Shield – Tweco XT-300 Torch for OEM UC-300 User Manual

Page 42

TORCH DATA for Ultra-Cut

8-44

Manual 0-4829 Rev AN

(ga)

(in)

inch

psi

Ball

psi

Ball

psi

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

1/2

0.500

70

80

120

60

120

167

0.400

75

0.450

0.4

0.120

5/8

0.625

70

80

120

60

120

165

0.300

40

0.350

0.5

0.129

3/4

0.750

70

80

120

60

120

173

0.300

35

0.400

0.8

0.139

1

1.000

70

80

120

60

120

175

0.300

25

0.450

1.8

0.137

bar

Ball

bar

Ball

bar

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

4.8

80

8.3

60

8.3

167

10.2

2100

11.4

0.4

3.0

4.8

80

8.3

60

8.3

165

7.6

1260

8.9

0.5

3.2

4.8

80

8.3

60

8.3

173

7.6

850

10.2

0.8

3.5

4.8

80

8.3

60

8.3

175

7.6

650

11.4

1.8

3.5

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

Volts

in ±0.005 /

mm ±0.1

ipm /

mm/min

in ±0.005 /

mm ±0.1

(sec)

20

60

80

0.120

300

0.120

1.4

4.1

5.5

3.0

7600

3.0

Pierce

Delay

Marking

quality

degrades

as

thickness

decreases

Burn-through

may occur

for thicknesses

< 1/16" (0.063") / 1.6

mm.

Plasma (N

2

) Shield (N

2

)

60

75

130

0

22-1278

22-1063

Marking

19A Arc Current

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Transfer

Height

Aluminum

150A

H35 Plasma / N

2

Shield

BOLD TYPE indicates maximum piercing parameters.

25

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Shield (N

2

)

22-1041

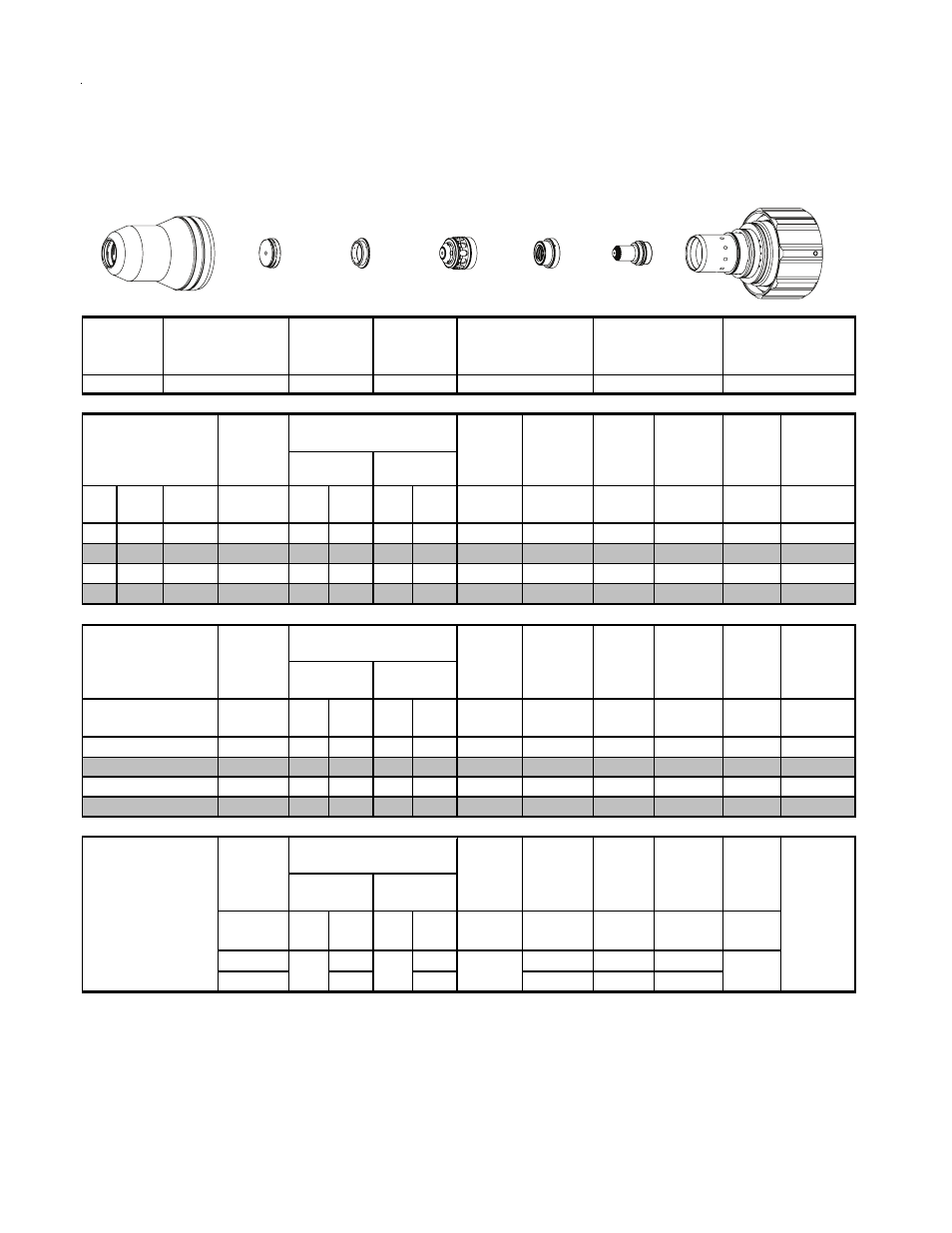

Plasma Gas

Distributor

Electrode

Cartridge

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

22-1016

22-1037

22-1081

22-1020

Torch

Working

Height

(mm)

12

20

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

15

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Kerf Width

@ Rec.

Speed

Plasma

(H35)

Shield (N

2

)

Kerf Width

@ Rec.

Speed

Plasma

(H35)

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Arc

Voltage

Electrode

Shield Cap

Tip

Shield Gas

Distributor

Plasma Gas

Distributor

Cartridge

Shield Cup

This Art Is For Reference ONLY

Art # A-07958_AB