Transmig 400 i – Tweco 400i Transmig User Manual

Page 23

TRANSMIG 400 i

July 18, 2008

4-1

SECTION 4:

OPERATION

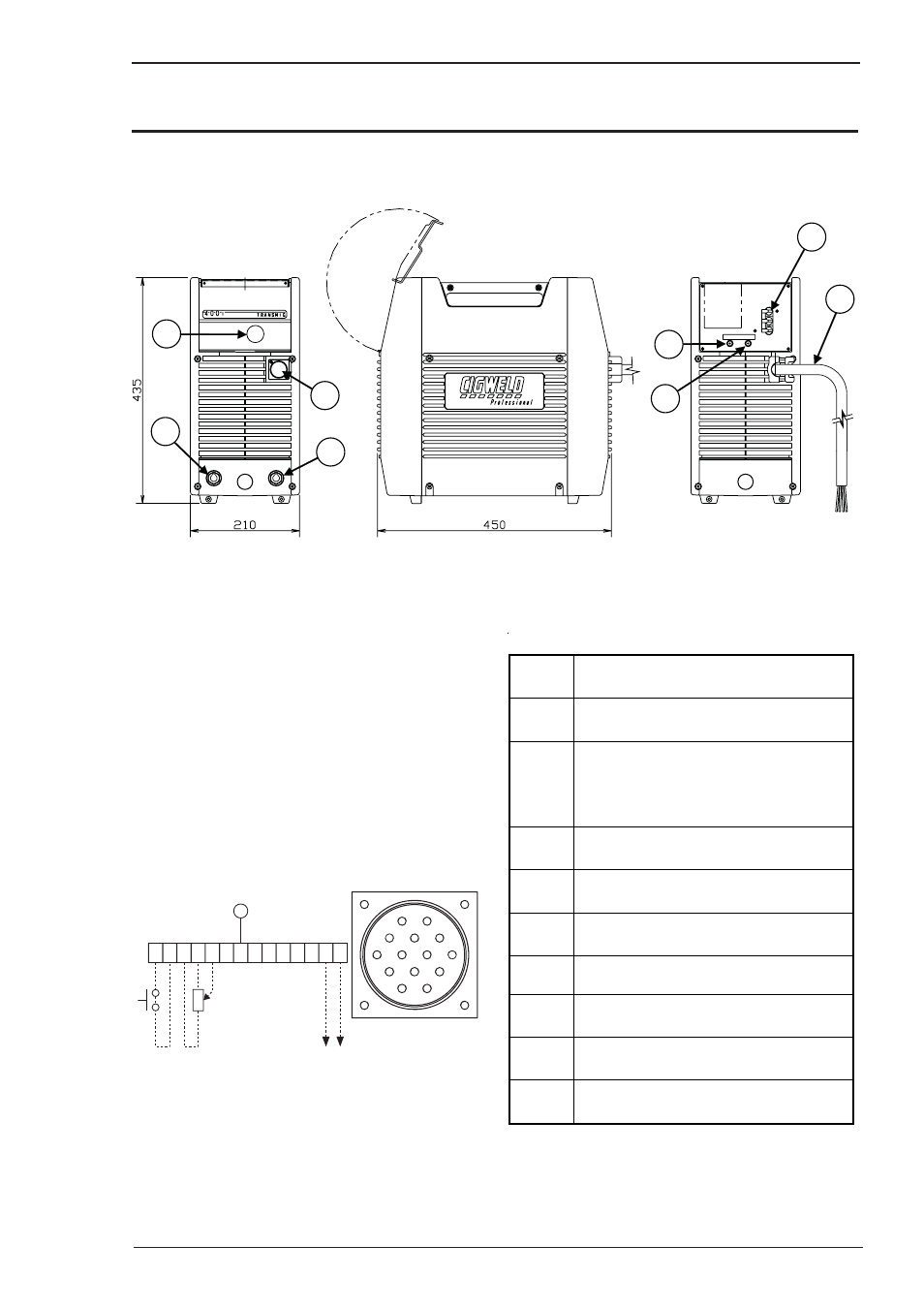

4.01 Transmig 400 i Controls

Art A-08355_AB

7

8

6

5

2

1

3

4

Figure 4-1: Transmig 400 i Power Source

1. Control Knob:

This control sets the selected weld

parameter, rotating it clockwise increases the

parameter that is indicated on the digital meter.

Pushing the knob inward displays the actual welding

voltage.

2 . Remote Control Socket:

The 14 pin Remote

Control Socket is used to connect remote current

control devices to the welding Power Source. To

make connections, align keyway, insert plug, and

r

otate threaded collar fully clockwise.

A

J

B

K

I

C L

N H

D M G

F

E

A B C

E

Front view of 14

Socket Receptacle

5k ohms

Art # A-07653_AB

D E F

H I J K L M N

G

Figure 4-2: 14-Pin Socket Receptacle

Socket

Pin

Function

A

Torch Switch Input (24V) to (connect

pins A & B to turn on welding current).

Torch Switch Input (0V) to energize

weld

B

current (connect pins A & B to turn on

welding current).

C

5k ohm (maximum) connection to 5k

ohm remote control potentiometer.

D

Zero ohm (minimum) connection to 5k

ohm remote control potentiometer.

E

Wiper arm connection to 5k ohm

r

emote control potentiometer.

G

Mains Earth.

F,H,I,J,

K,L

Not Used.

M

OK to move current detect signal for

r

obotics applications.

N

OK to move current detect signal for

r

obotics applications.

Table 4-1: Socket Pin Functions