Arcmaster, 160ts, 02 stick welding problems – Tweco 160 TS Arcmaster User Manual

Page 42

ARCMASTER

®

160TS

March 31, 2006

9-2

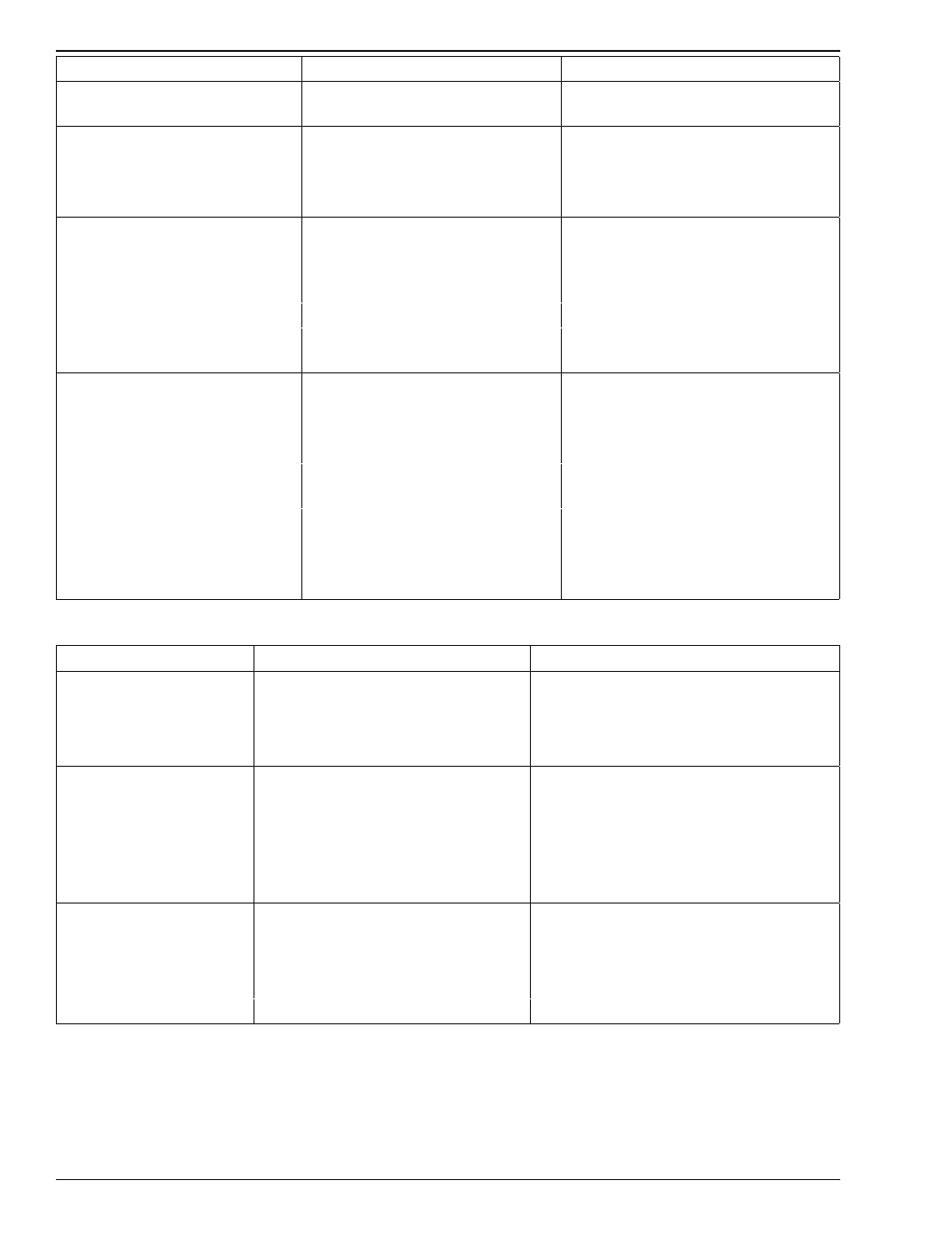

Description

Possible Cause

Remedy

9.

Poor weld fi nish.

Inadequate shielding gas.

Increase gas fl ow or check gas line for

gas fl ow problems.

10. Arc fl utters during TIG welding.

A. Tungsten electrode is too large for

the welding current.

A.

Select the right size electrode. Refer

to Basic TIG Welding guide.

B. Absence of oxides in the weld

pool.

B.

Refer Basic TIG Welding Guide for ways

to reduce arc fl utter.

11. Welding arc can not be

established.

A. Work clamp is not connected to

the work piece or the work/torch

leads are not connected to the right

welding terminals.

A.

Connect the work clamp to the work

piece or connect the work/torch leads

to the right welding terminals.

B. Torch lead is disconnected.

B.

Connect it to the ‘−‘ terminal.

C. Gas fl ow incorrectly set, cylinder

empty or the torch valve is off.

C.

Select the right flow rate, change

cylinders or turn torch valve on.

12. Arc start is not smooth.

A. Tungsten electrode is too large for

the welding current.

A.

Select the right size electrode. Refer

to Basic TIG Welding Guide.

B. The wrong electrode is being used

for the welding job

B.

Select the right electrode type. Refer

to Basic TIG Welding Guide

C. Gas fl ow rate is too high.

C.

Select the correct rate for the welding job.

Refer to Basic TIG Welding Guide.

D. Incorrect shielding gas is being

used.

D. Select the right shielding gas. Refer to

Basic TIG Welding Guide.

E. Poor work clamp connection to

work piece.

E.

Improve connection to work piece.

9.02 Stick Welding Problems

Description

Possible Cause

Remedy

1. Gas pockets or voids in

weld metal (Porosity).

A.

B.

C.

Electrodes are damp.

Welding current is too high.

Surface impurities such as oil, grease,

paint, etc.

A.

B.

C.

Dry electrodes before use.

Reduce welding current.

Clean joint before welding.

2. Crack occurring in

weld metal soon

after solidifi cation

commences

A.

B.

C.

Rigidity of joint.

Insuffi cient throat thickness.

Cooling rate is too high.

A .

B .

C.

Redesign to relieve weld joint of severe

stresses or use crack resistance

electrodes.

Travel slightly slower to allow greater build

up in throat.

Preheat plate and cool slowly.

3. A gap is left by failure of

the weld metal to fi ll the

root of the weld.

A.

B.

C.

Welding current is too low.

Electrode too large for joint.

Insuffi cient gap.

A.

B .

C.

Increase welding current

Use smaller diameter

electrode.

Allow wider gap.

D. Incorrect sequence.

D. Use correct build-up sequence.