Nozzle cleaning station, 05 electrical and pneumatic controls access, 06 logic inverse – Tweco QRC-2000 User Manual

Page 11: 07 led indicators

nozzle cleaning station

3-9

SM-QRC-2000

inStAllAtion And opeRAtion

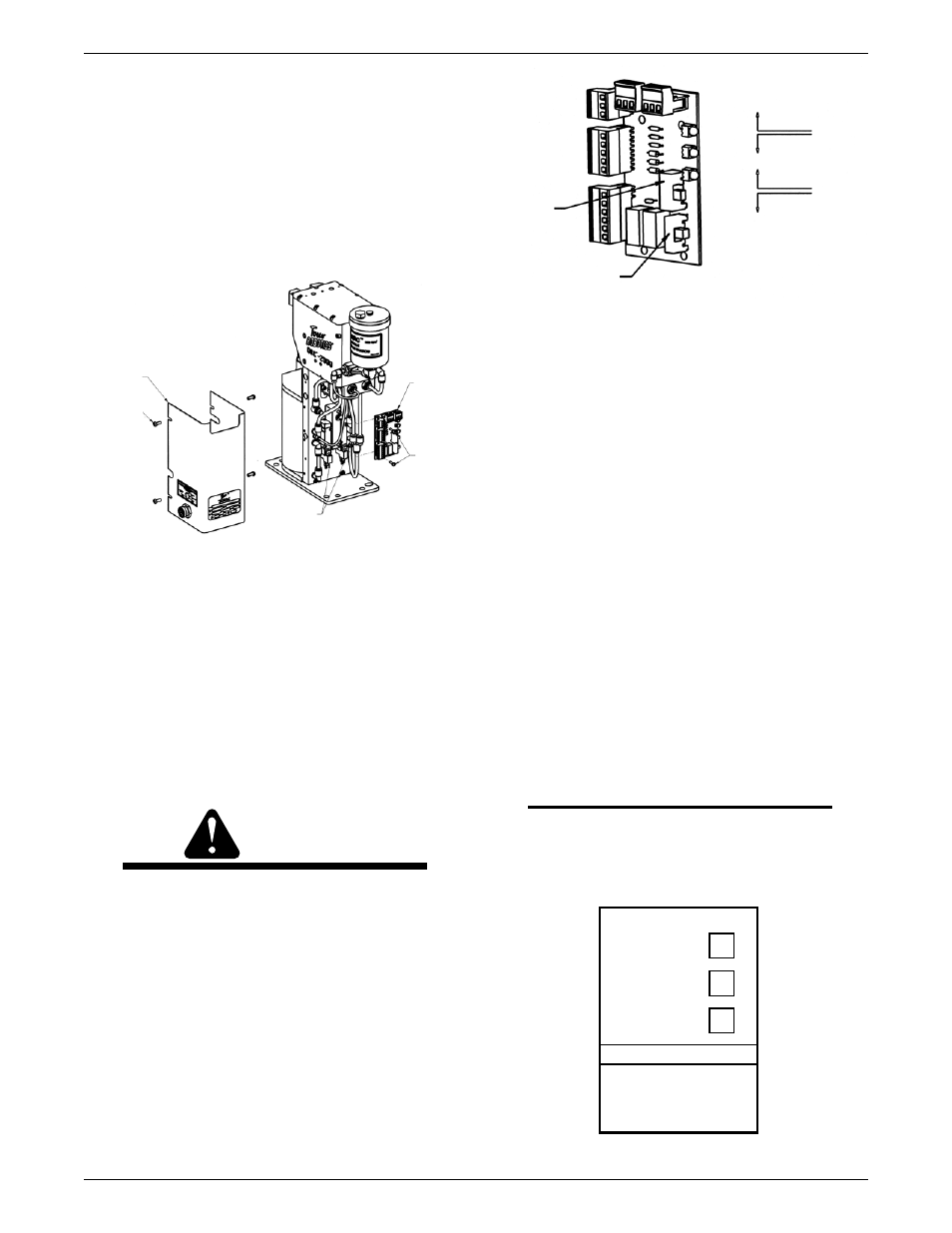

3.05 Electrical and Pneumatic Controls

Access

Ensure that the power is off and disconnected, and air

supply is off before removing logic cover.

To gain access to the circuit board and pneumatic manifold,

the logic cover must be removed. To free the logic cover

loosen four 10-24 button head screws and slide cover

away from cleaning station being careful not to disconnect

the interface connections from circuit board.

3.06 Logic Inverse

The QRC

TM

-2000 Nozzle Cleaning Station comes from the

factory set for sourcing (high) +24 V DC input or output.

Some installations may require the opposite of this or 0

V DC sinking (low) input or output.

Accessing the circuit board is necessary to switch from

sourcing to sinking input/output. On the lower right hand

corner of the circuit board are two switches that need to be

set to correspond to the input/output signal requirement

as shown.

CAUTION

do not switch circuit board sourcing and

sinking switches with power on. damage will

occur. only move switches with power off.

To operate the unit ON sinking connection, switch SW1

must be in the down position, and switch SW2 must

be in the up position. To operate the unit ON sourcing

connection, reverse the position of the switches. Refer

to diagram shown on Figure 5.

SW2

SWITCH 2 (SW2) OUTPUT

JAWS UNCLAMPED

SINKING (UP)

SOURCING (DOWN)

SOURCING (UP)

SINKING (DOWN)

SWITCH 1 (SW1) INPUT START

SIGNAL

SW1

Figure 5

3.07 LED Indicators

The LED indicators located on the side of the logic

cover, supply visual information regarding cycle status.

This information may be used for both installation and

maintenance to verify proper operation. The LED indicates

the cleaning sequence as follows:

Unclamped - On

Indicates that the clamp cylinder is fully extended, opening

the nozzle clamp block and supplying an output signal that

the reamer cycle is complete.

Reamer Ahead - Off

Indicates that the lift cylinder is fully extended putting the

reamer blade at the top of its reaming stroke and activating

the upper limit switch on the circuit board.

Reamer home - On

Indicates that the lift cylinder has fully retracted, placing

the reamer blade at the bottom of its stroke (home

position), and has activated the lower limit switch on the

circuit board.

NOTE

both the unclamped and Reamer home lights

must be on for the unit to start the cleaning

process.

CLEANING SEQUENCE

UNCLAMPED

REAMER AHEAD

REAMER HOME

CAUTION

ENSURE PROPER INTERFACE

HAS BEEN MADE OR DAMAGE

MAY OCCUR. READ TECHNICAL

GUIDE BEFORE START-UP.

Figure 6

LOGIC

COVER

NO. 10-24

X 1/2” LG.

BUTTON

HEAD

SCREW

(4 EA.)

SOLENOID

VALVE (2 EA)

CIRCUIT

BOARD

NO. 10-24

X 1/2” LG.

BUTTON

HEAD

SCREW (4

EA.)

NO.

10X1/2”

LG

THREAD

FORMING

SCREW

(2 EA)

Figure 4