Nozzle cleaning station, 01 maintenance schedule, 02 component replacement instructions – Tweco QRC-2000 User Manual

Page 17

nozzle cleaning station

5-15

SM-QRC-2000

MAintenAnCe

SECTION 5:

MAINTENANCE

5.01 Maintenance Schedule

The QRC

TM

-2000 will require a periodic maintenance

schedule to ensure an optimum service life. The following

maintenance checks are required. Depending on the use

of the unit, each specific application could require a more

extensive schedule.

Daily

Ensure incline housing area is clear of excessive

spatter.

Visually check oil level in lubricator reservoir.

Weekly

Ensure incline housing area is clear of excessive

spatter.

Visually check lubricating oil level in lubricator

reservoir. The life of the air motor is dependent on

a sufficient supply of lubricating oil. Replenish this

oil as needed.

Inspect air lines and connections for leaks.

Check interface cables for frayed connections or

bad wiring.

Quarterly

The QRC

TM

-2000 reamer blade life will depend on the

application.

At least quarterly the reamer blade should be inspected

for dullness, clogging and breakage.

Visually check lubricating oil level in lubricator reservoir.

Ensure incline housing area is clear of excessive spatter.

Yearly

The clamp block should be cleaned and inspected

for excessive wear and replaced if needed.

Visually check lubricating oil level in lubricator

reservoir. Replenish this oil as needed.

Inspect air lines and connections for leaks.

Check interface cables for frayed connections or

bad wiring.

Remove top plate and apply grease on cam slides

on top (V-Block) and side plates.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

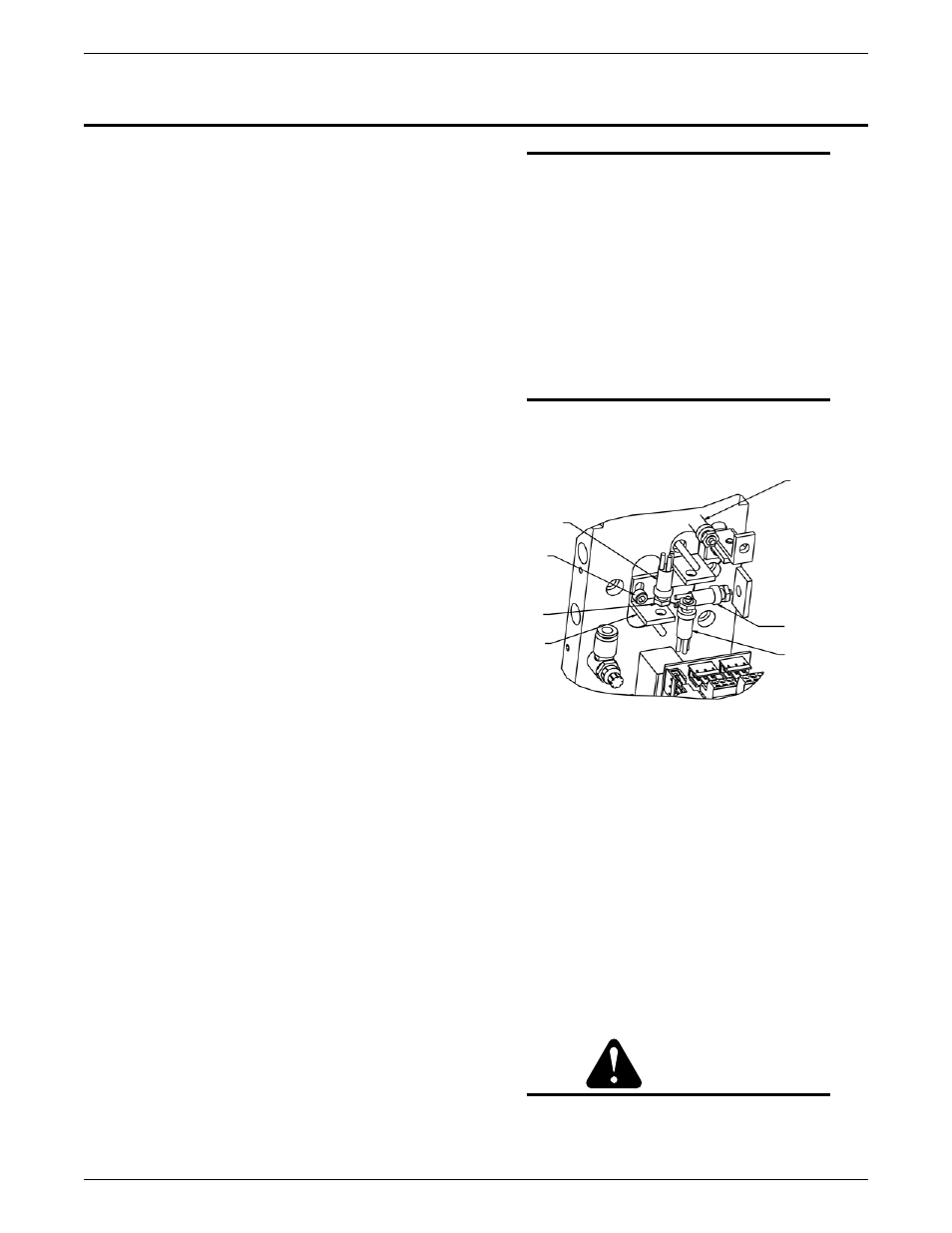

5.02 Component Replacement Instructions

Upper, Lower, and Jaw Stop Limit Switches

Ensure that the power is off and disconnected, and the air

supply is off before replacing the limit switches.

To replace the limit switches, loosen the screws that

connect the limit switch bracket to the manifold.

Disconnect the wiring for the limit switch that is being

replaced.

Remove the nut that connects the limit switch to the limit

switch bracket.

Replace the limit switches in reverse order

•

•

•

•

NOTE

be sure to review the wiring diagram when

rewiring and disconnecting the limit switch (see

figure 12). the limit switches are adjusted at

the factory. if an adjustment needs to be made,

please contact our factory technical center.

Reset Switch

Unscrew the nut that connects the limit switch to

bracket.

Disconnect the wiring from the circuit board and

replace it.

NOTE

be sure to review the wiring diagram (figure

12) when rewiring and disconnecting the reset

switch.

•

•

Circuit Board

Ensure that the power and air supply are off and

disconnected before replacing the circuit board.

Replace the circuit board in the following manner:

Once the power and air are disconnected from the

QRC

TM

-2000, carefully unplug all connectors from

the board.

Unscrew the two screws located on the circuit board.

(Fig. 17) The circuit board can now be replaced.

Install the new circuit board on the board insulator.

Once this has been completed, tighten the two circuit

board mounting screws.

Reconnect the connectors while referring to wiring

diagram to be sure the connections are in the

proper location.

CAUTION

Do not switch circuit board sourcing and

sinking switches with the power on. damage

will occur. only move the switches with the

power off.

•

•

•

•

•

LOWER

LIMIT

SWITCH

BRACKET

SCREW

LOCKING

NUT

SWITCH

BRACKET

JAW CLAMP

LIMIT

SWITCH

RESET

SWITCH

UPPER LIMIT

SWITCH

Figure 16