Fabricator 181i – Tweco 181i Fabricator User Manual

Page 81

Fabricator 181i

Manual 0-5191

4-23

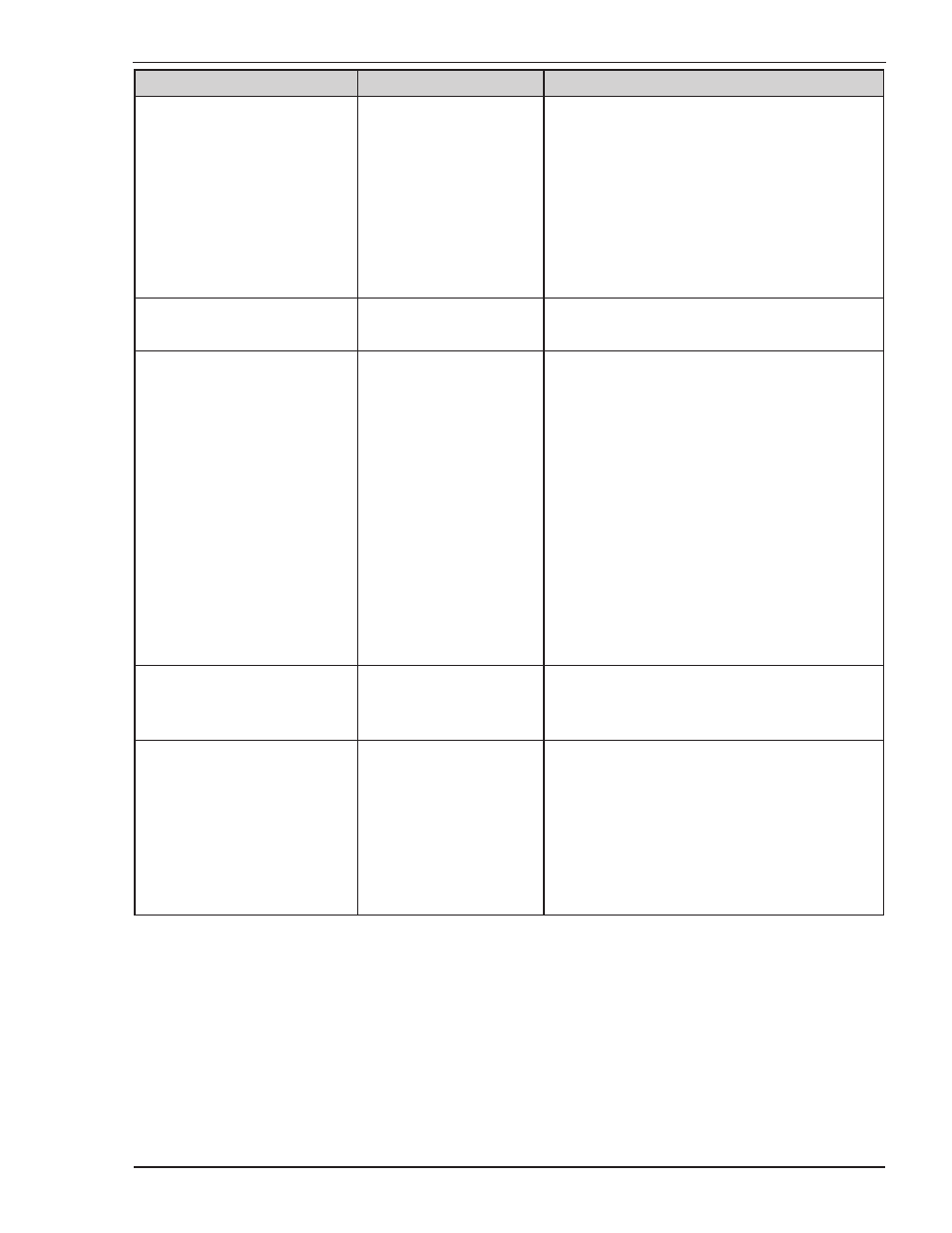

BASIC WELDING GUIDE

FAULT

CAUSE

REMEDY

7 Dirty weld pool

A Electrode contaminated

by contact with work

piece or filler rod mate-

rial.

A Clean the electrode by grinding off the con-

taminates.

B Work piece surface has

foreign material on it.

B Clean surface.

C Gas contaminated with

air.

C Check gas lines for cuts and loose fitting or

change gas cylinder.

8 Poor weld finish

Inadequate shielding

gas.

Increase gas flow or check gas line for gas

flow problems.

9 Arc start is not smooth.

A Tungsten electrode is

too large for the weld-

ing current.

A Select the right size electrode. Refer to Table

4-7 Current Ranges for Various Tungsten

Electrode Size.

B The wrong electrode

is being used for the

welding job.

B Select the right electrode type. Refer to Table

4-9 Tungsten Electrode Types.

C Gas flow rate is too

high.

C Select the right rate for the welding job. Refer

to Table 4-10.

D Incorrect shielding gas

is being used.

D Select the right shielding gas.

E Poor work clamp con-

nection to work piece.

E Improve connection to work piece.

10 Arc flutters during TIG

welding.

Tungsten electrode is

too large for the weld-

ing current.

Select the right size electrode. Refer to Table

4-7 Current Ranges for Various Electrode

Size.

11 Tungsten blackens due to

lack of shielding gas

A Gas valve on the TIG

Torch has not been

turned ON.

A Turn ON TIG Torch gas valve before you

commence welding.

B Gas cylinder valve OFF

or TIG Torch hose not

connected to regulator

B Turn ON gas cylinder valve or connect TIG

Torch hose to regulator.

Table 4-11: TIG (GTAW) Welding Problems