Troubleshooting – tekmar 279 Steam Control User Manual

Page 21

21 of 24

© 2010 D 279 - 05/10

Establish the problem. Get as much information from the customer as possible about the problem.

Is there too much heat, not enough heat, or no heat? Is the problem only in one particular zone or

area of the building or does the problem affect the entire system? Is this a consistent problem or only

intermittent? How long has the problem existed for? This information is critical in correctly diagnosing

the problem.

Understand the sequence of operation of the system. If a particular zone is not receiving enough heat,

which pumps or valves in the system must operate in order to deliver heat to the affected zone? If the

zone is receiving too much heat, which pumps, valves or check valves must operate in order to stop

the delivery of heat?

Press the Test button on the control and follow the control through the test sequence as described in

the Testing section. Pause the control as necessary to ensure that the correct device is operating as

it should.

Sketch the piping of the system. This is a relatively simple step that tends to be overlooked, however

it can often save hours of time in troubleshooting a system. Note flow directions in the system paying

close attention to the location of pumps, check valves, pressure bypass valves and mixing valves. Ensure

correct flow direction on all pumps. This is also a very useful step if additional assistance is required.

Troubleshooting

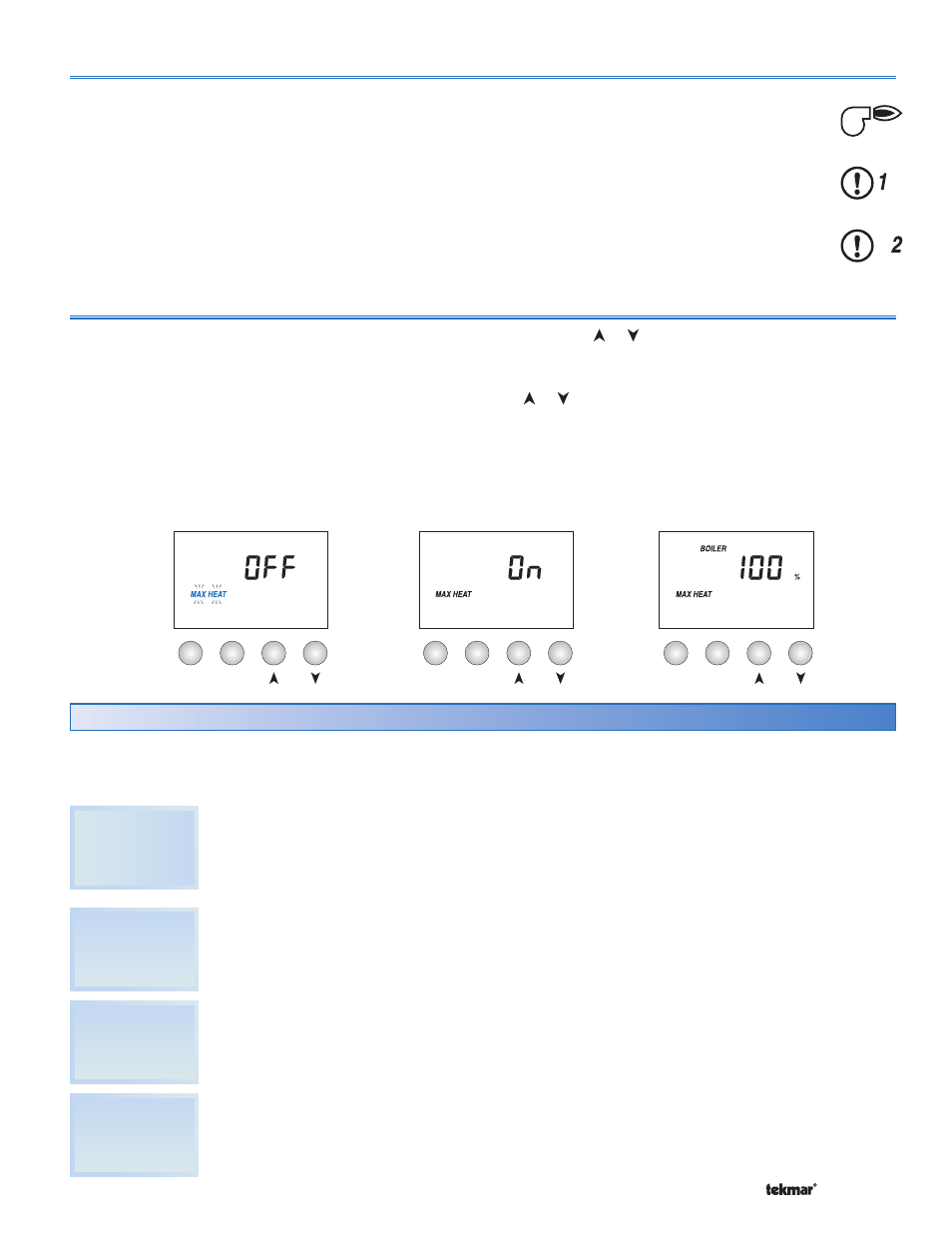

The control has a function called Max Heat. In this mode,

the control turns on and operates the steam system at the

percent output selected. The control continues to operate

in this mode for up to 24 hours or until the Menu, Item or

Test button is pressed.

To enable the Max Heat feature, use the following

procedure.

Press and hold the Test button for more than 3

seconds. At this point, the control flashes the MAX

HEAT segment and displays the word OFF.

1.

Establish the

Problem

Understanding

the Sequence of

Operation

Use the Test

Routine

Sketch the

Piping in the

System

When troubleshooting any heating system, it is always a good idea to establish a set routine to follow. By following a

consistent routine, many hours of potential headaches can be avoided. Below is an example of a sequence that can be

used when diagnosing or troubleshooting problems in a steam heating system.

Each step in the test sequence lasts 10 seconds.

During the test routine, the test sequence may be paused

by pressing the Test button. If the Test button is not pressed

again for 5 minutes while the test sequence is paused, the

control exits the entire test routine. If the test sequence is

paused, the Test button can be pressed again to advance

to the next step. This can also be used to rapidly advance

through the test sequence. To reach the desired step,

repeatedly press and release the Test button until the

appropriate device and segment in the display turn on.

Step 1

Turn on the Boiler relay for 10 seconds, then

shut off.

Step 2

Turn on the Alert 1 relay for 10 seconds,

then shut off.

Step 3

Turn on the Alert 2 relay for 10 seconds,

then shut off.

Menu

Item

Menu

Item

Menu

Item

Using the or button, select the word On. After 3

seconds the Boiler % is shown.

Select the desired boiler output percentage using the

or buttons.

To cancel the Max Heat mode, press the Menu, Item,

or Test button.

Once the Max Heat mode has either ended or is

cancelled, the control resumes normal operation.

2.

3.

4.

5.

Test Sequence

Max Heat