Ultra-cut 100 xt, 22 voltage divider for ihc torch height control – Tweco 100 XT Ultra-Cut Plasma Cutting System User Manual

Page 60

ULTRA-CUT 100 XT

3-38

INSTALLATION

Manual 0-5272

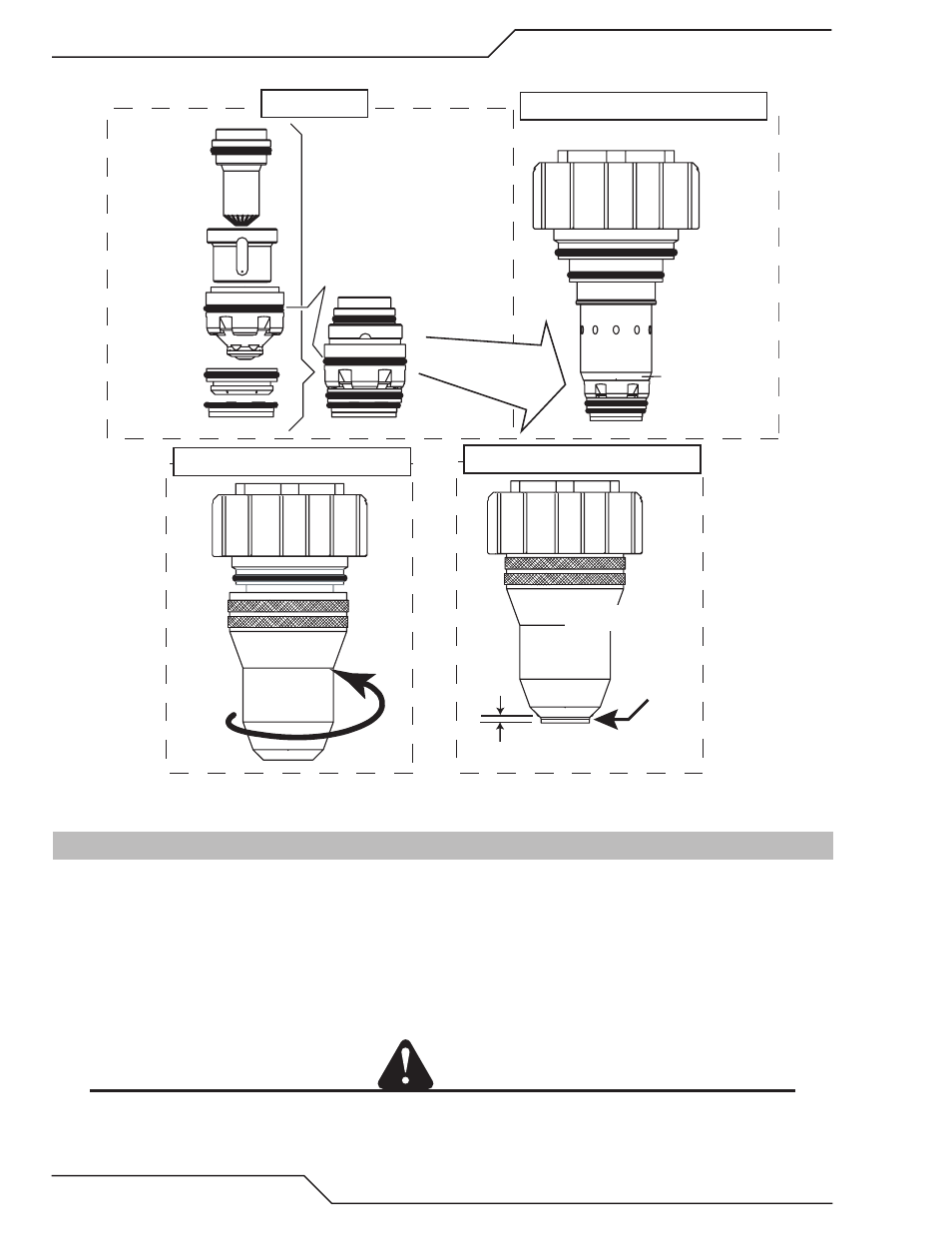

30 - 100 Amp Parts Assembly

Cartridge Covers

O-Ring

on Torch Tip

Shield Cap Protrudes

0.063-0.083" (1.6 - 2.1 mm)

Electrode

Plasma Gas

Distributor

Tip

Shield Gas

Distributor

Shield Cap

O-Ring

on Tip

1: Stack Parts

2: Press Cartridge onto Stacked Parts

4: Check Shield Cap Protrusion

Art # A-04873

No Gaps

Between Parts

3: Thread Shield Cup onto Cartridge

Shield Cap

Shield Cup

Installing Assembled Cartridge Onto Torch Head

3.22 Voltage Divider for iHC Torch Height Control

For best plasma cutting performance it is necessary to maintain a constant height (standoff) above the metal while

cutting. Cutting tables use a Torch Height Control (THC), also called a Z axis control, most of which use feedback

from the arc voltage to control the height. Several of these, including the iHC, part of the Victor Technologies XT

CNC Controller, come with a Voltage Divider Printed Circuit Board that has to be installed inside the plasma power

supply to divide the high arc voltage down to lower levels for use with control circuits.

There is a space for mounting the V-D Board located on the upper portion of an internal vertical panel near the rear

of the power supply. Predrilled holes for mounting the iHT V�D board as well as another popular height control

are provided.

CAUTION

If using another board that doesn’t align with the existing holes, remove the panel if possible before drilling. If not

possible then every precaution must be taken to keep metal filings from being deposited inside the power supply.