Tweco 350 4R Wirefeeder User Manual

Page 32

4-8

Manual 0-5182

weldskill 250, 350 operation

Operation

5. To protect sensitive down-stream equipment

a separate safety device may be necessary if

the regulator is not fitted with a pressure relief

device.

Operation

With the regulator connected to cylinder or pipeline,

and the adjustment screw/knob fully disengaged,

pressurize as follows:

1. Stand to one side of regulator and slowly open

the cylinder valve. If opened quickly, a sudden

pressure surge may damage internal regulator

parts.

2. With valves on downstream equipment closed,

adjust regulator to approximate working pres-

sure. It is recommended that testing for leaks

at the regulator connection points be carried

out using a suitable leak detection solution or

soapy water.

3. Purge air or other unwanted welding grade

shielding gas from equipment connected to

the regulator by individually opening then

closing the equipment control valves. Com-

plete purging may take up to ten seconds or

more, depending upon the length and size of

the hose being purged.

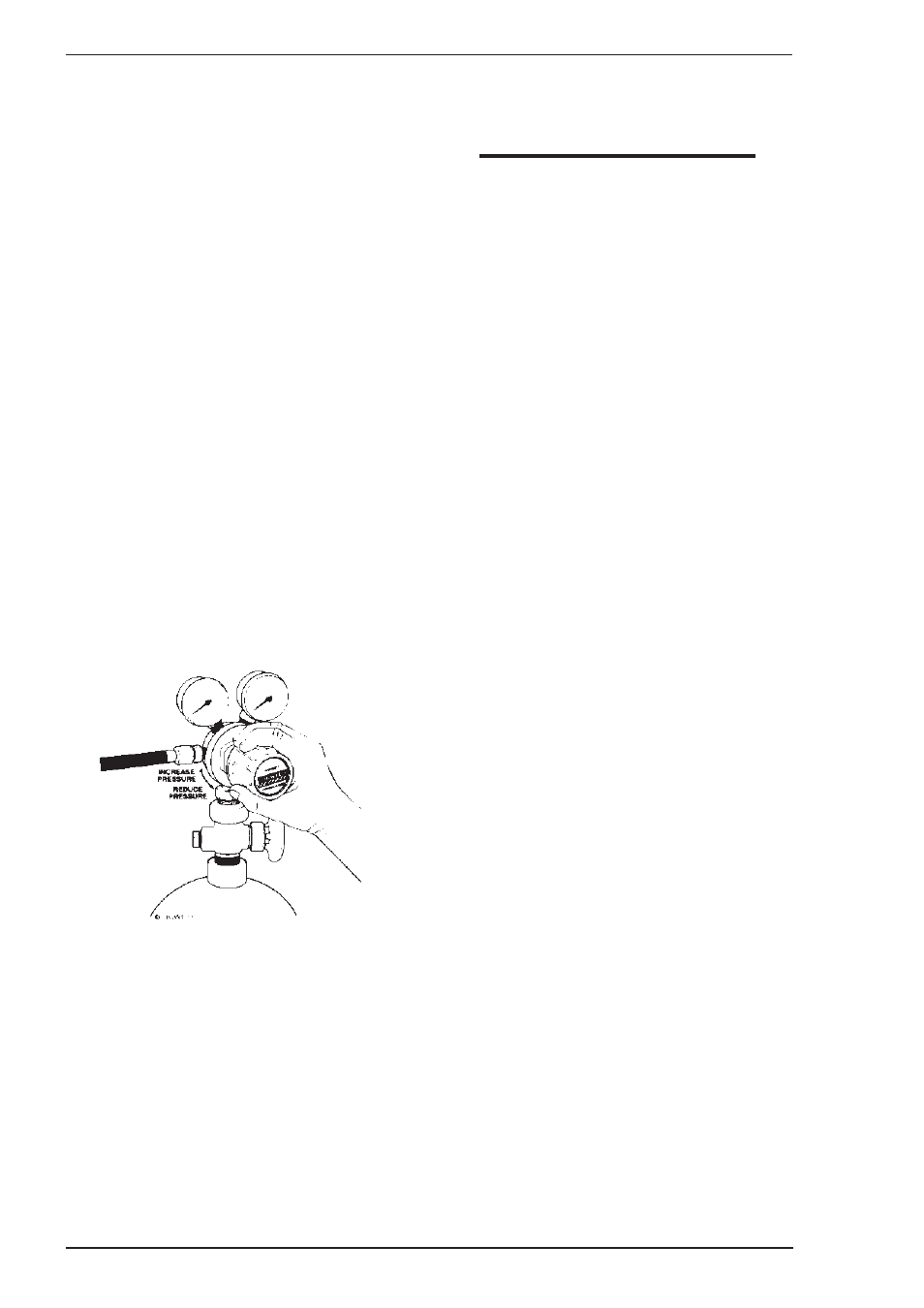

Adjusting Flow Rate

Art: A-05088_AB

Figure 4-5 Adjust Flow Rate

With the regulator ready for operation, adjust working

flow rate as follows:

1. Slowly turn adjusting screw/knob in (clock-

wise) direction until the outlet gauge indicates

the required flow rate.

NOTE

It may be necessary to re-check the shield-

ing gas regulator flow rate following the

first weld sequence due to back pressure

present within shielding gas hose as-

sembly.

2. To reduce flow rate, allow the welding grade

shielding gas to discharge from regulator by

opening the downstream valve. Bleed weld-

ing grade shielding gas into a well ventilated

area and away from any ignition source. Turn

adjusting screw counterclockwise, until the

required flow rate is indicated on the gauge.

Close downstream valve.

Shutdown

Close cylinder valve whenever the regulator is not in

use. To shut down for extended periods (more than

30 minutes).

1. Close cylinder or upstream valve tightly.

2. Open downstream equipment valves to drain

the lines. Bleed gas into a well ventilated area

and away from any ignition source.

3. After gas is drained completely, disengage

adjusting screw and close downstream equip-

ment valves.

4. Before transporting cylinders that are not se-

cured on a cart designed for such purposes,

remove regulators.