Fabricator 181i, 15 inserting wire into the wire feed mechanism – Tweco 181i Fabricator User Manual

Page 47

Fabricator 181i

Manual 0-51

91

3-17

INSTALLATION, OPERATION AND SETUP

Art #

A-10358

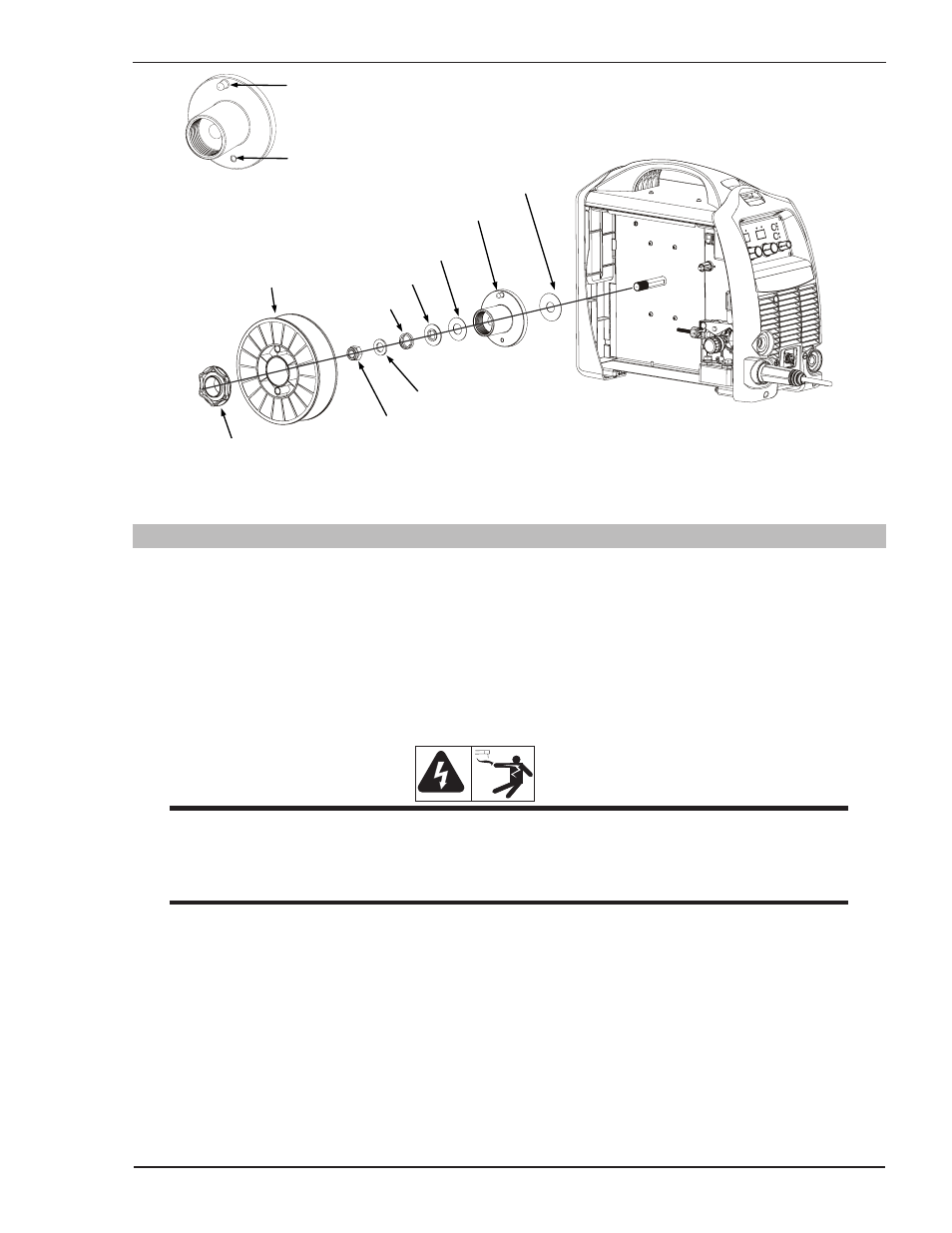

Spring

Nut with

Nylon Insert

8” (200mm)

diameter spool

Spool Hub Nut

Alignment pin

Brass Flat

Washer

Wire Spool Hub

Friction

Washer

Plastic Spacer

Flat Washer

Alternate

Alignment Pin

Position

Figure 3-10: 8" (200mm) Diameter Spool Installation

3.15 Inserting Wire into the Wire Feed Mechanism

Release the tension from the Pressure Roller Arm by turning the adjustable Wire Drive Tension Screw in an

counterclockwise. Then to release the pressure roller arm push the tension screw toward the front of the machine

which releases the pressure roller arm (Figure 3-11). With the MIG welding wire feeding from the bottom of the

spool (Figure 3-12) pass the electrode wire through the inlet guide, between the rollers, through the outlet guide

and into the MIG Gun.

Re-secure the pressure roller arm and wire drive tension screw and adjust the pressure accordingly (Figure 3-11).

Remove the contact tip from the MIG Gun. With the MIG Gun lead reasonably straight, feed the wire through the

MIG Gun by depressing the trigger switch. Fit the appropriate Velocity contact tip.

WARNING

Before connecting the work clamp to the work make sure the Electricity Supply is switched OFF.

The electrode wire will be at welding voltage potential while it is being fed through the system.

Keep MIG Gun away from eyes and face.