Fabricator 181i – Tweco 181i Fabricator User Manual

Page 46

Fabricator 181i

INSTALLATION, OPERATION AND SETUP

3-16

Manual 0-5191

Art # A-10357

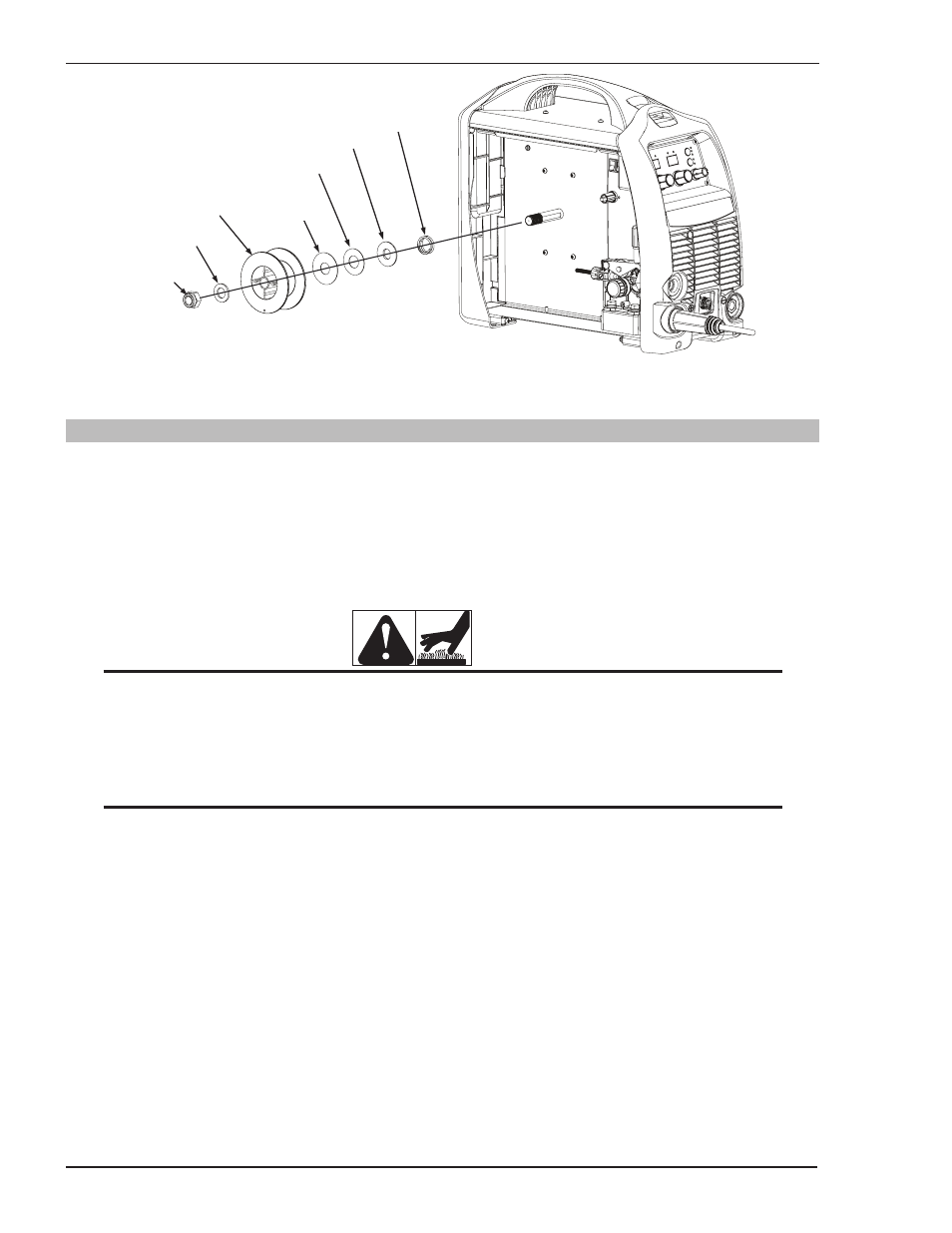

Friction Washer

4”(100mm)

Diameter spool

Nut with

Nylon Insert

Spring

Plastic Spacer

Brass Flat

Washer

Flat Washer

Figure 3-9: 4" (100mm)Diameter Spool Installation

3.14 Installing 8" (200mm) Diameter Spool

As delivered from the factory, the Power Source is set for a 8" (200mm) diameter spool.

In order to re-fit a 8" (200mm) spool assemble parts in the sequence shown below in Figure 3-10.

Adjustment of the nut with nylon insert will control the MIG Wire Spool Brake. Clockwise rotation of this nut with

nylon insert tightens the brake. The Brake is correctly adjusted when the spool stops within 3/8" (10mm) to 3/4"

(20mm) (measured at the outer edge of the spool) after MIG Gun trigger is released. Wire should be slack without

becoming dislodged from the spool.

CAUTION

Overtension of brake will cause rapid wear of mechanical WIREFEED parts, overheating of electrical

components and possibly an increased incidence of electrode wire Burnback into contact tip.

Ensure that the alignment pin on the wire spool hub aligns with the hole allocated in 8" (200mm)

diameter spool.

NOTE

This alignment pin can be removed by unscrewing in an counterclockwise direction and locating in the

appropriate position.