Aluminium 30a n, Plasma / h, O shield – Tweco XT-300 Torch for OEM UC-300 User Manual

Page 11

Manual 0-4829 Rev AN

8-13

TORCH DATA for Ultra-Cut

(ga)

(in)

inch

(PSI)

(Ball) (PSI) (Ball) (PSI)

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

25

0.025

96

55

120

4

55

103

0.03

230

0.08

0

0.034

21

0.037

96

55

120

4

55

103

0.03

220

0.08

0.1

0.045

18

0.052

96

55

120

4

55

103

0.03

150

0.08

0.2

0.031

16

0.064

96

55

120

4

55

103

0.03

110

0.08

0.2

0.036

(Bar)

(Ball) (Bar) (Ball) (Bar)

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

6.6

55

8.3

4

3.8

103

0.8

5310

2.0

0.1

1.1

6.6

55

8.3

4

3.8

103

0.8

1550

2.0

0.2

1.0

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

Volts

in ±0.005 /

mm ±0.1

ipm /

mm/min

in ±0.005 /

mm ±0.1

(sec)

20

40

80

0.100

300

0.100

1.4

2.8

5.5

2.5

7600

2.5

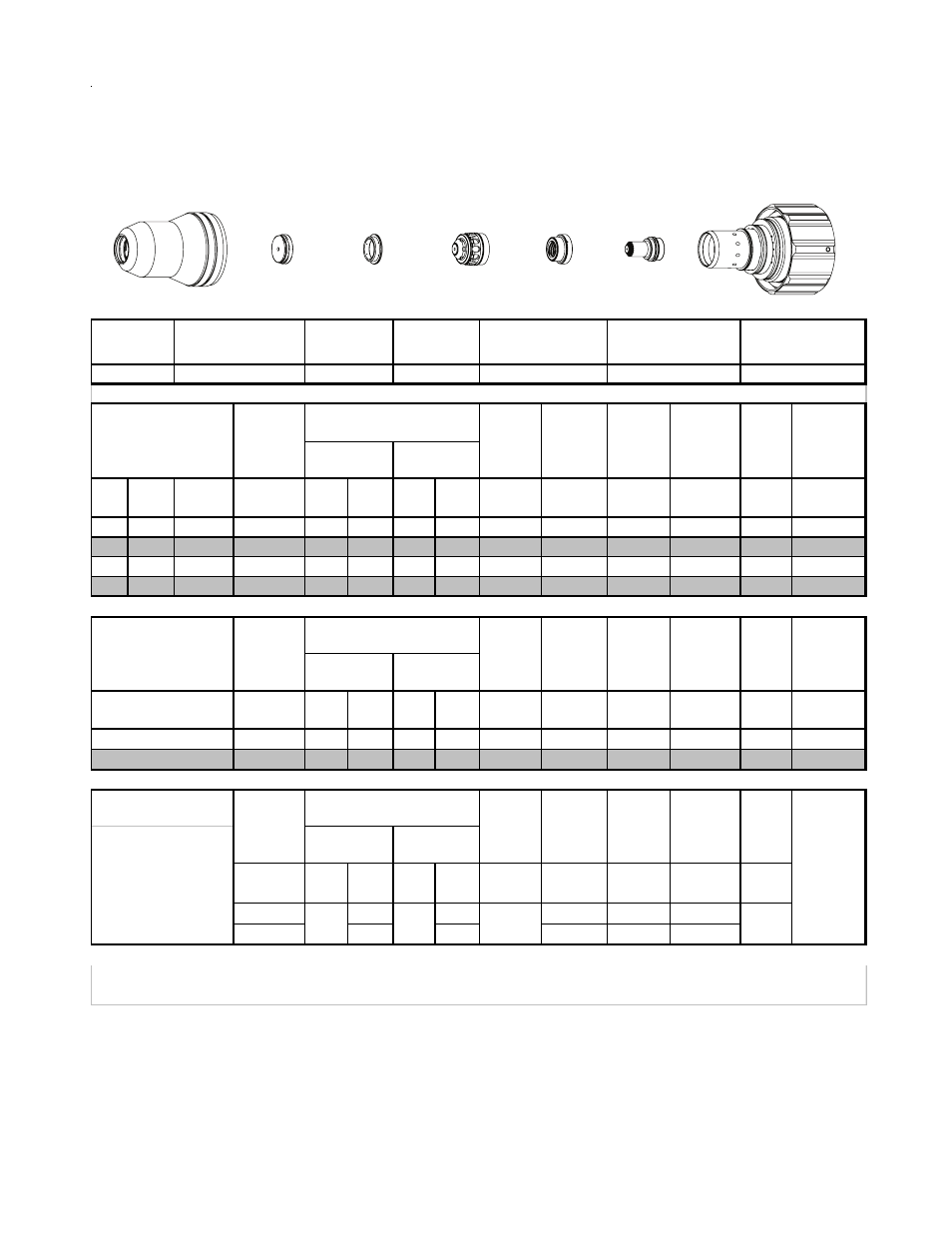

Aluminium

30A

N

2

Plasma / H

2

O Shield

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Electrode

Cartridge

22-1045

22-1077

22-1020

22-1016

22-1033

22-1274

22-1059

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

Plasma (N

2

) Shield (H

2

O)

Kerf Width

@ Rec.

Speed

Plasma (N

2

) Shield (H

2

O)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

(mm)

1

2

Pierce

Delay

Material

Thickness

Pre Flow

Pressure

(N

2

)

Initial

Piercing

Height

0

Marking

16A Arc Current

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Transfer

Height

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

Pierce

Delay

Marking

quality

degrades

as

thickness

decreases

Burn-through

may occur

for thicknesses

< 1/16" (0.063") / 1.6

mm.

Plasma (N

2

) Shield

(N

2

)

20

70

93

Electrode

Shield Cap

Tip

Shield Gas

Distributor

Plasma Gas

Distributor

Cartridge

Shield Cup

This Art Is For Reference ONLY

Art # A-07958_AB