Arcmaster, 160ts – Tweco 160 TS Arcmaster User Manual

Page 24

ARCMASTER

®

160TS

March 31, 2006

3-2

3. Positive Terminal

Welding current fl ows from the Power Source via heavy

duty Dinse type terminal. It is essential, however, that

the male plug is inserted and turned securely to achieve

a sound electrical connection.

4. Negative Terminal

Welding current fl ows from the Power Source via heavy

duty Dinse type terminal. It is essential, however, that

the male plug is inserted and turned securely to achieve

a sound electrical connection.

CAUTION

Loose welding terminal connections can cause

overheating and result in the male plug being

fused in the bayonet terminal.

5. Gas Outlet

The Gas Outlet is a BSP 3/8” female gas fi tting.

6. ON/OFF Switch

This switch connects the Primary supply voltage to the

inverter when in the ON position. This enables the Power

Supply.

!

WARNING

When the welder is connected to the Primary

supply voltage, the internal electrical components

maybe at 240V potential with respect to earth.

7. Input Cable

The input cable connects the Primary supply voltage to

the equipment.

8. Gas Inlet

The Gas Inlet is a BSP 3/8” female gas fi tting.

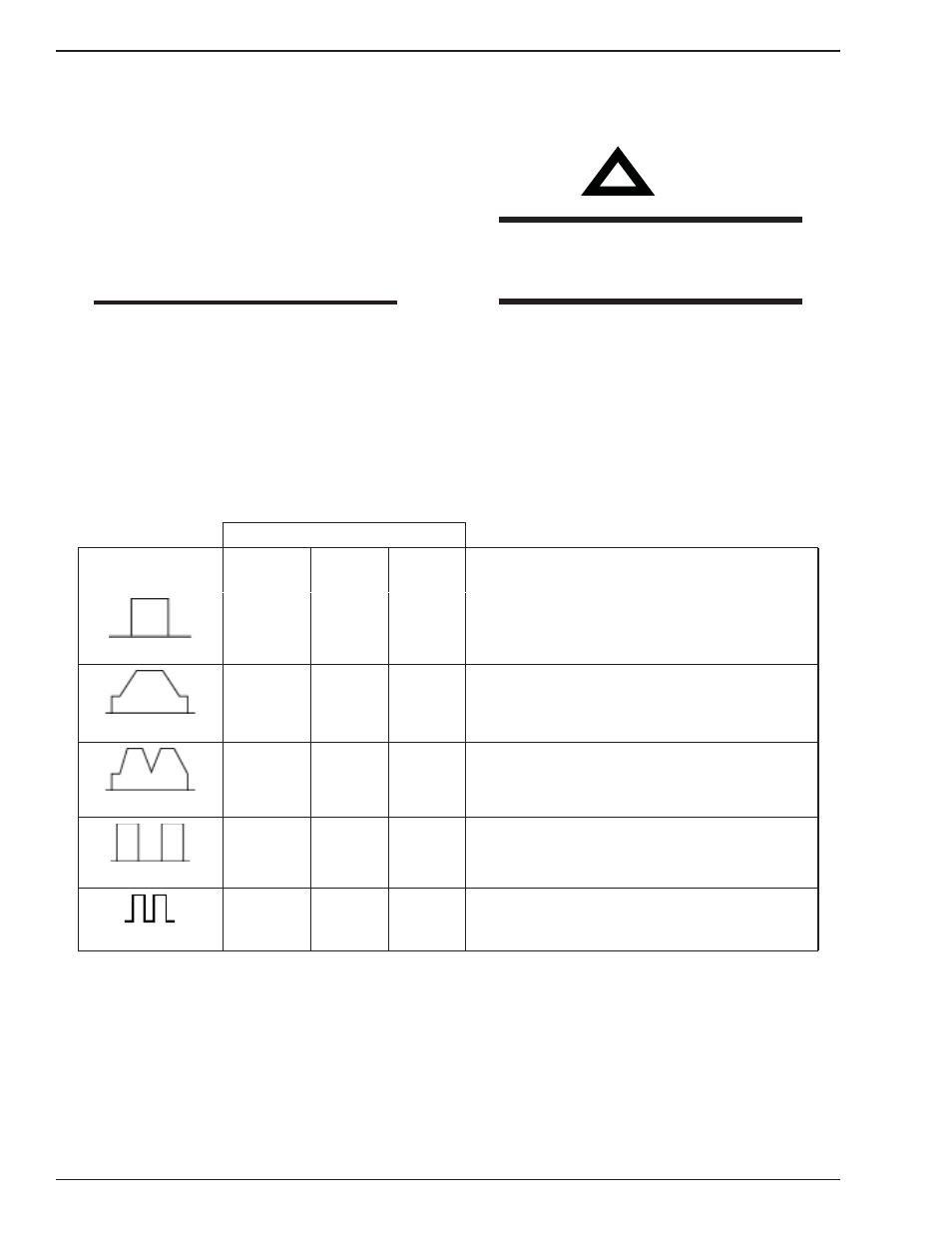

3.02 Weld Process selection for ArcMaster 160TS

Weld Mode

Weld Process

Selection

STICK

HF

TIG

LIFT TIG

Description

STD

Yes

Yes

Yes

2T operation in TIG Modes using remote devices to

control contactor & current

SLOPE

No

Yes

Yes

4T operation in TIG Modes with crater fi ll using a remote

contactor device to control sequence.

REPEAT

No

Yes

Yes

4T operation in TIG Modes with repeat operation and

crater fi ll using a remote contactor device.

SPOT

No

Yes

No

2T operation spot welding in HF TIG using a remote

contactor device.

PULSE ON/OFF

No

Yes

Yes

Pulse operation in TIG Modes

Table 3 – Weld Process selection verses Weld Mode for ArcMaster 160TS