm.

Plasma (N

2

) Shield (N

2

)

50

75

Marking

18A Arc Current

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Transfer

Height

Pierce

Delay

Marking

quality

degrades

as

thickness

decreases

Aluminum

70A

N

2

Plasma / H

2

O Shield

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Electrode

Cartridge

22-1041

22-1084

22-1020

22-1016

22-1047

22-1274

22-1064

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

Plasma (N

2

)

Shield

(H

2

O)*

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

Plasma (N

2

)

Shield

(H

2

O)*

(mm)

2

3

4

5

6

7

8

Note2: Water source used for shield must be demineralized.

BOLD TYPE indicates maximum piercing parameters.

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later

* Pressure of the water supply line should be regulated by customer pressure regulator.

Note1: Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with the

ohmic sensing circuit.

Electrode

Shield Cap

Tip

Shield Gas

Distributor

Plasma Gas

Distributor

Cartridge

Shield Cup

This Art Is For Reference ONLY

Art # A-07958_AB