Transmig 400 i – Tweco 400i Transmig User Manual

Page 47

TRANSMIG 400 i

6-7

July 18, 2008

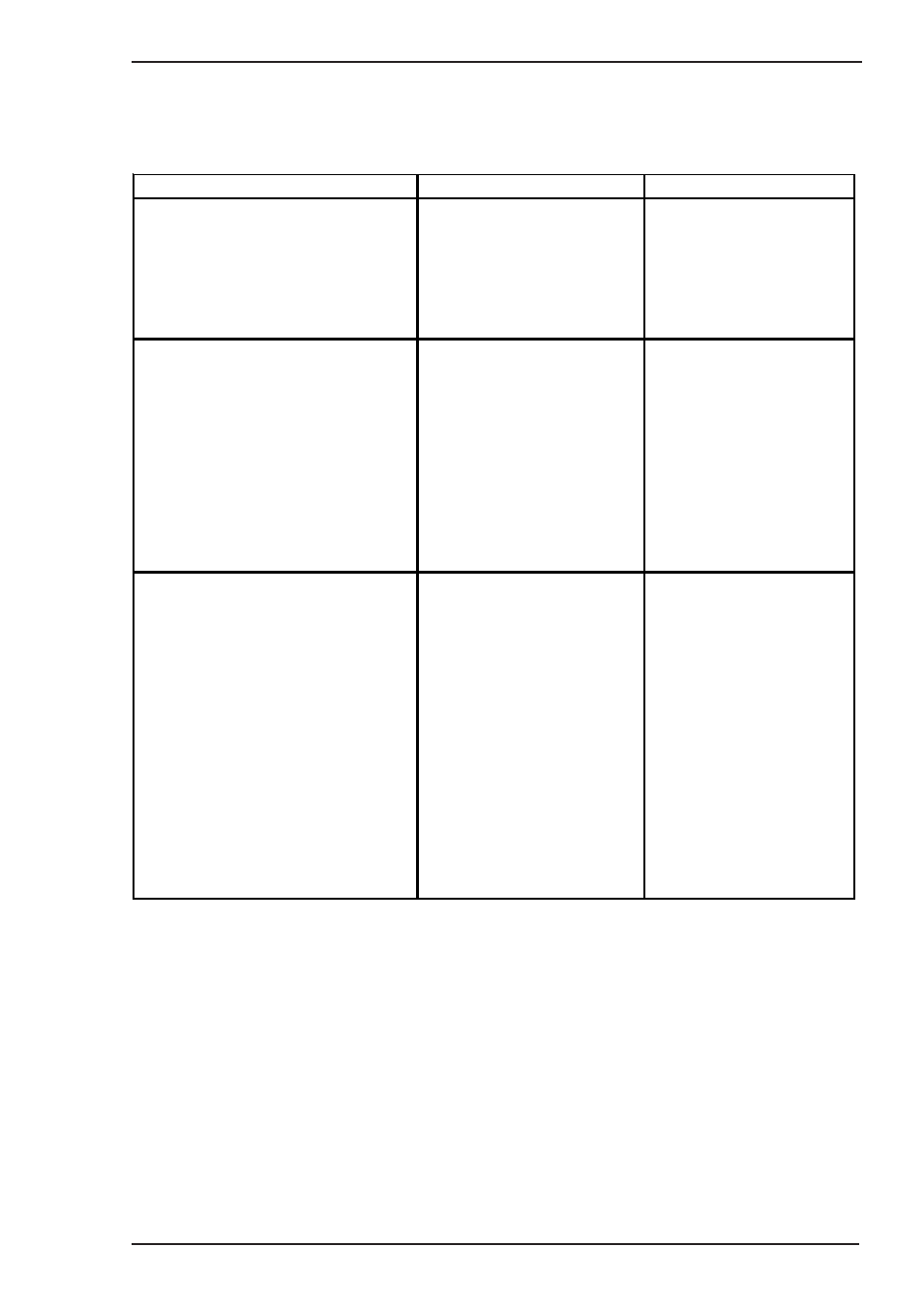

10 Arc flutters during TIG welding

A Tungsten electrode is too

large for the welding current

A Select the right size

electrode. Refer to Basic

TIG Welding Guide

B Absence of oxides in the

weld pool

B Refer to Basic TIG

Welding Guide for ways to

reduce arc flutter

11 Welding arc cannot be established A Work clamp is not

connected to the work piece

or the work/torch leads are

not connected to the right

terminals

A Connect the work clamp

to the work piece or

connect the work/torch

leads to the right welding

terminals

B Torch lead is disconnected

B Connect it to the '-'

terminal

C Gas flow incorrectly set,

cylinder empty or the torch

valve is off

C Select the right flow rate,

change cylinders or turn

torch valve on

12 Arc start is not smooth

A Tungsten electrode is too

large for the welding current

A Select the right size

electrode. Refer to Basic

TIG Welding Guide

B The wrong electrode is

being used for the welding

job

B Select the right size

electrode. Refer to Basic

TIG Welding Guide

C Gas flow rate is too high

C Select the correct rate for

the welding job. Refer to

Basic TIG Welding Guide

D Incorrect shielding gas is

being used

D Select the right shielding

gas. Refer to Basic TIG

Welding Guide

E Poor work clamp

connection to work piece

E Improve connection to

work piece

Possible Cause

Description

Remedy