Nozzle cleaning station, 04 qrc, 2000 wiring interface – Tweco QRC-2000 User Manual

Page 10

nozzle cleaning station

3-8

SM-QRC-2000

inStAllAtion And opeRAtion

3.03 Air Supply, Connections, and

Lubrication Requirements

The air supply for the QRC

TM

-2000 nozzle cleaning station

should be filtered, unlubricated air. This unit requires 80-

100 PSI @ 8 CFM (5.5 – 6.8 BAR @ 225 LPM). The air

supply line should be a minimum of 1/4” I.D. with a male

1/4” NPT connection to fit the female connection in the

side of the logic cover. The air motor is lubricated through

a servo meter located below the lubricator reservoir.

The servo meter injects a quantity of oil directly into

the solenoid valves and air motor during each cleaning

cycle. The lubrication should be done using a light grade

hydraulic oil with a viscosity rating of 150 VC 15-20 (SAE

5W). When filling the reservoir for the first time or refilling

an empty reservoir, you must manually prime the pump to

distribute the oil through the system. The servo meter has

an adjustment that goes from 0 (-) to 45 (+) clicks and a

push button to prime the lubricant oil. Refer to Figure 2.

Pull the servo meter knob to the unlock position (A).

Set the servo meter knob at 45 (+) and press the button

appromimately 50 to 60 times.

Turn the servo meter knob counter-clockwise to 0 (-)

and set at 3 (+) clicks.

Push the servo meter knob back into the locked position (C).

The amount of lubricant can be adjusted by turning the

adjustment knob located on the servo meter.

•

•

•

•

LUBRICATOR

RESERVOIR

SERVO

METER

Figure 2

SERVO

METER

KNOB

PRIMER

PUSH

BUTTON

NOTE

Do not run unit without lubricant oil. if unit runs

out of lubricant oil, the motor will lock up and

the solenoid valves will stick. When lubricant

oil is added you must prime the unit and check

operation of the solenoid valves. permanent

damage can be caused to the solenoid valves if

the unit is allowed to run out of lubricant oil.

NOTE

lubricator Reservoir oil must have a vent in the

open position. if not, oil will not flow.

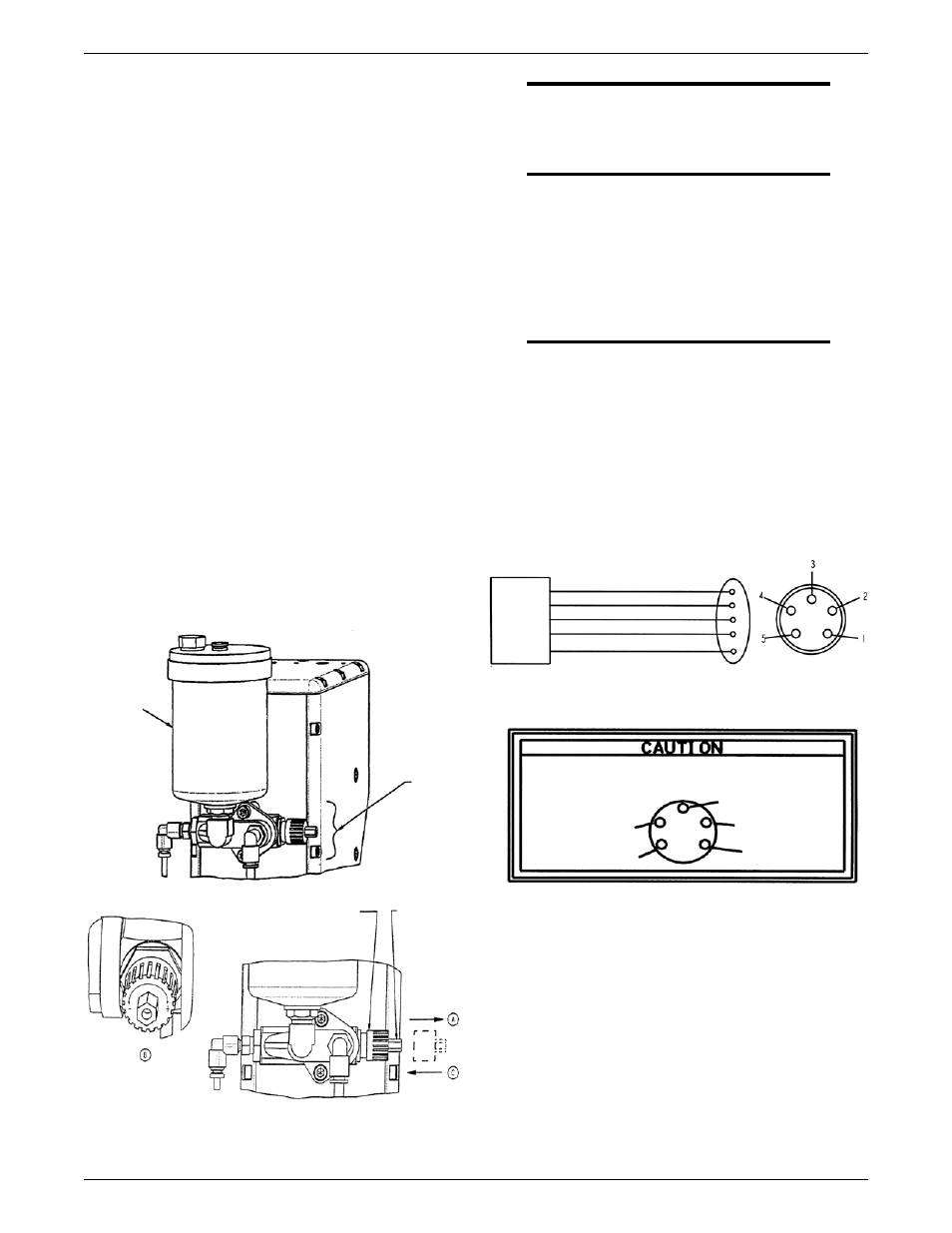

3.04 QRC

TM

-2000 Wiring Interface

The QRC

TM

-2000 Nozzle Cleaning Station wiring interface

requires a five wire connection. Each wire is color-coded.

The drawing below shows the wire color to its connector

pin/socket number and function.

The Following Connections are Required for Proper

Unit Operation:

Red Lead Connection: Operates internal logic with

a +24 V DC supply.

Green Lead Connection: Cycle complete output

signal (+24 V DC for sourcing logic signal; 0 V DC

for sinking logic signal).

White Lead Connection: Supply common.

Orange Lead Connection: Cycle start input signal

+24 V DC for sourcing logic signal; 0 V DC for sinking

logic signal. (.5 - 1.0 second pulse signal)

Black Lead: Spare wire (optional connection).

•

•

•

•

•

NOTE

the QRC2000 nozzle cleaning station is factory

preset at 3 (+) clicks.

TURN

(ADJUST)

RED: +24 VOLTS DC SUPPLY

GREEN: UNCLAMP SYMBOL

WHITE: SUPPLY COMMON

ORANGE: +24 VOLTS DC START SIGNAL

BLACK: SPARE/OPTION

4. START SIGNAL

(ORANGE)

5. OPTION

(BLACK)

ENSURE PROPER INTERFACE hAS BEEN MADE OR DAMAGE

MAY OCCUR

2. +24 VDC

SUPPLY (READ)

1. COMMON

(WHITE)

3. JAWS UNCLAMPED

(GREEN)

Figure 3

ROBOTIC

CONTROL