Tweco 350 4R Wirefeeder User Manual

Page 36

5-4

Manual 0-5182

weldskill 250, 350 set up

Setup

trode wire manufacturer. (Power Source Torch Polarity Lead not required to be connected when using

wirefeeder)

B. Connect the control cable from the Wirefeeder to the control socket on the Power Source.

C. Fit the gas regulator and flowmeter to the gas cylinder then connect the gas hose from the rear of the

Wirefeeder to the Flowmeter outlet.

D. Dual groove feed rollers are supplied as standard. They can accommodate 0.9/1.2mm diameter hard

wires. Select the roller required with the chosen wire size marking facing outwards.

GROOVE “B”

GROOVE “A”

GROOVE “A” SIZE

GROOVE “B” SIZE

Art # A-08739

E. Fit the electrode wire spool to the wirefeeder wire reel hub. (Note that there is an adaptor supplied when

using 200mm diameter wire spools). Ensure that the drive dog-pin engages the mating hole in the wire

spool. Push the spool securing clip into place to retain the wire spool securely. The electrode wire should

feed from the bottom of the spool.

F. MIG Torch, EURO MIG Torch Connection

Fit the MIG Torch to the Wirefeeder by pushing the torch connector into the brass torch adaptor and

screwing the plastic torch nut clockwise to secure the torch to the torch adaptor. Remove the contact tip

from the torch handset.

Art # A-09924_AC

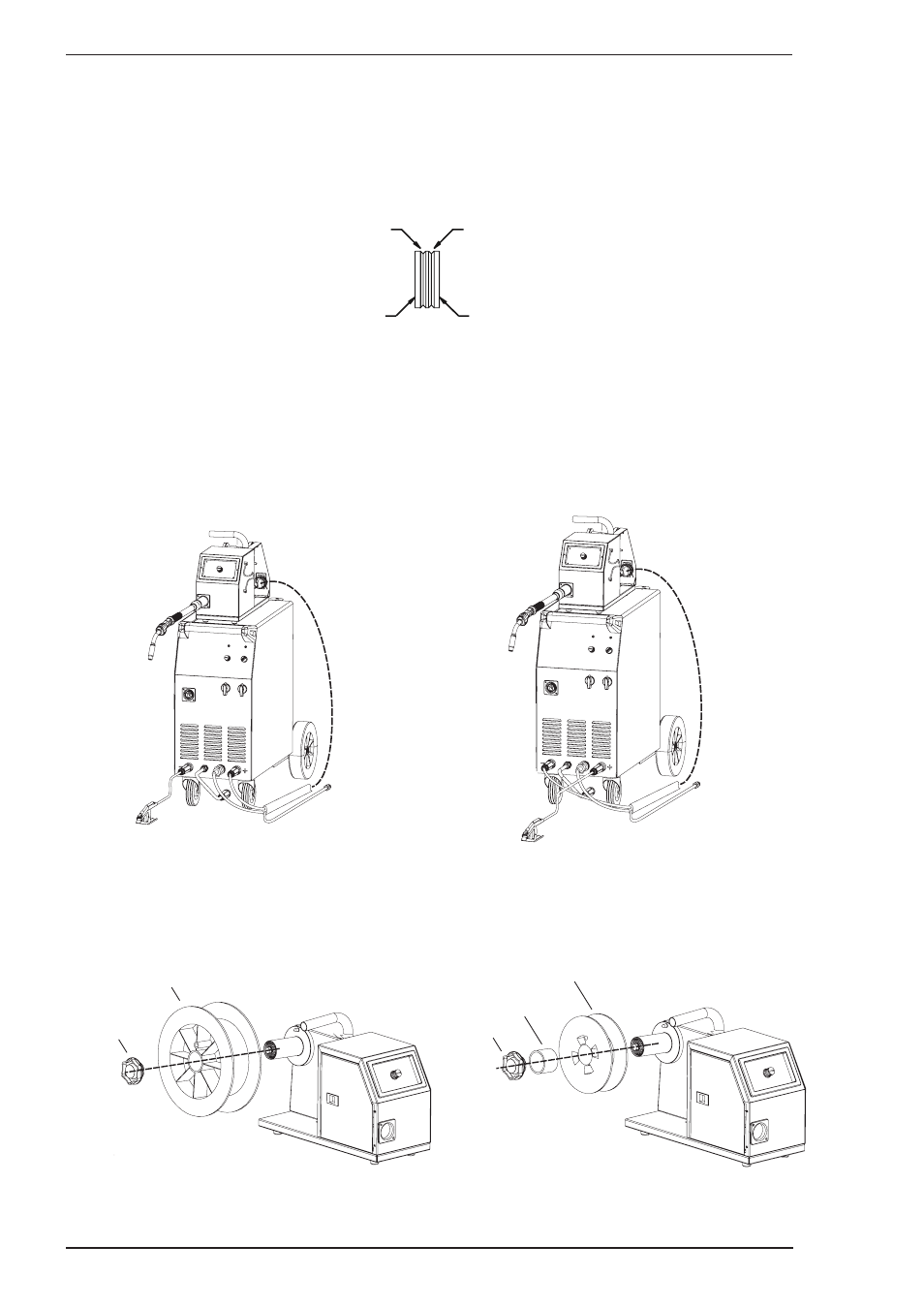

Setup for MIG (GMAW) Welding

with Gasless MIG Wire

Setup for MIG (GMAW) Welding

with Gas Shielded MIG Wire

300mm Wire spool installation

200mm Wire spool installation

TO SHIELDING GAS

REGULATOR

TO SHIELDING GAS

REGULATOR

200mm Diameter

Wire Spool

300mm Diameter

Wire Spool

Spool Hub Nut

200mm Diameter

Wire Spool Adaptor

Spool Hub Nut

Figure 5-2 WeldSkill 250 & 350 WF Setup and WF Spool Hub