tekmar 264 Boiler Control User Manual

Page 5

5 of 32

© 2008 D 264 - 12/08

COMBUSTION AIR OR ALARM CONTACT

The control has an isolated contact that can be used as either a combustion air damper contact or an alarm contact. This selection

is made using the C. A. / Alarm DIP switch.

Combustion Air

(C. A.)

When the DIP switch is set to C. A., terminals 12 and 13 can be used as a switch to operate a combustion air damper. This contact

closes prior to the first stage operating on the control. The amount of time that the contact closes prior to the first stage operating

is set using the combustion delay setting.

The combustion air contact remains closed for a minimum of 15 seconds after the last stage is turned off.

Alarm

When the DIP switch is set to Alarm, terminals 12 and 13 can be used as a switch to operate an alarm circuit. This contact closes

whenever an error message is present on the control. When the alarm contact is activated, refer to the Error Messages section

of this brochure to determine the cause of the alarm. Once the fault has been fixed, the alarm can be cleared by pressing either

the Menu, Item,

▲

or

▼

button.

Boiler Alarm

The control can monitor the boiler supply temperature and provide an alarm if the temperature does not increase within a cer-

tain amount of time. The amount of time can be set using the Boiler Alarm setting. This alarm can be used to determine if the

boilers have failed to fire. To reset the alarm, press and hold the

▲

and

▼

buttons for 5 seconds while in the VIEW menu.

1

2

3

3

2

1

720 hours

690 hours

672 hours

672 hours

690 hours

720 hours

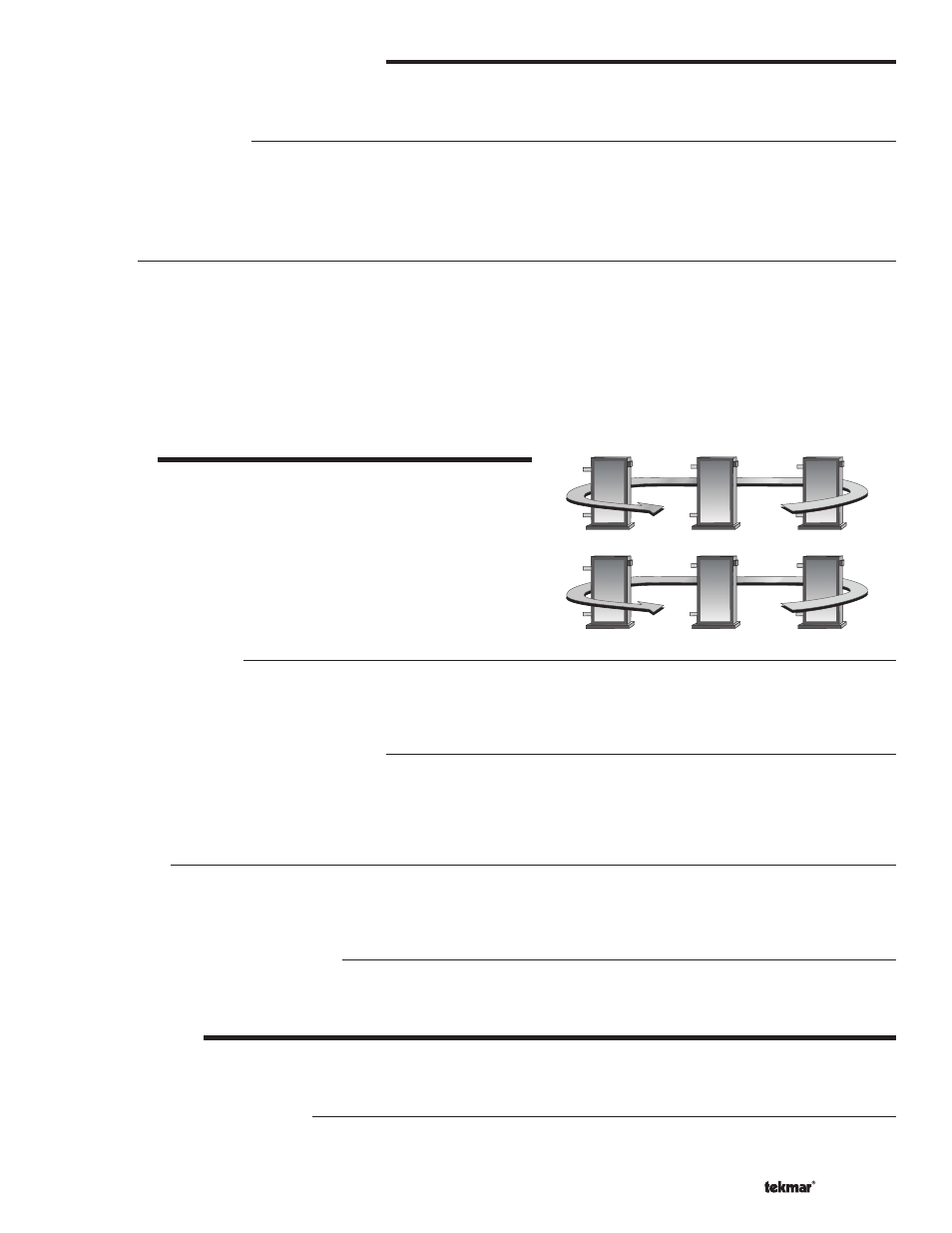

ROTATION

The control’s Equal Run Time Rotation function is fixed at 48 hours. The

firing order of the boilers changes whenever one boiler accumulates 48

hours more running time than any other boiler. After each rotation, the

boiler with the least running hours is the first to fire and the boiler with

the most running hours is the last to fire. This function ensures that all of

the boilers that are being rotated receive equal amounts of use. When

the Rotate / Off DIP switch is set to the Off position, the firing sequence

always begins with lowest boiler to the highest boiler.

Fixed Lead Rotation

In some applications, it may be desirable to have the first boiler fire first at all times while the firing sequence of the remaining

boilers is changed using Equal Run Time Rotation. This rotation option is selected by setting the Fixed Lead / Off DIP switch to

the Fixed Lead position.

First On / Last Off or First On / First Off

When using the Fixed Lead rotation option, a selection must be made between First On / Last Off and First On / First Off

using the DIP switch. When First On / Last Off is selected, the lead boiler is always staged on first and staged off last. When

First On / First Off is selected, the lead boiler is always staged on first and staged off first. This DIP switch is only read by the

control when the Fixed Lead / Off DIP switch is set to Fixed Lead.

Fixed Last

In some applications, it may be desirable to have the last boiler fire last at all times while the firing sequence of the remaining

boilers is changed using Equal Run Time Rotation. This rotation option is selected by setting the Fixed Last / Off DIP switch to

Fixed Last. With a fixed last rotation, the last boiler is the last to stage on and the first to stage off.

Resetting the Rotation Sequence

To reset the rotation sequence, set the Rotate / Off DIP switch to the Off setting for 5 seconds and then return the DIP switch to

the Rotate setting.

RUNNING TIMES

The control displays the accumulated running time of each boiler in the VIEW menu. When using a multi-stage boiler, the running

time that is displayed is the total number of running hours of the Lo stage of the boiler.

Resetting the Running Times

To reset the running time for each boiler, select the appropriate running time in the VIEW menu. Next press the

▲

and

▼

buttons

simultaneously until CLR is displayed.