Nozzle cleaning station – Tweco QRC-2000 User Manual

Page 18

nozzle cleaning station

5-16

SM-QRC-2000

MAintenAnCe

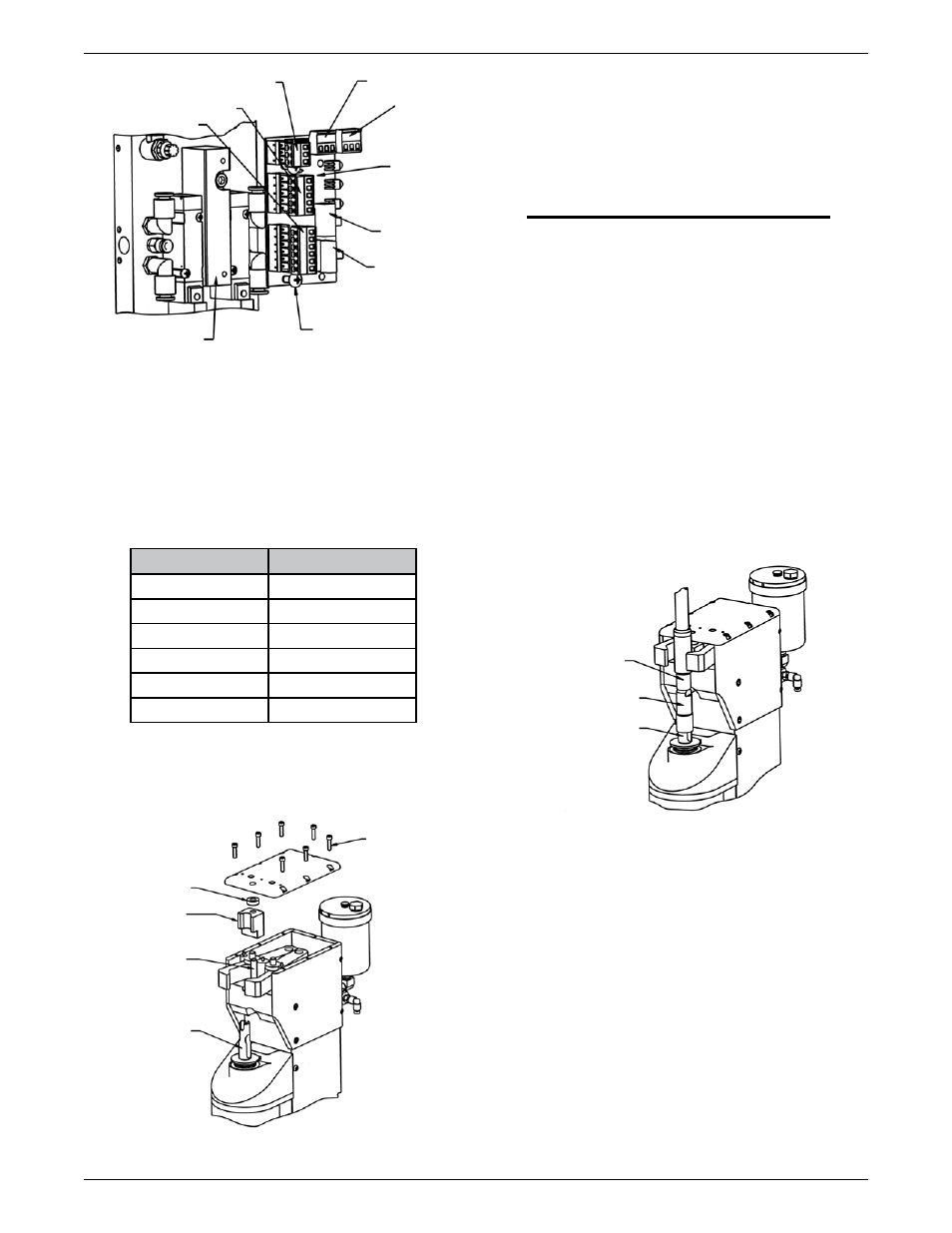

Clamp Block

Ensure that the power and air supply are off and

disconnected before replacing the clamp block.

Certain applications or normal wear may cause the need

to replace the QRC

TM

-2000 clamp block. There are five

clamp blocks available.

CIRCUIT BOARD

INSULATOR

NO. 10 S 1/2” LG.

THREAD-FORMING

SCREW (2 EA.)

SW1 SWITCH

SW2 SWITCH

CIRCUIT

BOARD

J5

CONNECTOR

Figure 17

J4 CONNECTOR

J3 CONNECTOR

J1 CONNECTOR

J2 CONNECTOR

Table 4: ORC

TM

-2000 Clamp Blocks List

Clamp Block O.D.

Fits Nozzles

QRC2102-A

.938” (23,8mm)

QRC2102-B

1” (25,4mm)

QRC2102-C

1.062” (27,0mm)

QRC2102-D

1.125” (28,6mm)

QRC2102-E

.875” (22,2mm)

QRC2102-F

.787” (20,0mm)

Clamp block “B” comes assembled on all QRC

TM

-2000

Nozzle Cleaning Station. The clamp blocks A, C, D, and E

are also supplied with the unit.

LOCATOR SPACER

CLAMP BLOCK

CLAMP BLOCK

LOCATOR PIN

REAMER BLADE

TOP PLATE

SCREWS (7 EA)

Figure 18

Remove the seven screws on three top plate.

Remove the top plate to the cleaning station.

Lift and rotate the clamp block so that the desired

sizes face the jaws.

Clean the components thoroughly and lubricate with

grease before reassembling them.

NOTE

part numbers are stamped on clamp blocks.

please refer to table 4 - QRC

tM

2000 clamp

block list for the outside diameter of the

nozzle.

•

•

•

•

QRC

TM

-2000 Reamer Blade

To remove the reamer blade, place the 9/16” (14mm)

spanner wrench, part no. QRC-440, on the hex flats

at the end of the extension shaft and the QRC-441

wrench on the top of the reamer blade.

The cutter is removed by turning counterclockwise

when viewed from above. Considerable force may be

required to loosen the reamer blade since it tightens

naturally as the reamer operates.

Please refer to Table 1 for reamer blade options.

•

•

•

T-WRENCH

REAMER BLADE

9/16” SPANNER

WRENCH

Figure 19