Nozzle cleaning station – Tweco QRC-2000 User Manual

Page 20

nozzle cleaning station

6-18

SM-QRC-2000

tRoubleShooting

SECTION 6:

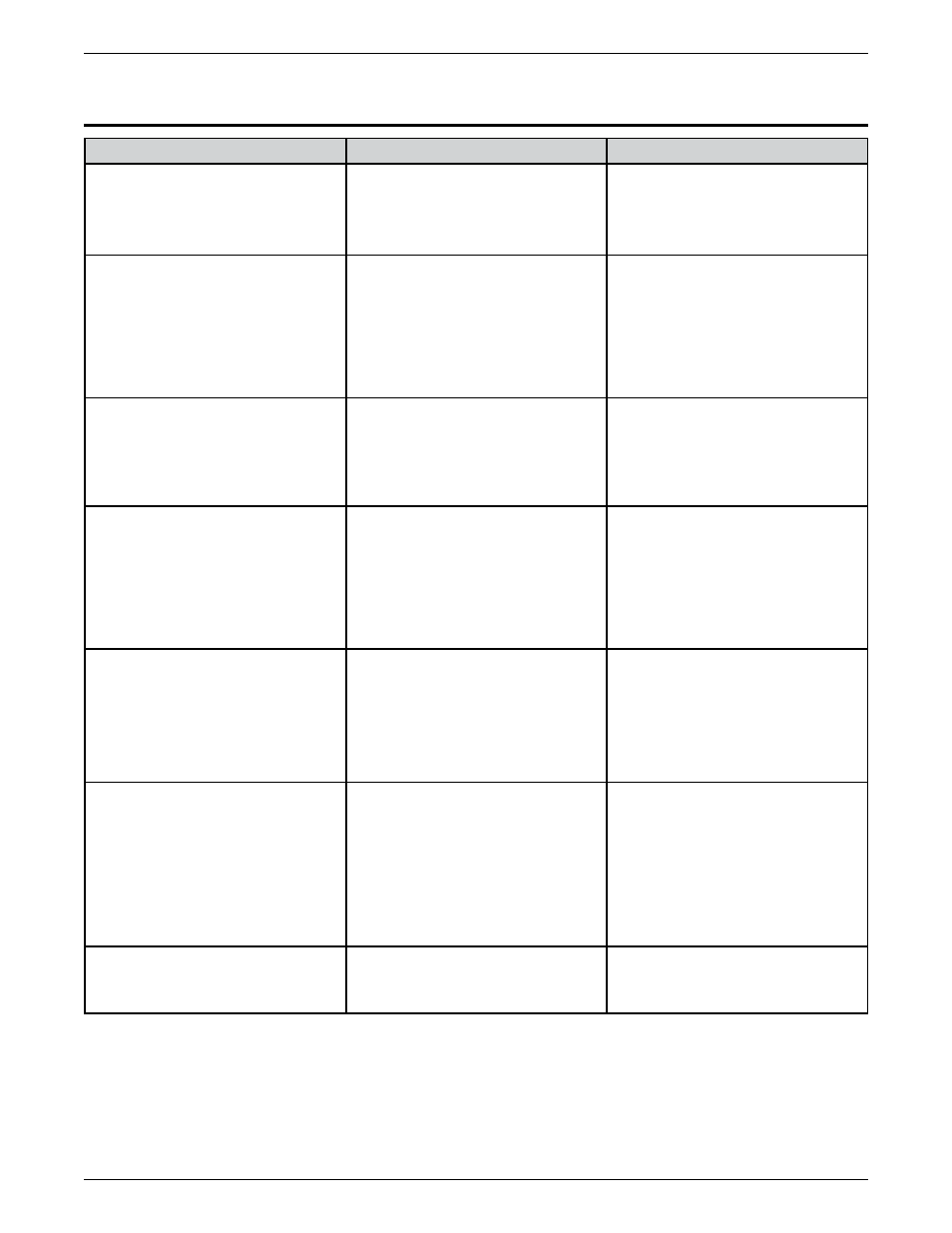

TROUBLESHOOTING

Problem

Cause

Solution

LED signals not activating

1. The unit is not receiving power.

1. Turn power on.

2. The unit is not getting air.

2. Turn air on.

3. Input voltage is incorrect.

3. Check input voltage and change if

required.

Reamer Blade/Air Motor stops

during operation (see also

Pneumatic functions not operating

properly)

1. Cutter feed rate is too fast.

1. Reduce cutter feed rate (see

section 3.10).

2. Excessive spatter buildup.

2. Clean affected area and adjust weld

parameters. Apply or increase

anti-spatter. Clean more often.

3. Incorrect air supply.

3. Adjust air supply (See section

3.03).

Pneumatic functions not operating

properly

1. Incorrect air supply.

1. Adjust air supply (see section

3.03).

2. Air line damage or obstructed and

air leaks.

2. Check lines for leaks and replace

hose if damaged.

3. Faulty reset switch.

3. Repair or replace reset switch.

Broken Reamer Blade

1. Wrong size reamer blade or clamp

block.

1. Check sizing (see section 3.08).

2. Reamer blade feed rate was set

too high.

2. Reduce cutter feed rate. (see

section 3.10).

3. Excessive spatter buildup.

3. Clean affected area and adjust weld

parameters. Apply or increase

anti-spatter. Clean more often.

Reamer Blade stays in down position

1. Damaged lift cylinder or air lines. 1. Reset switch defective.

2. Faulty or contaminated lift solenoid. 2. Check solenoid valves. Fix or

replace faulty solenoid.

3. Reset switch defective.

3. Replace reset switch.

4. Damaged limit switch.

4. Identify and replace faulty

switch.

Reamer Blade stays in up position

1. Reamer Blade is jammed.

1. Press Reset button and Inspect

Reamer Blade.

2. Faulty air solenoid.

2. Replace air solenoid.

3. Bad or dirty lift cylinder.

3. Fix or replace cylinder.

4. Cycle start signal held on.

4. Adjust cleaning cycle program.

5. Faulty limit switch.

5. Replace limit switch.

Cycle complete signal does not

activate

1. Faulty limit switch on lift cylinder

or clamping cylinder.

1. R e p l a c e o r r e a l i g n r e a d

switch(es).

2. Unit is not wired correctly.

2. Check wiring (see section 4).