tekmar 667 Snow Detector & Melting Control User Manual

Page 13

13 of 28

© 2002 D 667 - 09/02

• Run wire from other system components (pumps, boiler, etc.) to the control.

• Run wires from the 115 V (ac) power to the control. Use a clean power source with a minimum 15 A circuit to ensure proper

operation. Multi-strand 16 AWG wire is recommended for all 115 V (ac) wiring due to its superior flexibility and ease of installa-

tion into the terminals.

STEP FOUR

––––––––––

ELECTRICAL CONNECTIONS TO THE CONTROL

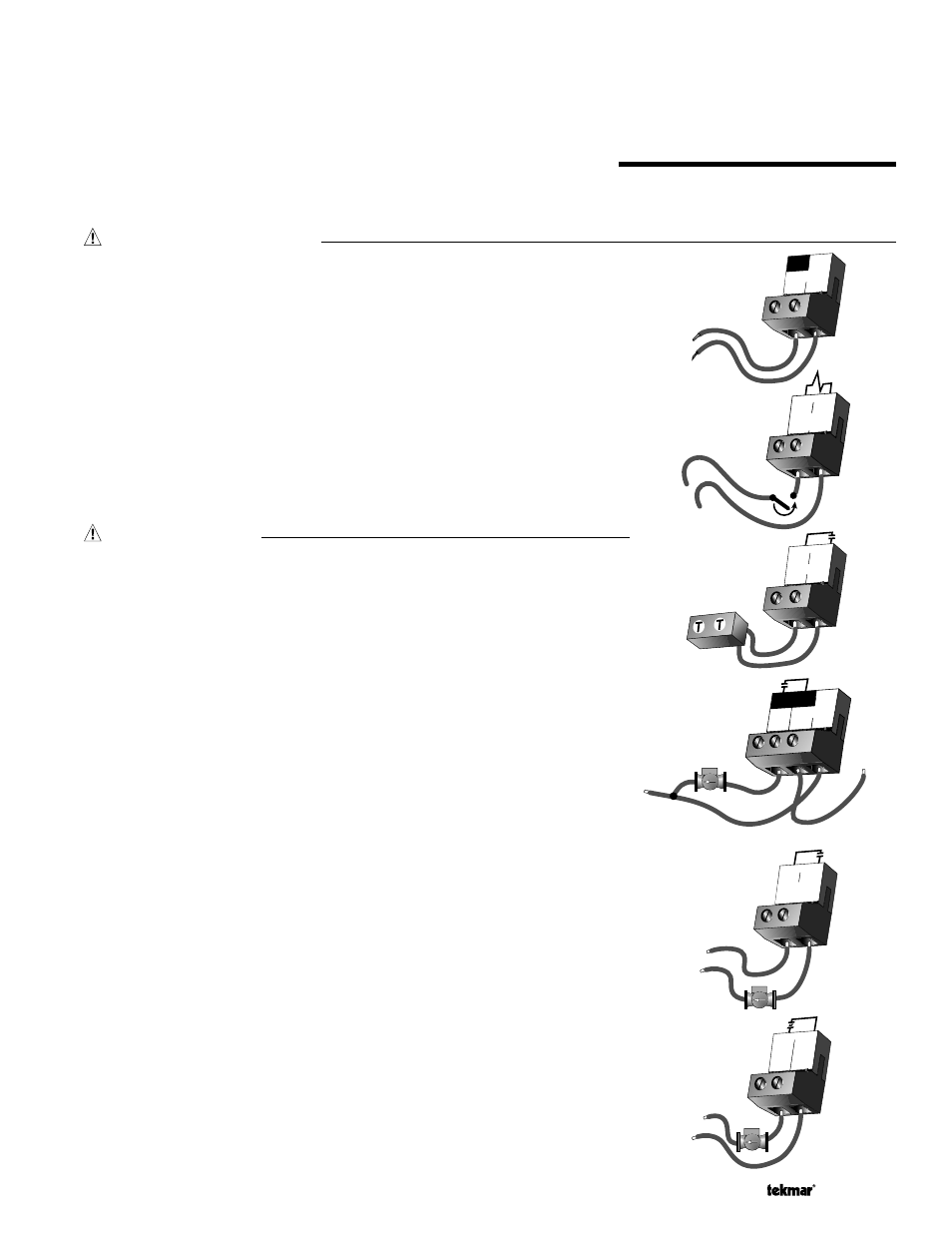

The installer should test to confirm that no voltage is present at any of the wires. Push the control into the base and slide it down

until it snaps firmly into place.

Powered Input Connections

Power

25

115 V (ac)

L

N

24

115 V (ac) Power

Connect the 115 V (ac) power supply to the Power L and Power N terminals (24

and 25). This connection provides power to the microprocessor and display of the

control. As well, this connection provides power to the Sys P1 terminal (23) from the

Power L terminal (24).

Melt / Idle Demand

To generate a melt demand or idle demand, a voltage between 24 V (ac) and

240 V (ac) must be applied across the Melt/Idle Demand terminals (15 and 16).

Output Connections

Boiler Contacts

The Boiler terminals (19 and 20) are an isolated output in the 667. There is no power

available on these terminals from the control. These terminals are used as a switch

to either make or break the boiler circuit. When the 667 requires the boiler to fire, it

closes the contact between terminals 19 and 20.

System Pump Contact (Sys P1)

The Sys P1 output terminal (23) on the 667 is a powered output. When the relay in

the 667 closes, 115 V (ac) is provided to the Sys P1 terminal (23) from the Power L

terminal (24). To operate the system pump, connect one side of the system pump

circuit to terminal 23 and the second side of the pump circuit to the neutral (N ) side

of the 115 V (ac) power supply.

System Pump Contact (System Pmp 2 )

The System Pmp 2 terminals (17 and 18) are an isolated output in the 667. There is

no power available on these terminals from the control.

If the System Pmp 2 contact is used, connect the pump circuit to the System Pmp

2 terminals (17 and 18).

Melting Contact

The Melting terminals (21 and 22) are an isolated output in the 667. There is no

power available on these terminals from the control. These terminals are used as a

switch to make or break an external circuit.

Variable Speed Injection Pump

The 667 can vary the speed of a permanent capacitor, impedance protected or

equivalent pump motor that has a locked rotor current of less than 2.4 A. Most

small wet rotor circulators are suitable as described in Essay E 021. The 667 has an

internal overload fuse which is rated at 2.5 A 250 V (ac). Contact your tekmar sales

representative for details on the repair procedures if the fuse is blown.

15

Melt / Idle

Demand

16

24 to 240 V (ac)

Boiler

20

19

Sys

P1

115 V (ac)

N

L

Power

25

L

N

24

23

17 18

L

N

115 V (ac)

System

Pmp 2

1

Var

2

Pwr

Mix

115 V (ac)

N

L