Fabricator 181i, 07 tig (gtaw) welding problems – Tweco 181i Fabricator User Manual

Page 80

Fabricator 181i

BASIC WELDING GUIDE

4-22

Manual 0-5191

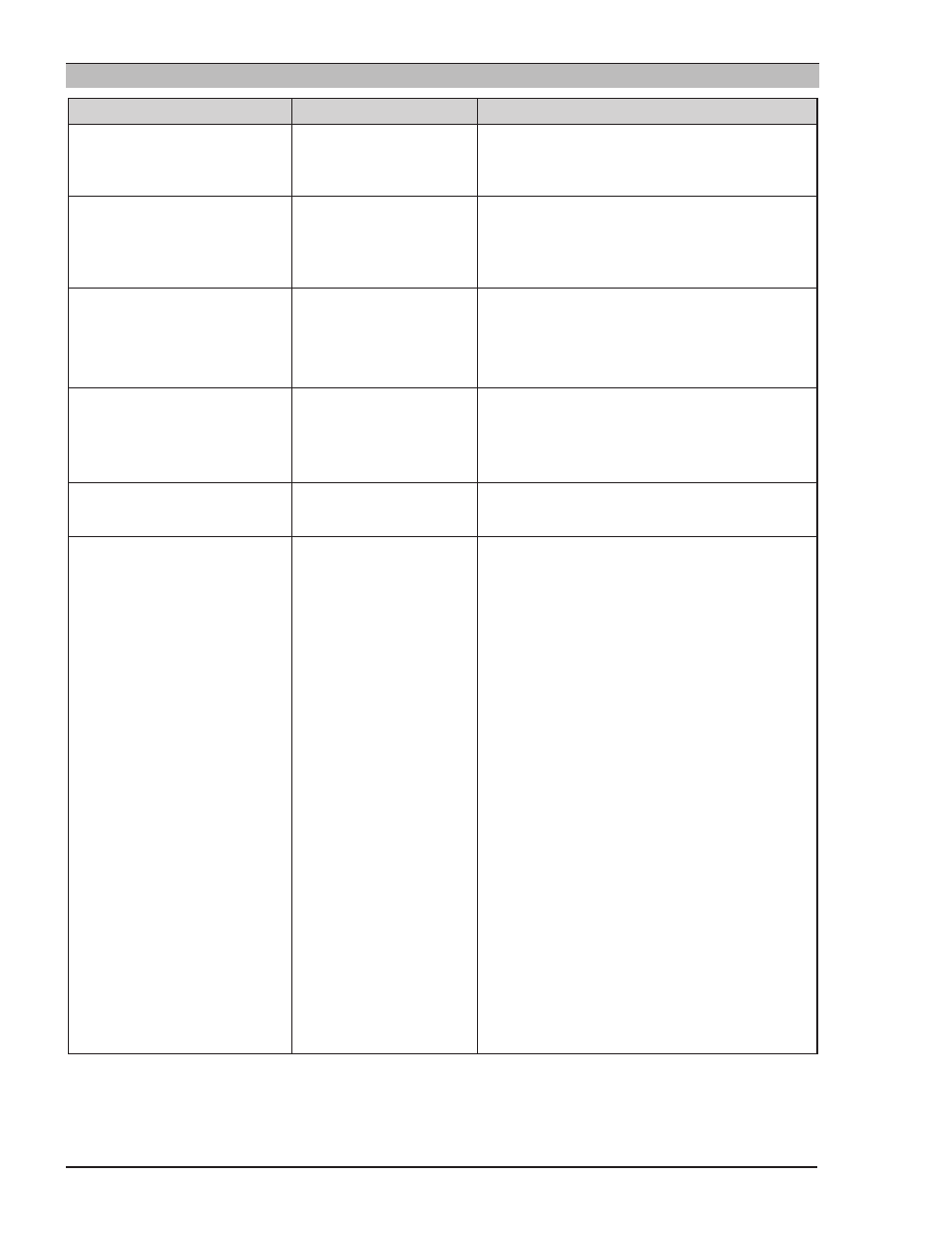

4.07 TIG (GTAW) Welding Problems

FAULT

CAUSE

REMEDY

1 Excessive bead build up or

poor penetration or poor

fusion at edges of weld.

Welding current is too

low

Increase weld current and/or faulty joint

preparation.

2 Weld bead too wide and

flat or undercut at edges

of weld or excessive burn

through.

Welding current is too

high

Decrease weld current.

3 Weld bead too small or

insufficient penetration or

ripples in bead are widely

spaced apart.

Travel speed too fast

Reduce travel speed.

4 Weld bead too wide or

excessive bead build up or

excessive penetration in

butt joint.

Travel speed too slow

Increase travel speed.

5 Uneven leg length in fillet

joint

Wrong placement of

filler rod

Re-position filler rod.

6 Electrode melts or oxidizes

when an arc is struck.

A TIG Torch lead

connected to positive

welding terminal.

A Connect TIG Torch lead to negative welding

terminal.

B No gas flowing to weld-

ing region.

B Turn TIG Torch gas valve ON. Check the gas

lines for kinks or breaks and gas cylinder

contents.

C TIG Torch is clogged

with dust or dirt.

C Clean TIG Torch.

D Gas hose is cut.

D Replace gas hose.

E Gas passage contains

impurities.

E Disconnect gas hose from the rear of Power

Source then raise gas pressure and blow out

impurities.

F Gas regulator turned

OFF.

F Turn ON.

G TIG Torch valve is

turned OFF.

G Turn ON.

H The electrode is too

small for the welding

current.

H Increase electrode diameter or reduce the

welding current.

I Power Source is set for

MIG welding.

I Set Power Source to LIFT TIG mode.