Tweco 350 4R Wirefeeder User Manual

Page 51

7-7

Manual 0-5182

service weldskill 250, 350

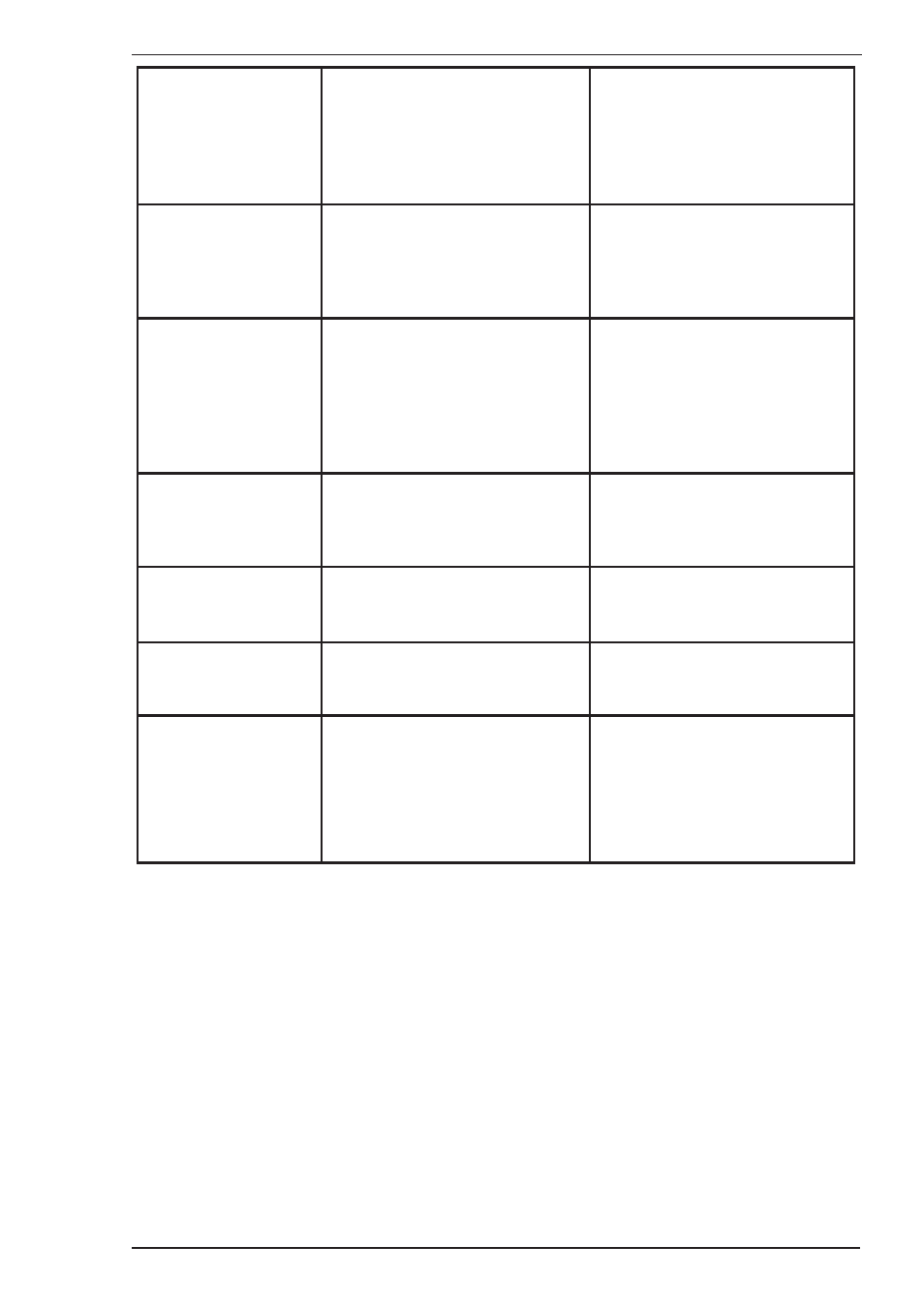

Service

5 Wire feeds when

the torch trigger

switch is depressed

but arc cannot be

established.

A

B

Mig torch polarity lead is not

connected into a welding output

terminal.

Poor or no work lead contact.

A

B

Connect the MIG torch polarity

lead to either the positive welding

output terminal or negative output

terminal as required.

Clean work clamp area and ensure

good electrical contact.

6 Inconsistent wire feed A

B

C

D

Worn or dirty contact tip

Worn feed roll.

Excessive back tension from wire

reel hub.

Worn, kinked or dirty conduit liner

A

B

C

D

Replace if necessary.

Replace if necessary.

Reduce brake tension on spool

hub

Clean or replace conduit liner

7 No gas flow

A

B

C

D

Gas hose is cut.

Gas passage contains impurities.

Gas regulator turned off.

Empty Cylinder

A

B

C

D

Replace or repair.

Disconnect gas hose from the rear

of Power Source or wirefeeder

then raise gas pressure and blow

out impurities.

Turn on.

Replace cylinder.

8 Gas flow continues

after the torch trigger

switch has been

released.

Gas valve has jammed open due

to impurities in the gas or the gas

line.

Have an Accredited CIGWELD

Service Provider repair or replace

gas valve.

9 Wire does not feed

when torch trigger

depressed

A

B

Faulty trigger switch / lead

Circuit breaker tripped

A

B

Repair or replace Torch / trigger

lead

Reset Circuit Breaker(s)

10 Wire continues to

feed when torch

trigger released

A

B

Power Source in 4T (LATCH) mode

Torch trigger leads shorted

A

B

Change to 2T (NORMAL) mode

Repair or replace Torch / trigger

lead

11 Wire feeds when the

torch trigger switch is

depressed but arc can

not be established

and OVERHEAT led is

illuminated

Power Source Overtemperature

Protection circuit has operated

Cease welding and allow Power

Source to Cool for 10 minutes.

Overheat led will extinguish when

the Power Source has cooled

sufficiently.