Arcmaster, 160ts, 02 hf tig & lift tig welding – Tweco 160 TS Arcmaster User Manual

Page 32

ARCMASTER

®

160TS

March 31, 2006

5-2

5.02 HF TIG & Lift TIG Welding

• Connect work lead to positive terminal

• Connect TIG torch to negative terminal

• Switch machine on

• Set WELD current.

• Connect remote control device. A remote control device

is required for use during LIFT TIG and HF TIG operation.

See section 3.01, section 2 “Remote Control Socket”,

for complete details of the remote device.

Use the Scroll Buttons to move to the parameter to be set.

The LED will show which function is being adjusted on the

weld sequence graph. Use the control knob to adjust each

parameter.

• Set PRE-FLOW time

• Set HOT START current

• Set POST-FLOW time

• Set WELD current

• Set POST-FLOW time

Slope Mode Parameters if required

• Set INITIAL CUR current

• Set UP SLOPE time

• Set (WELD) PEAK CUR current

• Set BASE current

• Set DOWN SLOPE time

• Set CRATER CUR current

Pulse Mode parameters if required

• Set PULSE WIDTH % for PEAK CURRENT

• Set PEAK CURRENT

• Set PULSE FREQ

Commence welding

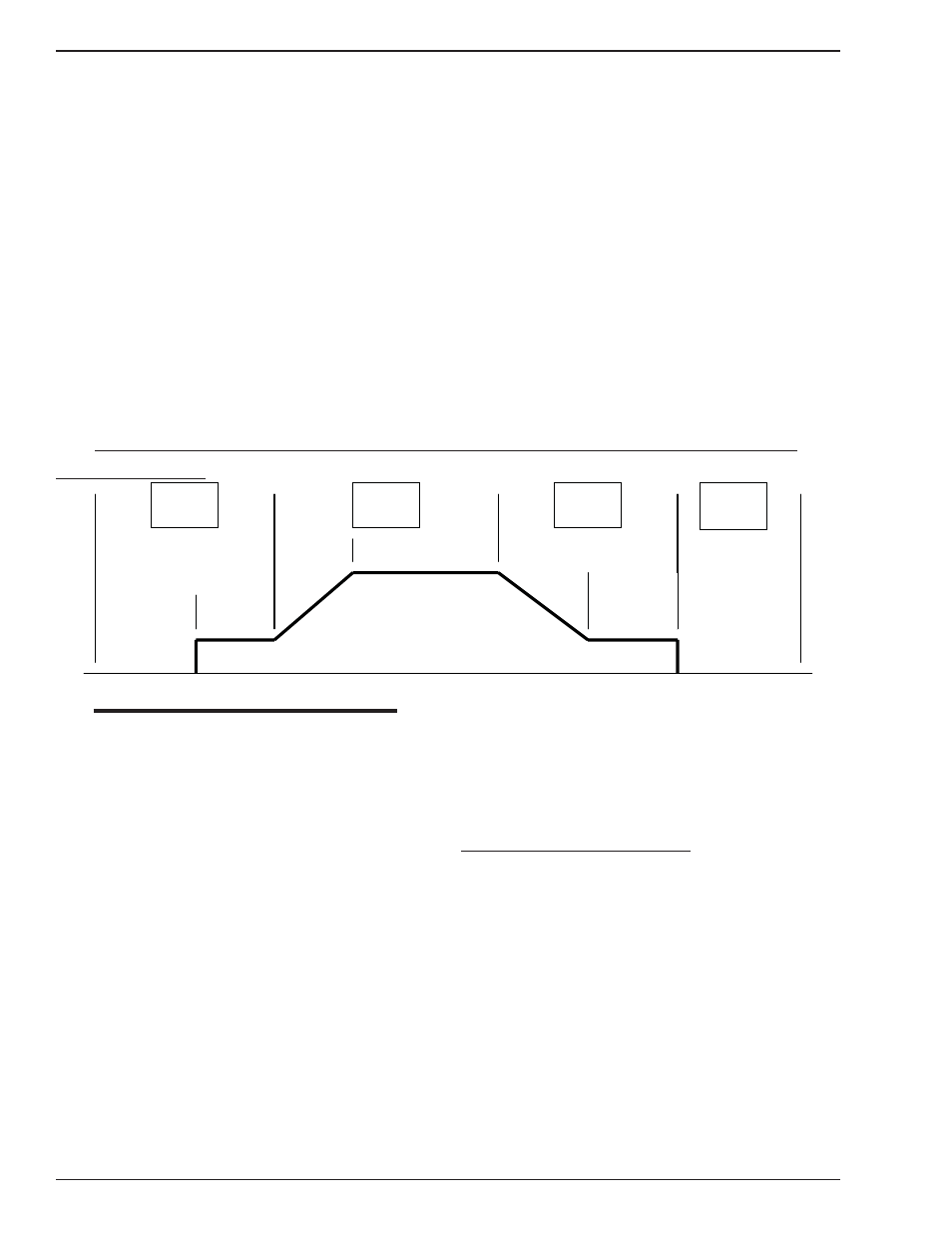

Slope Mode Sequence

Weld Current

Down

Slope

Up

Slope

Initial

Current

Switch

Closed

Switch

O pen

Switch

Closed

Switch

O pen

Preflow

Final

Current

Postflow

NOTE

Slope function operates with a Remote ON/OFF

device only.

1) To start Slope sequence Close remote switch contacts.

Once the welding arc is established the Power Source

will maintain initial current setting as long as the remote

switch contacts are closed.

a) In the HF TIG mode, after Pre-fl ow time High Frequency

is present at the torch. When the torch is positioned

close to the work the welding current will transfer to

the work and establish the arc at the initial current

setting.

b) In the Lift TIG mode, after pre-fl ow time Lift Start

current is present at the torch. When the electrode

is touched to the work and lifted off, the welding arc

is established at the initial current setting.

2) Open Remote Switch – current increases to weld current.

Once welding arc has reached weld current the power

source will maintain weld current as long as the remote

switch contacts are open.

3) Close Remote Switch – Welding current decreases to fi nal

current setting. Once fi nal welding current is reached the

power source will maintain fi nal current setting as long

as the remote switch contacts are closed.

4) Open Remote Switch – Welding arc stops and post fl ow

begins.

Slope Mode with repeat sequence

The repeat function is operated during the down slope cycle

of the Slope Sequence and is active through the down slope

period only. During the down slope period by opening the

Remote Switch contacts the current will increase back to weld

current. Within the Down Slope period the repeat function can

operated as many times as desired. To continue slope cycle

and end slope sequence close remote switch contacts and

allow weld current to reach fi nal current setting. Once fi nal

current setting is reached opening the Remote Switch again

will turn off the welding arc and post fl ow begins.