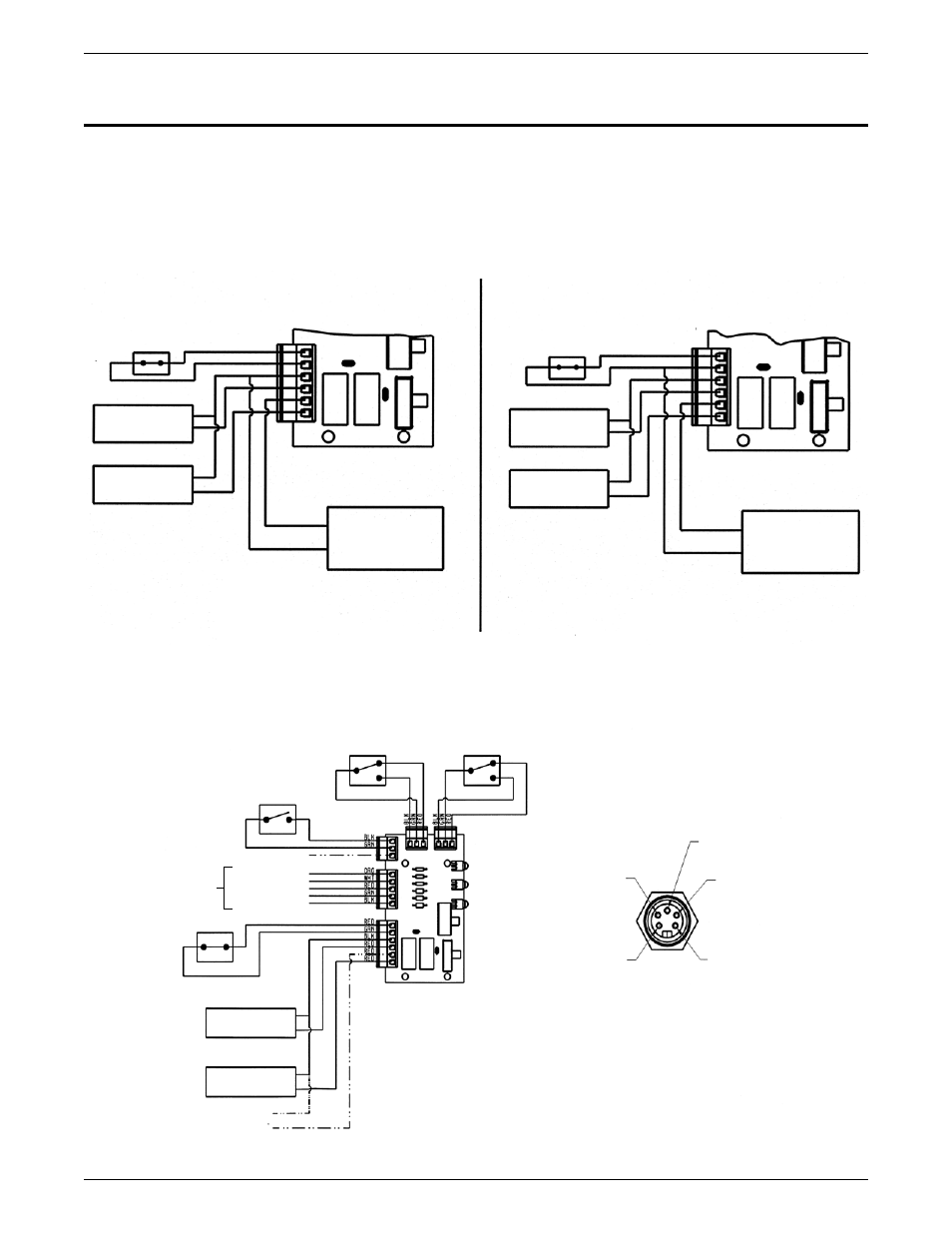

Nozzle cleaning station, 02 wiring diagram, Figure 12 – Tweco QRC-2000 User Manual

Page 15: Figure 11: pin #1 on top/pin #6 on bottom

nozzle cleaning station

4-13

SM-QRC-2000

WiRing And pneuMAtiC

SECTION 4:

WIRING AND PNEUMATIC

4.01 Wiring for the QRM-100 and QRM-3 Anti-spatter Mist Applicator

The drawings below show the QRM-100 and QRM-3 wiring connections.

For a sinking connection, the wires must be connected to positions 5 and 2. For sourcing connection, the wires

must be connected to positions 5 and 3.

To operate the QRM-100 Anti-Spatter Mist Applicator, a timed 24 V DC signal must be applied to the black lead

(spare) of the interface receptacle.

•

•

MOTOR & CLAMP

SOLENOID VALVE

SPINDLE LIFT

SOLENOID VALVE

PIN #5

PIN #3

ANTISPATTER UNIT

24DC

MOTOR & CLAMP

SOLENOID VALVE

SPINDLE LIFT

SOLENOID VALVE

PIN #5

PIN #2

ANTISPATTER UNIT

24DC

SOURCING

SINKING

4.02 Wiring Diagram

Figure 12

LOWER LIMIT

SWITCH

UPPER LIMIT

SWITCH

CLAMP

RETURN LIMIT

SWITCH

NOT USED

START SIGNAL

COMMON

+24VDC

JAWS UNCLAMPED

OPTIONAL EQUIPMENT

SEE 5 PIN

CONNECTOR

WIRING

RESET SWITCH

MOTOR AND CLAMP

SOLENOID VALVE

SPINDLE LIFT

SOLENOID VALVE

OPTIONAL

EQUIPMENT

PIN #4

(ORG) START

SIGNAL

PIN #5 (BLK)

OPTION

PIN #3

(GRN) JAWS

UNCLAMPED

PIN #2 (RED)

+24 VDC

PIN #1 (WHT)

COMMON

EXTERNAL VIEW OF 5-PIN CONNECTOR

Figure 11: Pin #1 on Top/Pin #6 on Bottom