Sequence of operation, Defi nitions – tekmar 279 Steam Control User Manual

Page 4

©

2010 D

279

-

05/10

4

of

24

Establishing Steam

Section B

Sequence of Operation

Powering up the control

When the control is powered on, all segments in the LCD

are turned on for 2 seconds. Next, the control displays the

control type number in the LCD for 2 seconds. Next, the

software version is displayed for 2 seconds. Last, the control

enters into the normal operating mode.

Boiler Contact Operation

In single on-off steam boiler applications, the control uses

the boiler contact to connect to the thermostat terminals

(T-T) on the boiler. The pressure control and all other safety

devices and circuits must continue to be wired in series to

the burner circuit. The boiler contact on the control is used

to turn on or off the steam boiler burner.

In steam valve applications, the boiler contact on the control

is used to power the valve motor to open the valve. When

power is removed, the valve must close.

Status

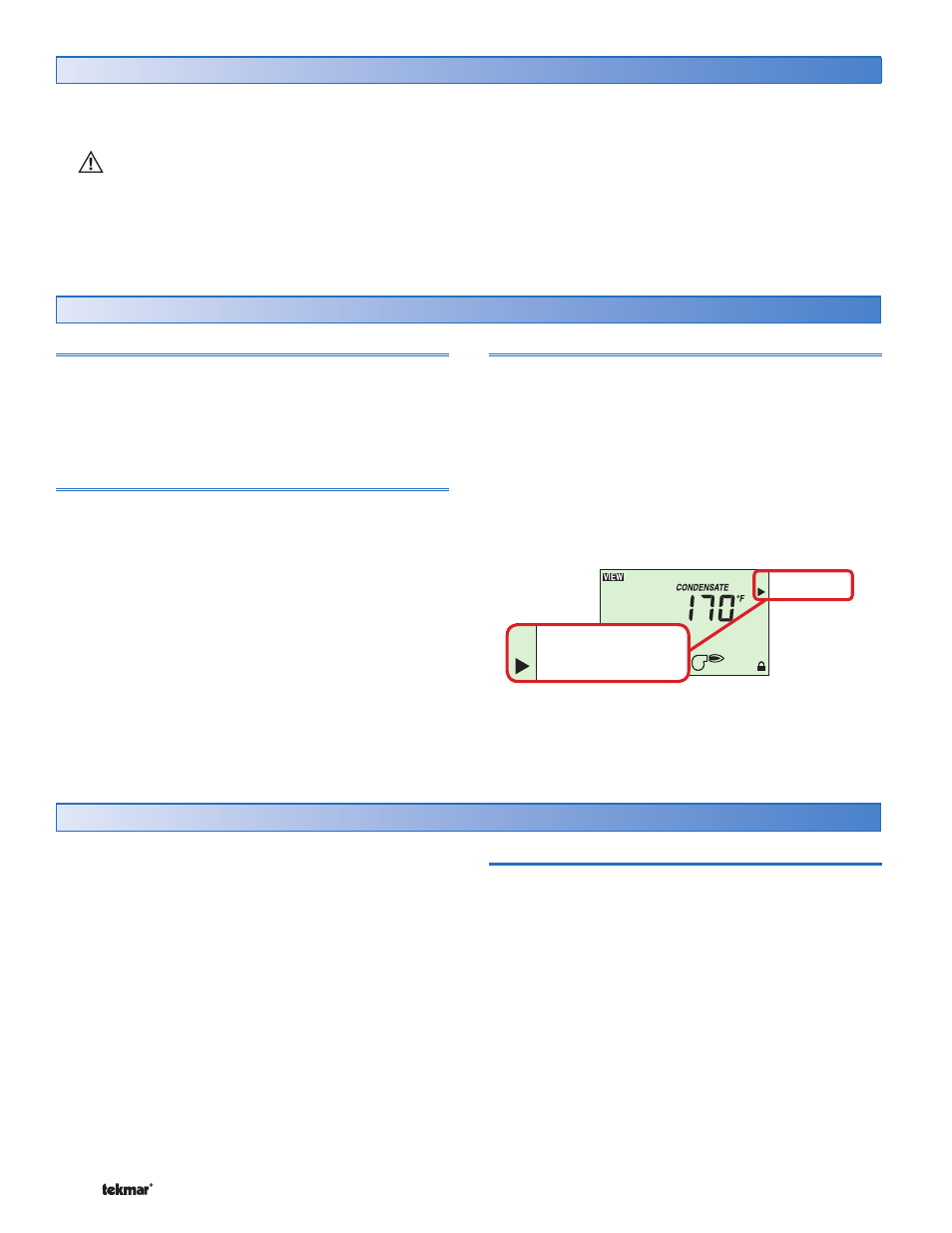

The control has a status field on the right hand side of the

control. A pointer is shown in the status field once the boiler

contact is turned on. The pointer indicates at which point

of the steam heating system cycle the control is currently

operating at.

The steps are as follows:

Establishing Steam

Heat Cycle

Lockout Differential

DHW Tankless Coil Heating

STATUS

Establishing Steam

Heat Cycle

Lockout Differential

DHW Tankless Coil Heating

STATUS

Establishing Steam

Each of these steps are described in detail in the following

sections.

•

•

•

•

General

Section A

In steam heating systems, there is a time delay between

when the steam boiler or steam valve is turned on and

when the steam finally reaches the furthest radiator in the

system. It is important for the control to determine how

long this time delay is in order to ensure proper heating in

all rooms. When heat is required, the control activates the

boiler relay but does not consider the heating cycle to start

until steam has been established at the furthest radiator.

While the control is waiting to establish steam, the Status

field will have a pointer indicating Establishing Steam.

The control can use one of two methods to determine the

time to establish steam.

Condensate Return Sensor

The Universal Sensor 071 included with the control can be

used to measure the temperature of the condensate return

pipe. In a one pipe system, it is recommended to install the

sensor on the bottom of the pipe just before it enters the last

radiator. In a two pipe system, it is recommended to install

the Condensate Sensor on the bottom of the condensate

return pipe of the radiator furthest from the boiler. In cases

where access to the furthest radiator is not possible, an

alternative is to locate the sensor on the bottom of the

condensate return pipe in the mechanical room. Once the

condensate sensor is installed, ensure the Condensate

Sensor /Off Switch Setting to Condensate Sensor. The

measured condensate return temperature reading is visible

in the View menu.

Defi nitions

The following defined terms and symbols are used throughout this manual to bring attention to the presence of hazards of

various risk levels, or to important information concerning the life of the product.

Caution: Refer to accompanying documents.