Arcmaster, 160ts – Tweco 160 TS Arcmaster User Manual

Page 20

ARCMASTER

®

160TS

March 31, 2006

2-6

• Input Power

Each unit incorporates an INRUSH circuit and input voltage sensing circuit. When the MAIN CIRCUIT SWITCH is turned on, the

inrush circuit provides a pre-charging of the input capacitors. SCR’s in the Power Control Assembly (PCA) will turn on after the

input capacitors have charged to full operating voltage (after approximately 5 seconds).

NOTE

Note the available input power. Damage to the PCA could occur if 460VAC or higher is applied.

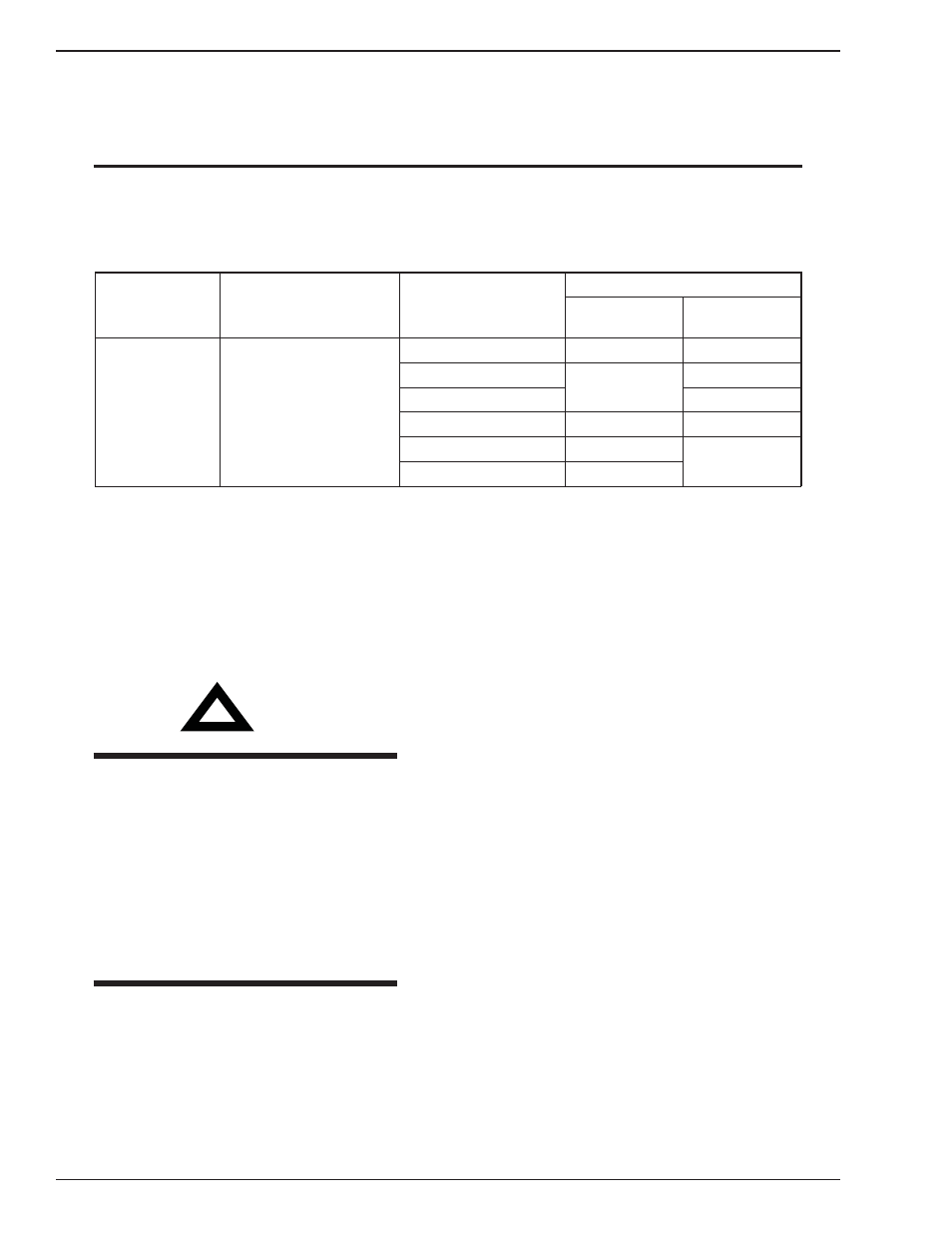

The following 115/230V Primary Current recommendations are required to obtain the maximum welding current and duty

cycle from this welding equipment:

Model

Primary Supply Lead Size

(Factory Fitted)

Minimum Primary

Current Circuit Size

(Vin/Amps)

Current & Duty Cycle

TIG

STICK

ArcMaster 160TS

12/3 AWG minimum

115/22

85A @ 100%

-

208/28

160A @ 35%

-

230/25

-

115/39

-

85A @ 100%

208/44

-

160A @ 35%

230/39

-

Table 2 – 115/230V Primary Current Circuit sizes to achieve maximum current

• High Frequency Introduction

The importance of correct installation of high frequency

welding equipment cannot be over-emphasized. Interference

due to high frequency initiated or stabilized arc is almost

invariably traced to improper installation. The following

information is intended as a guide for personnel installing

high frequency welding machines.

!

Warning

Explosives

The high frequency section of this machine has

an output similar to a radio transmitter. The

machine should NOT be used in the vicinity

of blasting operations due to the danger of

premature fi ring.

Computers

It is also possible that operation close to computer

installations may cause computer malfunction.

• High Frequency Interference

Interference may be transmitted by a high frequency initiated

or stabilized arc welding machine in the following ways:

Direct Radiation

Radiation from the machine can occur if the case is

metal and is not properly grounded. It can occur through

apertures such as open access panels. The shielding of

the high frequency unit in the Power Source will prevent

direct radiation if the equipment is properly grounded.

Transmission via the Supply Lead

Without adequate shielding and fi ltering, high frequency

energy may be fed to the wiring within the installation

(mains) by direct coupling. The energy is then transmitted

by both radiation and conduction. Adequate shielding and

fi ltering is provided in the Power Source.

Radiation from Welding Leads

Radiated interference from welding leads, although

pronounced in the vicinity of the leads, diminishes

rapidly with distance. Keeping leads as short as possible

will minimize this type of interference. Looping and

suspending of leads should be avoided where possible.

Re-radiation from Unearthed Metallic Objects

A major factor contributing to interference is re-radiation

from unearthed metallic objects close to the welding

leads. Effective grounding of such objects will prevent

re-radiation in most cases.