Arcmaster, 160ts – Tweco 160 TS Arcmaster User Manual

Page 43

ARCMASTER

®

160TS

March 31, 2006

9-3

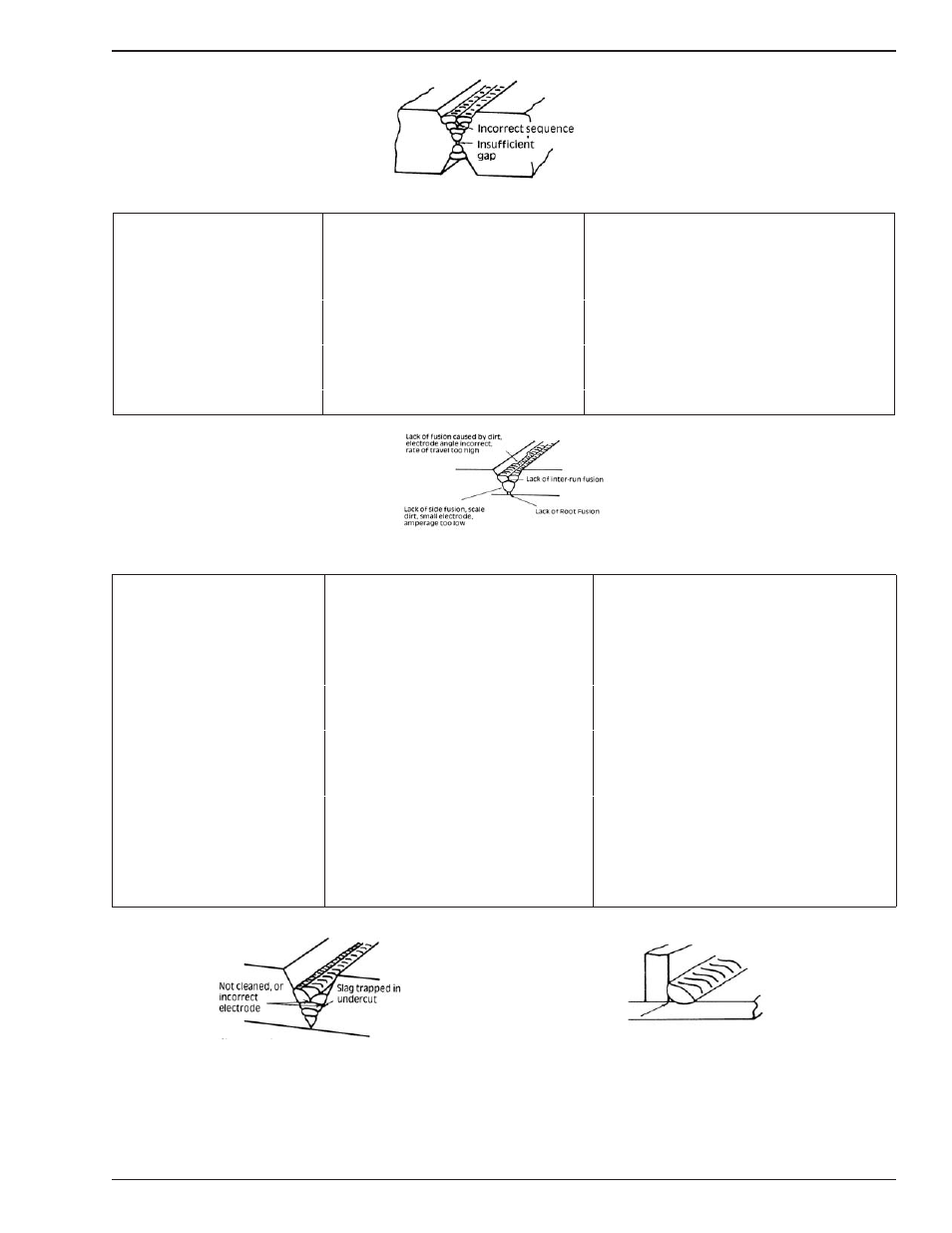

Figure 8 – Example of insuffi cient gap or incorrect sequence

4. Portions of the weld run

do not fuse to the surface

of the metal or edge of the

joint.

A.

B.

Small electrodes used on heavy

cold plate.

Welding current is too low.

A

.

B.

Use larger electrodes and pre-heat the

plate.

Increase welding current

C. Wrong electrode angle.

C. Adjust angle so the welding arc is directed

more into the base metal

D. Travel speed of electrode is too

high.

D. Reduce travel speed of electrode

E. Scale or dirt on joint surface.

E. Clean surface before welding.

Figure 9 – Example of lack of fusion

5. Non-metallic parti cles are

trapped in the weld metal

(slag inclusion).

A. Non-metallic particles may be trapped

in undercut from previous run.

A. If bad undercut is present, clean slag

out and cover with a run from a smaller

diameter electrode.

B. Joint preparation too restricted.

B. Allow for adequate penetration and room

for cleaning out the slag.

C. Irregular deposits allow slag to be

trapped.

C. If very bad, chip or grind out irregularities.

D. Lack of penetration with slag trapped

beneath weld bead.

D. Use smaller electrode with suffi cient current

to give adequate penetration. Use suitable

tools to remove all slag from corners.

E. Rust or mill scale is preventing full

fusion.

E. Clean joint before welding.

F.

Wrong electrode for position in which

welding is done.

F.

Use electrodes designed for position in

which welding is done, otherwise proper

control of slag is diffi cult.

Figure 10 – Examples of slag inclusion