High precision plasma cutting system, Gcm 2010, Amperage set-up – Tweco 150 Ultra-Cut User Manual

Page 70

Manual No. 0-4800

4-6

OPERATION

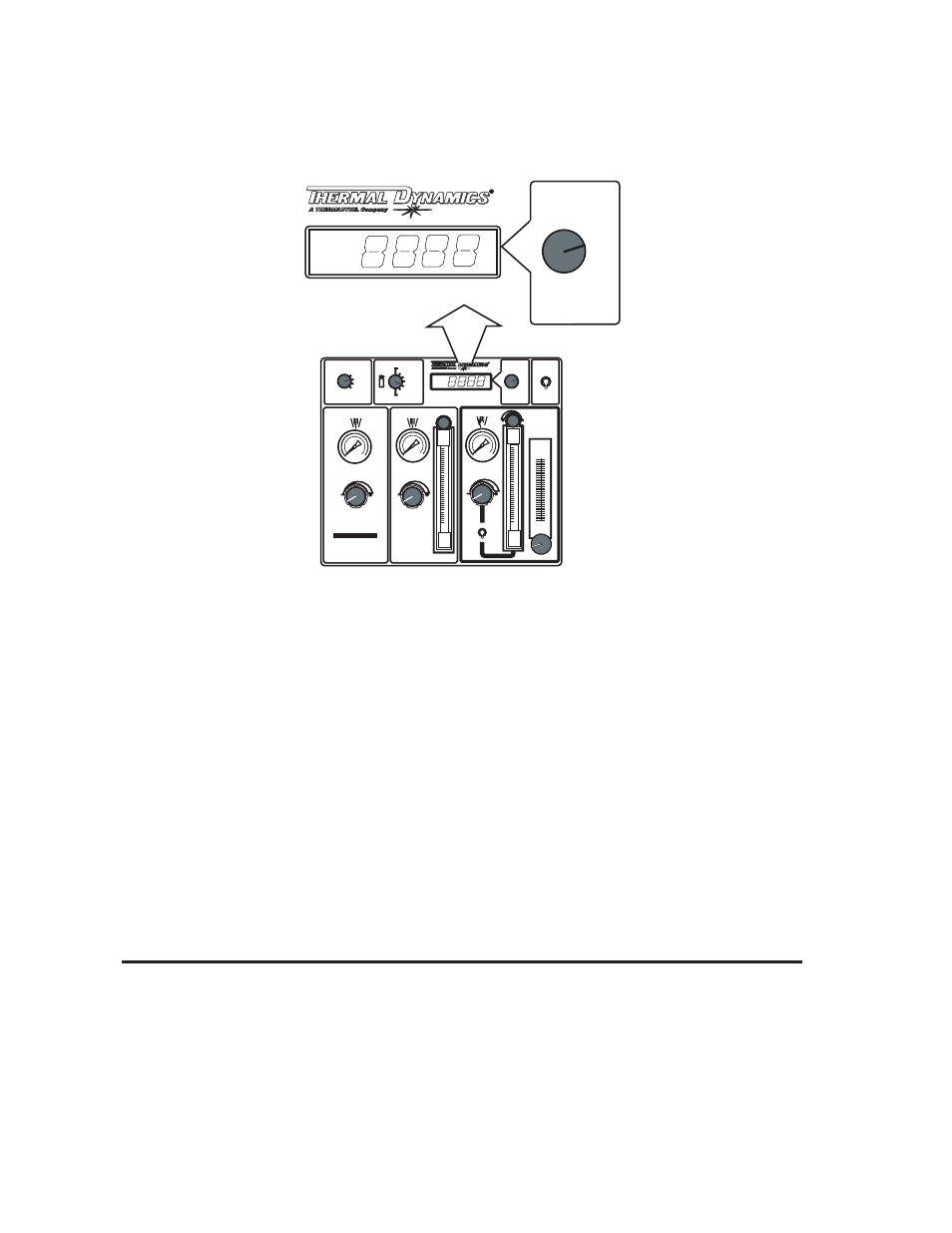

3. Amperage / Set-Up Knob

Adjusts the output amperage of the torch.

AMPERAGE

SET-UP

High Precision

Plasma Cutting System

PREFLOW

H

2

O

MIST

PLASMA

SHIELD

PRESSURE

PLASMA

POWER SUPPLY

GAS

FLOW

AMPERAGE

SET-UP

High Precision

Plasma Cutting System

ENABLE

DISABLE

GAS

MODE

RUN

SET PREFLOW

SET PLASMA

& SHIELD

TEST

O2 - AIR

O2 - O2

H35 -N

2

F5 - N

2

AIR - AIR

N

2 -

H

2

O

N

2 -

N

2

9

9

Art # A-04767

GCM

2010

4. Plasma Power Supply Enable / Disable Switch

In the DISABLE position, stops the system from starting a pilot arc at the torch, while the operator selects and

adjusts gases, or changes torch parts. The DISABLE position also stops coolant and gas flow. In the ENABLE

position, allows normal operation (under control of the CNC device).

5. PREFLOW Control Knob and Pressure Gauge

Used to set preflow gas pressure. MODE switch must be in PREFLOW position.

6. PLASMA and SHIELD Control Knobs, Pressure Gauges, and Flow Meters

Used to set plasma and shield gas pressures and flows. MODE switch must be in SET PLASMA & SHIELD

position.

7. H

2

O Mist Control Knob and Flow Meter

Used to set water flow rate. MODE switch must be in SET PLASMA & SHIELD position. GAS selection

switch must be in N

2

-H

2

O position.

NOTE

Water mist is not used in all applications.