Nozzle cleaning station, 09 tweco, Robotic nozzles vs. clamp block – Tweco QRC-2000 User Manual

Page 13: 10 air flow control valve, 11 nozzle and insertion parameter

nozzle cleaning station

3-11

SM-QRC-2000

inStAllAtion And opeRAtion

The other variable part in the QRC

TM

-2000 Nozzle Cleaning

Station is the clamp block set. There are five clamp blocks

available. Please refer to Tables 2 and 3.

The clamp block “B” comes assembled on all QRC

TM

-2000

Nozzle Cleaning Station. Clamp blocks A, C, D, and E are

also supplied with the unit.

Table 2: QRC

TM

-2000 Clamp Blocks List

Clamp Block O. D.

Fits Nizzels

QRC2102-A

.938” (23,8mm)

QRC2102-B

1” (25,4mm)

QRC2102-C

1.062” (27,0mm)

QRC2102-D

1.125” (28,6mm)

QRC2102-E

.875” (22,2mm)

QRC2102-F

.787” (20,0mm)

Table 3: Tweco

®

Robotic Nozzles vs. Clamp Block

Nozzle

Nozzle O.D.

Clamp Block

REL21 Series

.875” (22,2mm)

QRC-2102-E

REL24CT Series 1” (25,4mm)

QRC-2102-B

RWC24 Series

1” (25,4mm)

QRC-2102-B

RWC26 Series

1.062” (27,0mm)

QRC-2102-C

3.09 Tweco

®

Robotic Nozzles vs. Clamp Block

Program the robot to position the Mig nozzle directly above

and centered to the reamer blade above the QRC

TM

-2000.

Insert the nozzle to the required depth to allow complete

cleaning of the tip and nozzle without damaging the torch

consumable parts. (Please refer to section 3.11).

At this time the cycle start signal (pulse .5 to 1.0 seconds)

should be sent to the QRC

TM

-2000 from the robotic

controller. Then the QRC

TM

-2000 will clamp the nozzle and

perform the cleaning operation.

Once the reamer completes the cleaning cycle, the cleaning

station will send a cycle complete signal back to the robot

controller. At this time, the torch is removed from the

QRC

TM

-2000 and the work cycle continues.

3.10 Air Flow Control Valve

The air flow control valve provides an adjustment for the

reamer blade feed rate. The amount of spatter buildup

will determine the required reamer blade feed rate. The

heavier the spatter, the slower the reamer blade feed

rate that should be used. If a smaller amount of spatter

accumulates, the feed rate can be set faster.

Adjusting the air flow control valve:

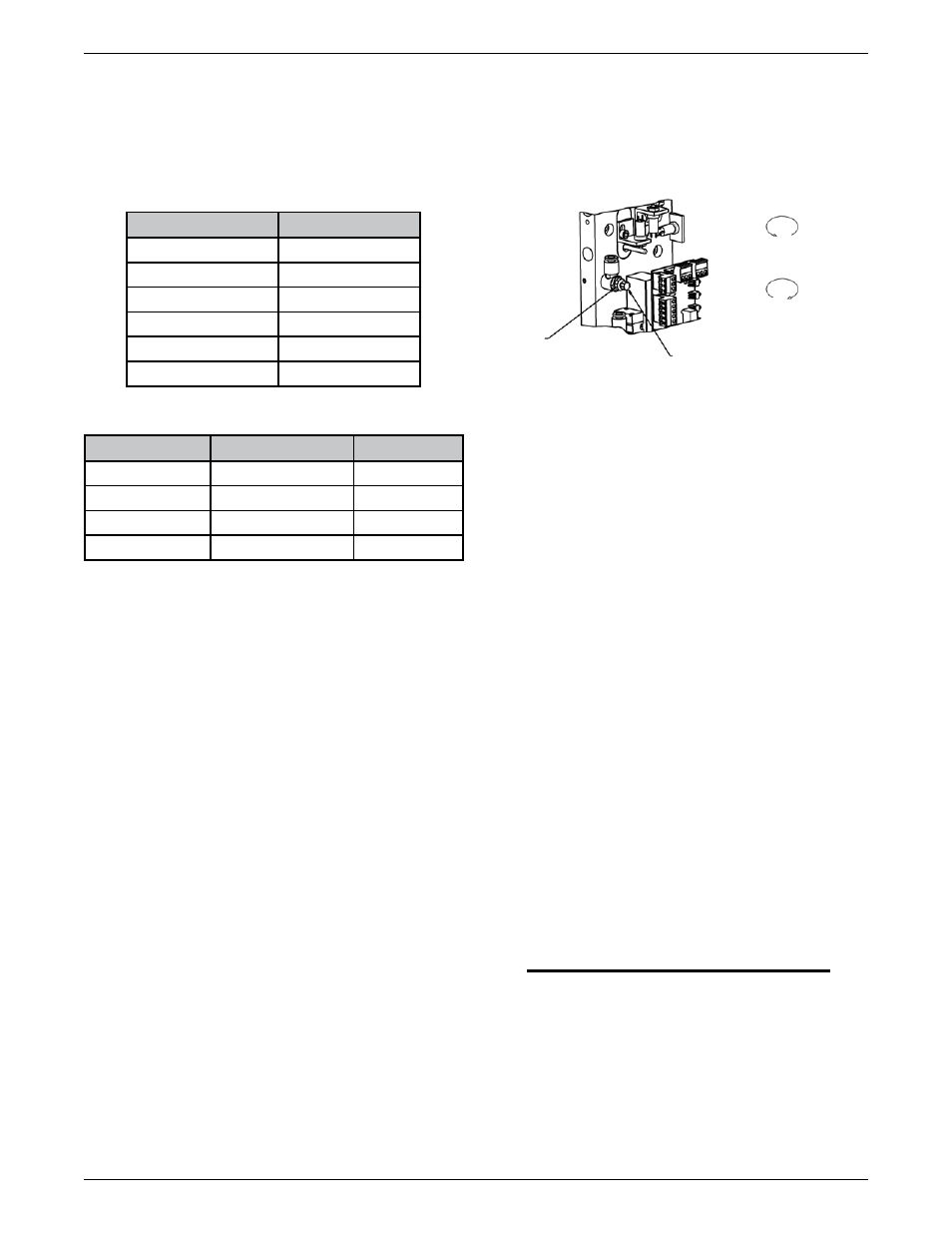

There is an air flow control valve inside the unit as

shown in Figure 8.

The feed rate may require adjusting for different

applications.

•

•

ADJUSTING

KNOB

LOCKING

NUT

INCREASE

FEED RATE

DECREASE

FEED RATE

Figure 8

3.11 Nozzle and Insertion Parameter

All QRC

TM

-2000 Nozzle Cleaning Stations come from

Tweco

®

Robotics with the QRC-100 reamer blade

(.620”/15,7mm O.D. x .422” / 10,7mm I.D.) and clamp

block “B” (QRC2102-B / 1”(25,4mm)).

Please make sure that the reamer blade and clamp block

fit the need of your application.

Setting up the Torch with Gauges

There are three sizes of gauges (1/2” (12,7mm), 5/8”

(15,9mm) and 3/4” (19,1mm)). These gauges are

available as a set under Part No. QRC

TM

-PG2.

Determine O.D. of reamer blade being used.

Slip proper gauge on O.D. of reamer blade.

Screw in tip index shaft.

Determine O.D. of contact tip being used.

Slip proper alignment sleeve on pointer.

Bring torch down to where the I.D. of contact tip

touches pointer, push alignment sleeve up and over

contact tip to gauge if torch is set at 90 degrees.

Once this is established, back the torch off from the

pointer to allow room to remove the pointer and

alignment sleeve.

Bring the torch back down to where the nozzle

touches top of the gauge.

This allows the programmer to set up for the stroke

of the reamer blade in the cleaning sequence.

NOTE

using a flush or protruded nozzle, adjust the

reamer blade stroke, leaving a gap between

the nozzle and the top of the gauge. for

flush nozzles: leave a 1/8” (3,2mm) gap.

for protruded nozzles: leave a 1/4” (6,4mm)

gap.

•

•

•

•

•

•

•

•

•

•

To increase the reamer blade feed rate, unscrew the

nut and rotate the valve knob counter-clockwise.

After the adjustment, lock the valve knob nut.

To decrease the reamer blade feed rate, unscrew the

nut and rotate the valve knob clockwise. After the

adjustment, lock the valve knob nut.

•

•