04 grounding, Installation excel arc 6045 – Tweco 6045 Excel Arc User Manual

Page 23

INSTALLATION EXCEL

ARC

6045

August 26, 2011

3-3

Manual 0-5213

3.04 Grounding

The frame of this welding machine should be grounded for

personnel safety, and to assure operation of the overcurrent

protection. The grounding method, and the equipment

grounding conductor size and type shall conform to local

and national codes. For the National Electrical Code, the

equipment grounding conductor shall be green, green with

a yellow stripe, or bare. If fl exible power cable is used, use

a cable assembly which includes the equipment grounding

conductor. If metallic armored cable or conduit is used, the

metal sheathing or conduit must be effectively grounded

per local and national codes.

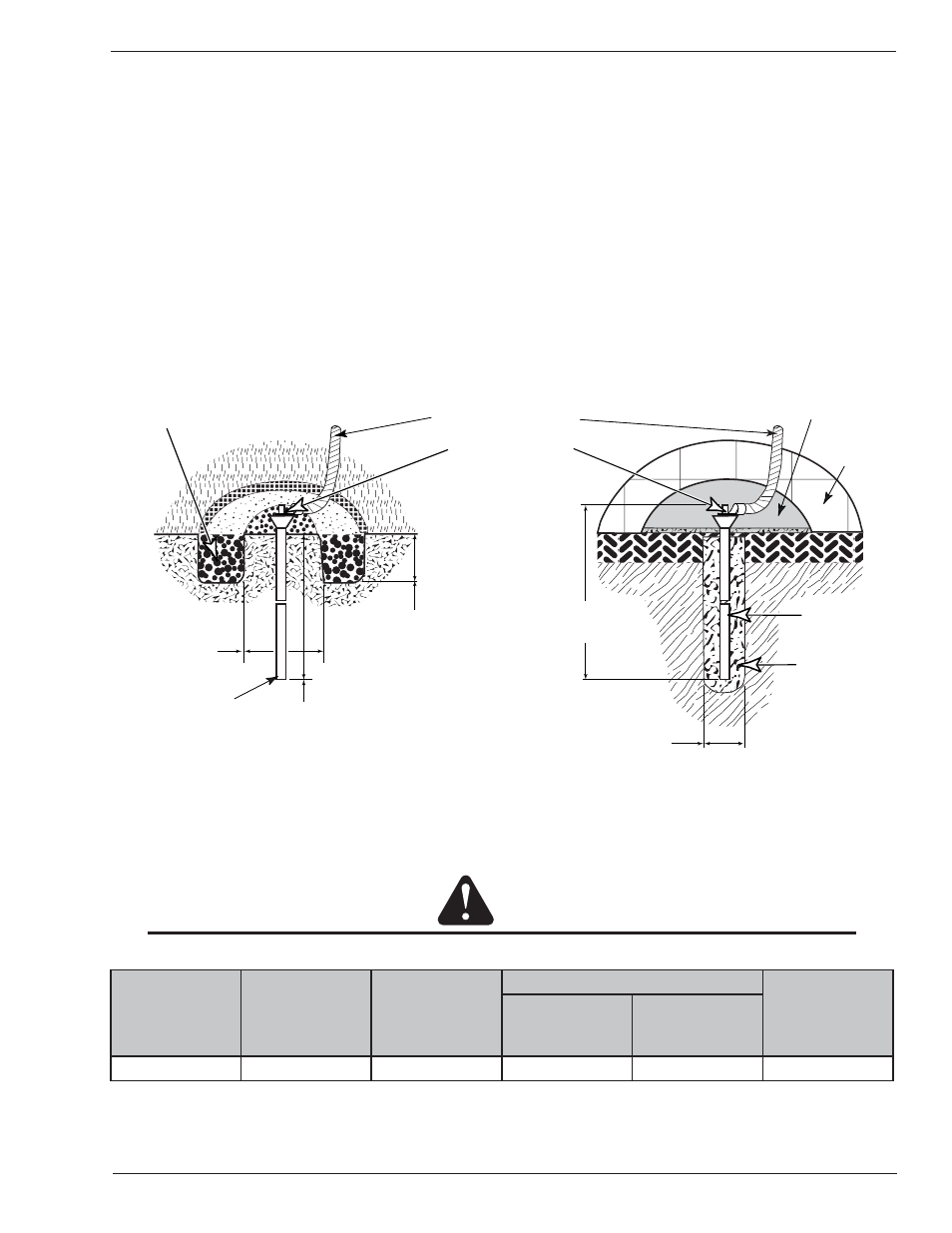

Not less than

24.4 cm (8 Ft.)

9.1-13.6 kg (20-30 lbs.) Soil Treating Material

(copper sulphate, magnesium sulphate or rock salt)

placed in circular trench and covered

with earth.

Grounding Conductor

Fasten Grounding

Conductor to the

rod with an

approved

ground clamp.

Approx. 305 mm (1 Ft.)

457 mm

(18 inches)

Approx.

Ground Rod

Removable Cover

Floor

Not less than 24.4 cm (8 Ft.)

152 mm (6 Inches) Approx.

Ground

Rod

Soil

Treating

Material

Art # A-05234_AB

Figure 3-2: Grounding Diagram

The equipment grounding conductor size is listed in "Table 3-3: Recommended Wire and Fuse Size" as a guide, if

no local or national code is applicable. Attach the equipment grounding conductor to the stud provided on the yoke.

Determine that the ground wire size is adequate before the machine is operated.

CAUTION

Be sure to replace all covers to assure adequate internal ventilation and prevent component failure.

LINE VOLTS

RATED LOAD

AMPS

APPROX. LINE

FUSE SIZE

COPPER LINE WIRE SIZE*

COPPER

GROUNDING

CONDUCTOR

MIN. SIZE

IN CONDUIT

FLEXIBLE CABLE

460

38

60

No. 8

No. 8

No. 8

*Conductor size shall be modifi ed as required for line voltage drop and ambient temperature. Sizes listed for conduit installation are based on 90° C conductor

insulation, designated as FEP, FEPB, RHH, and THHN.

Table 3-3: Recommended Wire and Fuse Size

Rubber-tire mounted equipment shall be grounded to

conform to local and national codes. The grounding

assists in providing protection against line voltage

electrical shock and static shock. The grounding serves

to discharge the static electric charge which tends to

build up on rubber-tire mounted equipment. This static

charge can cause painful shock and lead to the erroneous

conclusion that an electrical fault exists in the equipment.

If a system ground is not available, consult the electrical

code enforcement body for instructions. The welding

machine should be connected to an adequate driven

ground rod, or to a water pipe that enters the ground not

more than 30 meters (10 feet) from the machine.