Transmig 400 i, 08 set-up for gmaw/fcaw (mig) – Tweco 400i Transmig User Manual

Page 31

TRANSMIG 400 i

July 18, 2008

4-9

4.08 Set-up for GMAW/FCAW (MIG)

MIG welding with the Transmig 400 i requires the integration of a constant voltage (CV) wire feeder. Shielding

gas will also usually be required in most cases except for some flux cored welding operations (FCAW). When

setting up for flux cored welding, contact the welding wire manufacturer for lead polarity recommendations.

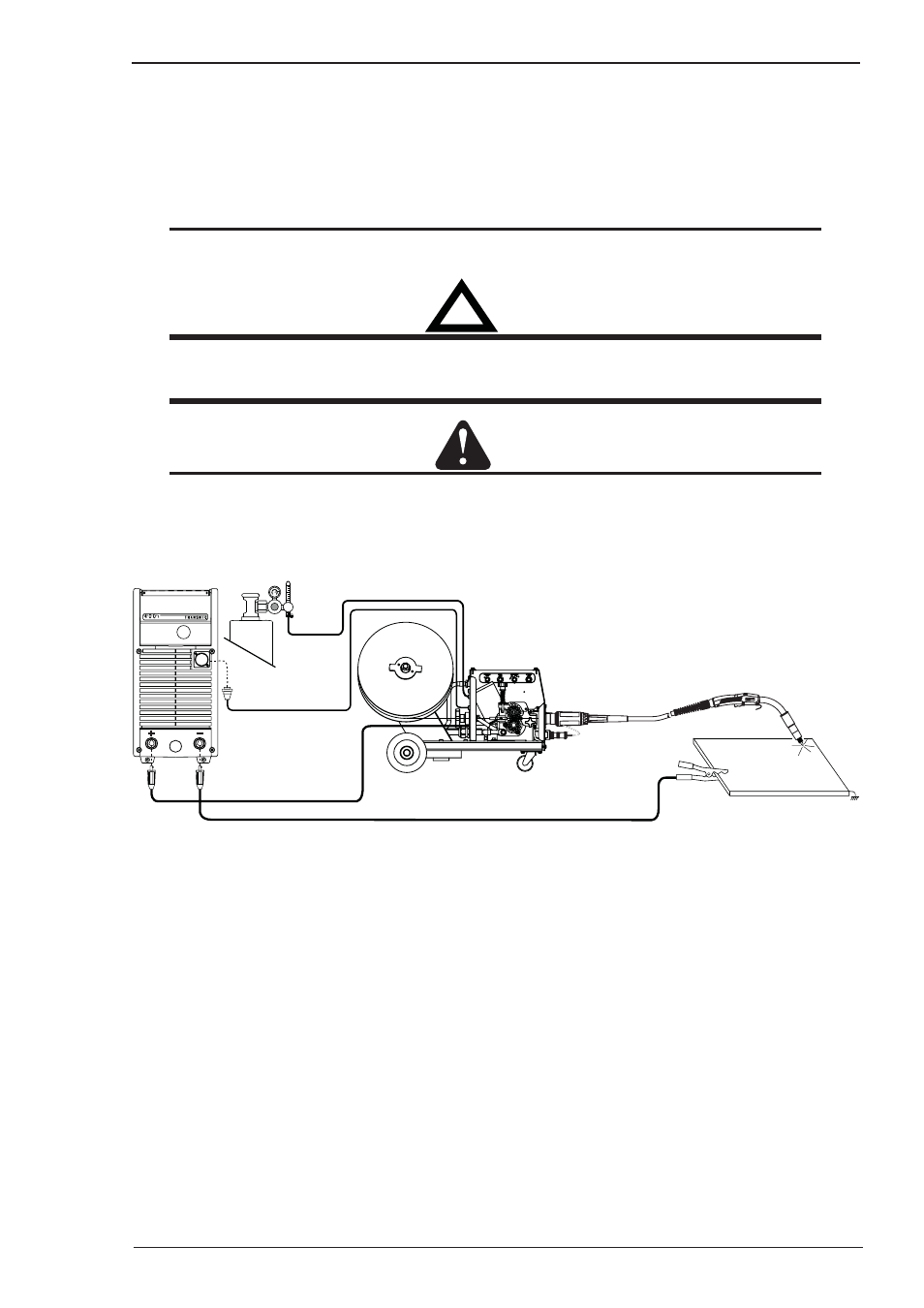

Refer to Figure 4-5 for a typical MIG welding configuration and connect your equipment accordingly.

NOTE

Consult the wire feeder manual on how to adjust the wire feed speed and connect the MIG gun.

!

WARNING

Before connecting the work clamp to the work and inserting the electrode in the electrode holder

make sure the primary power supply is switched off.

CAUTION

Remove any packaging material prior to use. Do not block the air vents at the front or rear or sides

of the welding power source.

14-Pin Control Cable

Constant Speed

Wire Feeder

MIG Gun

Electrode Lead *

Gas

Work Lead *

Workpiece

Transmig 400 i

* These leads may need to be reversed when using flux core welding wire.

Contact the welding wire manufacturer for details.

Figure 4-5: Transmig 400 i GMAW (MIG) Set-up