Settings, Step six – tekmar 662 Snow Detector & Melting Control User Manual

Page 7

7

Melting Surface Temperature

The “Melting” dial setting is the desired slab surface temperature when the control is in melting mode and is

also used as the Warm Weather Cut Off temperature. The “Melting” temperature is usually set based on local

weather conditions. In some areas, heavy snowfall can load a slab at temperatures well above freezing; in

these areas, the dial should be set higher. If the melting system response is sluggish, increasing the “Melting”

dial setting can cause the system to melt faster; however, it is important to remember that increasing this

setting generally increases energy consumption.

Idling Surface Temperature

The “Idling” dial setting is based on the requirements of the user. If minimizing the time required for the slab

to reach “Melting” temperature is important then the dial is set slightly below freezing (<32

°F). If black ice or

frost formation is a concern, the dial is set slightly above freezing (>32

°F). It is important to remember that

“Idling” increases energy consumption. “Idling” can also be turned Off.

Water Detection Sensitivity

The sensitivity of the Snow/Ice Sensor to water can be adjusted using the “Sensitivity” dial. As snow becomes

contaminated with dirt, and as the sensor surface itself becomes dirty, the control may incorrectly indicate

the presence of water. If this condition occurs, clean the surface of the sensor and/or turn down the sensitivity

setting. If the snow and rain in your area is very clean, the sensitivity setting may need to be increased before

snow is detected.

Settings

Step Six

Essential control settings

Before adjusting the dial settings, read through the sequence of operation to ensure that you understand how the control operates.

The dials are factory set at the midpoint of each setting. This reflects typical settings for many systems and is therefore a good

starting point.

Note: The Snow/Ice Sensor 090 is installed in a hostile environment and should be cleaned on a regular basis with a wire

brush. After cleaning, check operation by pressing the test button to cycle the control through the test routine.

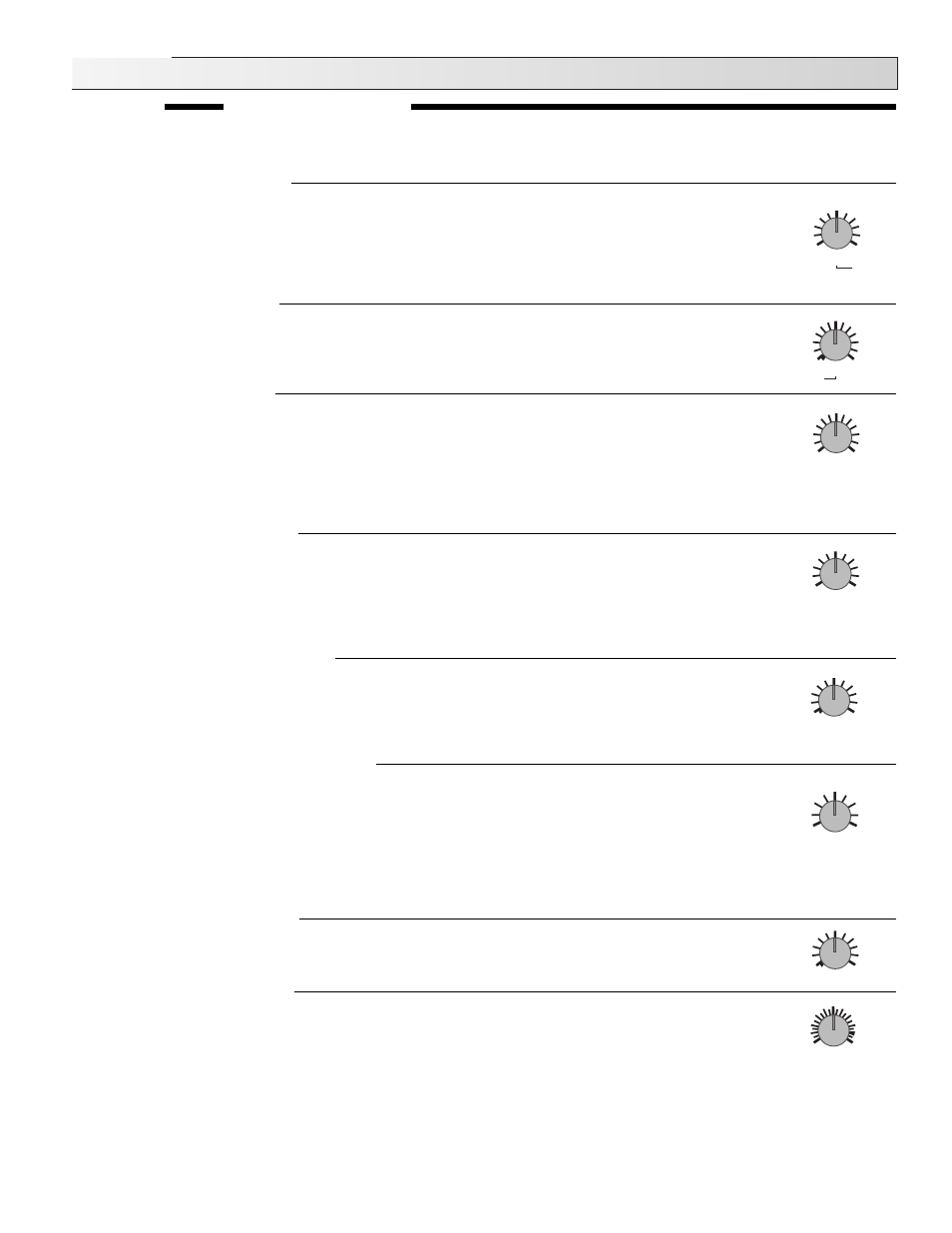

Maximum Supply Temperature

Some tubing manufacturers recommend that their products not be operated continuously at temperatures

greater than 140

°F (60°C). Engineers also recommend that concrete slabs not be subjected to temperatures

in excess of 160

°F (70°C). This dial setting permits the installer to limit the maximum temperature of the water

supplied to the snow melting slab. If the system supply water temperature approaches this setting, the

“Maximum Supply” light turns on and the control operates the mixing valve (or variable speed pump) to limit

the output and reduce the “Supply” temperature.

Minimum Boiler Return Temperature

To prevent problems of flue gas condensation in the boiler, this adjustment is set to the minimum boiler return

temperature as specified by the boiler manufacturer. When the boiler return approaches this setting, the

“Minimum Return” light turns on and the control operates the mixing valve (or variable speed pump) to limit

the output until the boiler return can warm up. If a minimum boiler return temperature is not required, as with

condensing or electric boilers, this adjustment can be set to “Off”.

∆T Max. (Maximum Rate of Heat Delivery )

The 662 control limits the rate of heat applied to a slab to prevent excessive thermal stress. The rate of heat

delivery to the slab is dependant on the difference between the melting system supply and return

temperatures. The control measures these temperatures and calculates the difference to give the

∆T. If this

calculated

∆T approaches the “∆T Max” setting, the control operates the valve or pump to maintain the ∆T

at the “

∆T Max” setting. The “∆T Max” dial is normally set at 5°F to 10°F above the design ∆T or it is specified

directly by the system designer. If this is not the case, set the dial at 30

°F.

Note: The control may exceed its “

∆T Max” setting if the supply temperature is lower than 30°F (see page 2 —

∆T compensation for changes in fluid viscosity).

CWCO (Cold Weather Cut Off)

The “CWCO” is the lowest temperature at which the melting system continues to operate. This temperature

is set based on the capacity of the snow melt system and the economics of melting in extreme conditions.

Motor Speed / Pump Response

Pump Response (variable speed pump) - When using a variable speed pump, this dial sets the minimum

time required for the injection pump to go from 0% to 100% speed (ramp up). The primary purpose of limiting

the pump ramp up time is to avoid instability. If the pump ramps up faster than the snow melt system can

respond, the pump may continually ramp up and down trying to satisfy the snow melt system. For example:

A heat exchanger between the boiler loop and the system loop with heavy steel pipe that is slow to transfer

heat, has a delay between the time the control signals the pump to add heat to the system and the time the heat can affect

the system and be sensed by the control. To prevent oscillations of the pump speed, the “Pump Response” is set to a longer

time. In a system with a low mass, dedicated, high input boiler and no heat exchanger, the system responds faster and therefore

a shorter time can be set on the “Pump Response” dial. To avoid pump instability, experimentation is usually required; however,

most standard installations work well with settings in the 30 to 50 second range.

Sensitivity

50%

20

80

Max. Supply

150

°F

100

200

Melting

Surface

39

°F

34

44

Idling

29

°F

Off

35

24

Surface

Min. Boil. Return

100

°F

Off

150

60

10

30

°F

50

∆T Max

Off

CWCO

0

°F

-25

25

30

130 sec

230

Motor Speed /

Pump Response

tekmar

motor