Step five – tekmar 662 Snow Detector & Melting Control User Manual

Page 6

6

Step Five

Testing the wiring

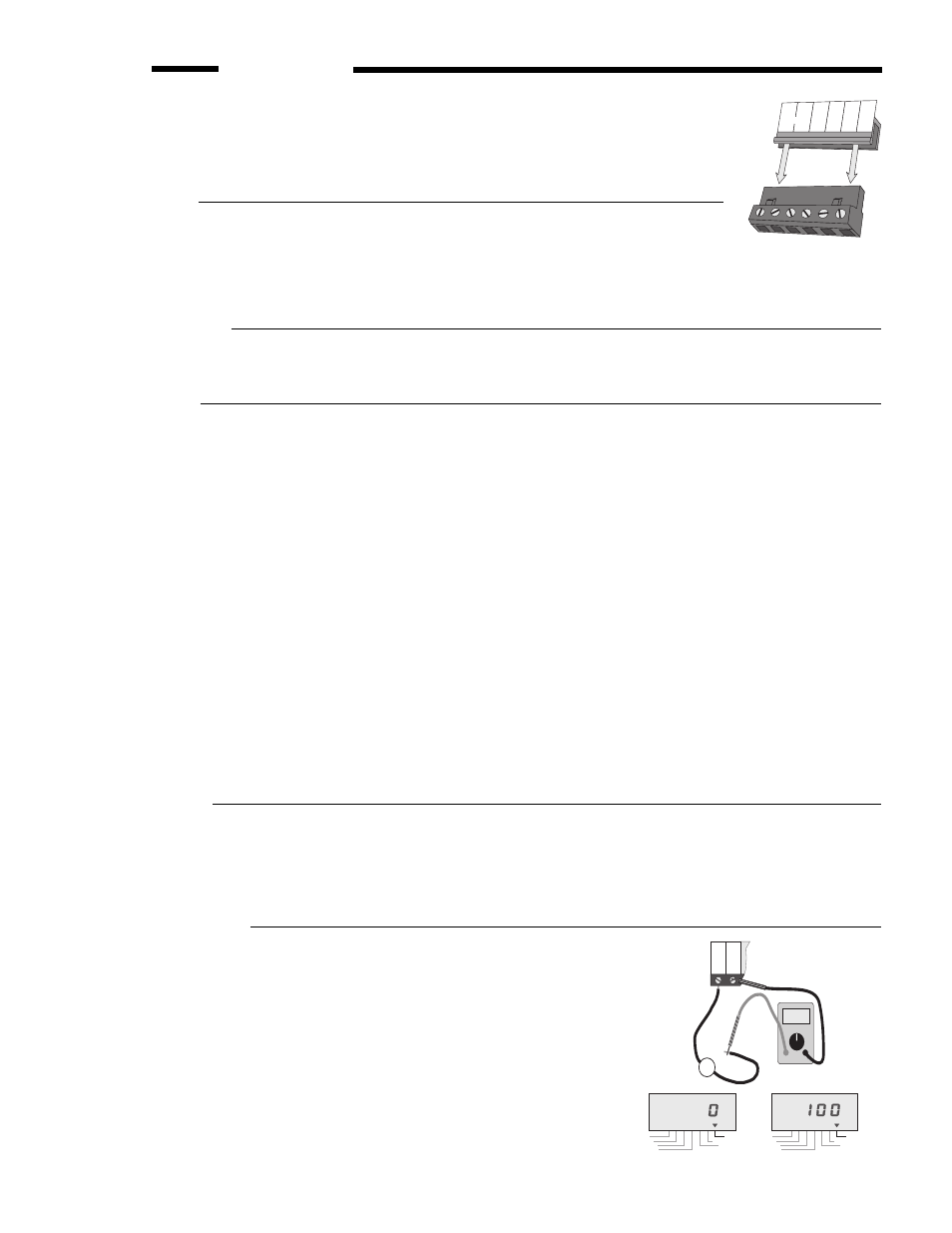

• Before applying power to the control for testing, each terminal plug must be unplugged from its

header on the control. Pull straight down to unplug.

• These tests are to be performed using standard testing practices and procedures and should only

be carried out by properly trained and experienced persons.

• A good quality electrical test meter capable of reading from at least 0 — 200 Volts ac, and at least

0 — 2,000,000 Ohms, is essential to properly test this control.

Test the sensors

• In order to test the sensors, the actual temperature at each sensor must be known. A good quality

digital thermometer with a surface temperature probe is recommended for ease of use and

accuracy of testing. Where a thermometer is not available, a spare sensor can be strapped

alongside the one to be tested and the readings compared. Test the Snow/Ice Sensor 090

according to the instructions in brochure D 090, and the remaining sensors according to the

brochure D 001.

Test the power supply

• Before applying power, make sure exposed wiring or terminals are not grounded or in contact with other wires. Turn on the

120 V ac power and, using an AC voltmeter, measure the voltage between terminals

Power N – L (5 and 6). You should measure

between 110 and 130 V ac.

Test the Outputs

• If a device is connected to the

Melt (1 and 2) terminals, make sure power to the circuit is off and install a jumper in the terminal

plug between terminals 1 and 2. When the device is powered up, it should operate. If it does not turn on, check the wiring

from the terminal plug to the device and refer to any installation or trouble shooting information supplied with the device. If

the device is operating properly, disconnect the power and remove the jumper.

• Repeat this procedure for any devices connected to the

Warning (3 and 4) terminals and the Boiler (11 and 12) terminals.

• If a pump is connected to the

P1 Pmp (8) terminal, make sure power to the circuit is off

and install a jumper in the terminal plug

between the

Com Pmp — P1 Pmp (7 and 8) terminals. When the circuit is powered up, the pump should start. If it does not,

check the wiring from the terminal plug to the pump and refer to any installation or troubleshooting information supplied with

the pump. If the pump operates properly, disconnect the power and remove the jumper. Repeat this procedure for a pump

connected to the

P2 Pmp (9) terminal.

• If a variable speed pump is connected to the

Power N — Var Pmp (5 and 10) terminals, make sure power to the circuit is off

and install a jumper in the terminal plug between the

Power L — Var Pmp (6 and 10) terminals. When the 120 V ac circuit is

powered up, the variable speed pump should operate at full speed. If it does not, check the wiring from the terminal plug to the

pump and refer to any installation or troubleshooting information supplied with the pump. If the pump operates properly,

disconnect the power and remove the jumper.

• A separate 24 V ac transformer is used to drive the actuating motor for the mixing valve. Make sure power to the transformer

is off and install a jumper in the terminal plug between terminals

Com Mix – Opn Mix (15 and 16). When the transformer is

powered up, the mixing valve should drive fully open and then stop. Turn off the power to the transformer, remove the jumper

and install it in the terminal plug between terminals

Com Mix – Cls Mix (15 and 17). When the transformer is powered up,

the mixing valve should drive fully closed and then stop. If it does, disconnect the power and remove the jumper.

• The 4 - 20 mA output terminals (13 and 14) cannot be tested without power applied to the control. Since no power is supplied

to the control at this point, the 4 - 20 mA output cannot be tested. Please refer to the operation test below.

Connect the control

• Turn the power off and make sure all test jumpers have been removed from the plugs.

• Connect the plugs to the control by carefully aligning them with their respective headers and pushing them upwards. The plugs

should snap firmly into the headers.

• Install the supplied safety divider(s) between the low voltage (less than 30 V ac) and the line voltage (120 V ac) wiring chambers.

Apply power to the control.

Test the 4 - 20 mA output

The 4 - 20 mA device can be tested as follows:

• Connect the positive wire from the 4 - 20 mA device to terminal 13 on the control.

• Connect the negative wire from the 4 - 20 mA device to the red (+) lead on the

milliamp meter.

• Connect the black (-) lead from the milliamp meter to terminal 14 on the control.

• When the Opening light turns on, the initial percentage output is zero and the meter

should read 4 mA.

• As the % Output increases, the meter reading should increase until 100% Output

is reached at which point the meter should read 20mA.

• When the Closing light comes on the meter should start at 20mA and eventually

reach 4mA when the display shows 0% Output.

5

6

8

9

10

P1

Pmp

N

Var

Pmp

P2

Pmp

7

Com

Pmp

L

Power

Disconnect terminal

plug from its header

Reading should

be 20 mA

Slab

Supply

Actual

∆T

Target

∆T

% Output

Usage (

∆T x hrs)

Boiler Return

Reading should

be 4 mA

Slab

Supply

Actual

∆T

Target

∆T

% Output

Usage (

∆T x hrs)

Boiler Return

Milliamp

6.4 mA

Test the 4 - 20 mA

output using a

milliamp meter

1000 mA = 1 amp

14

13

+

4-20

1

C

M

–

4-20

M

+

-