tekmar 268 Boiler Control User Manual

Page 8

© 2010

D 268 - 11/10

8 of 32

BOILER MASS

The BOIL MASS setting allows the installer to adjust the control to the thermal mass of the type of heat sources used in the

application. The BOIL MASS setting also adjusts the minimum inter-stage delay time when operating with an automatic differential.

Lo

(1)

The Lo setting is selected if the boiler(s) that is used has a low thermal mass. This means that the boiler(s) has a very small water

content and has very little metal in the heat exchanger. A boiler that has a low thermal mass comes up to temperature quite rapidly

when fired. This is typical of many copper fin-tube boilers. The Lo MASS setting provides the quickest staging on of boilers.

Med

(2)

The Med setting is selected if the boiler(s) that is used has a medium thermal mass. This means that the boiler(s) either has a

large water content and a low metal content or a low water content and a high metal content. This is typical of many modern

residential cast iron boilers or steel tube boilers. The Med MASS setting stages on additional boilers at a slower rate than the

Lo MASS setting.

Hi

(3)

The Hi setting is selected if the boiler(s) that is used has a high thermal mass. This means that the boiler(s) has both a large water

content and a large metal content. A boiler that has a high thermal mass is relatively slow in coming up to temperature. This is

typical of many commercial cast iron and steel tube boilers. The HI MASS setting stages on additional boilers at the slowest rate.

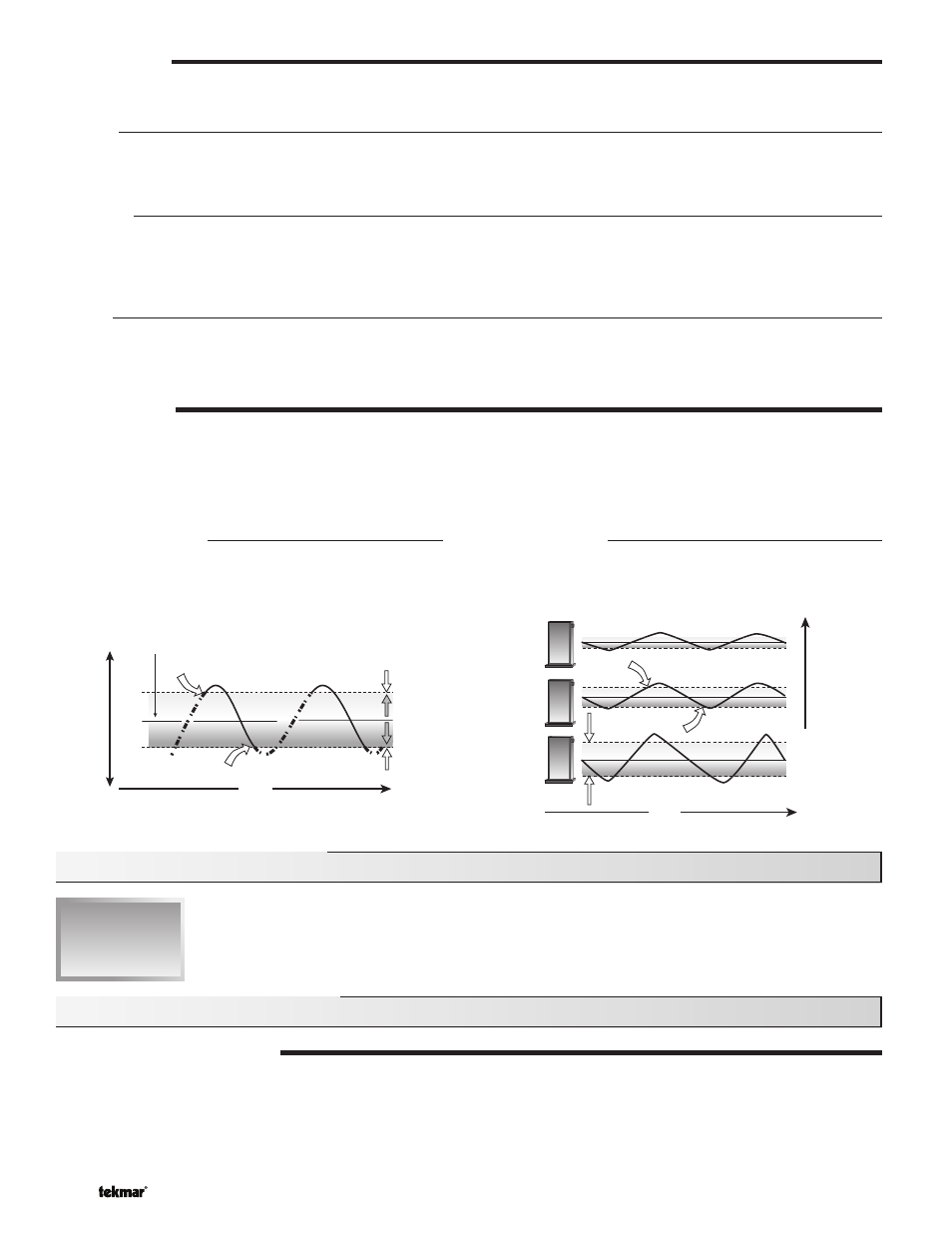

DIFFERENTIAL

An on / off heat source must be operated with a differential in order to prevent short cycling. With the control, either a fixed or an

auto differential may be selected. The boiler differential is divided around the boiler target temperature. The first stage contact

closes when the supply water temperature is ½ of the differential setting below the boiler target temperature. Additional stages

operate if the first stage is unable to bring the supply water temperature up to the boiler target temperature at a reasonable rate. As

the supply temperature reaches ½ of the differential above the boiler target temperature, stages are staged off.

Section C1

Pump

Operation

PRIMARY PUMP OPERATION

The primary pump operates under the following conditions:

•

The control receives a boiler demand and is not in warm weather shut down (WWSD).

•

The control receives a DHW demand when DHW MODE is set to 3 or 4.

•

The control receives a setpoint demand and setpoint MODE is set to 3.

Te

m

pe

ra

tu

re

fa

ll

Te

m

pe

ra

tu

re

ri

se

Cooler T

emperature W

armer

Time

Desired temperature

160°F (71°C)

Differential

10°F (6°C)

Boiler Off

Boiler On

155°F (68°C)

165°F (74°C)

Heating Load

On

Differential

Off

Time

Auto Differential

If the Auto Differential is selected, the control automatically

determines the best differential as the load changes. This

reduces potential short cycling during light load conditions.

Section C: Pump Operation

Section C1: Pump Operation

Fixed Differential

If the user desires to have a fixed differential, this is set

using the BOIL DIFF setting in the ADJUST menu.