tekmar 264 Boiler Control User Manual

Page 22

©

2008 D

264

-

12/08

22

of

32

9

Power

L

N

Prim

P1

10 11

L

N

15

14

Relay

1

1

15

14

Relay

1

1

24 to 230 V (ac)

L

N

13

12

C.A./

Alarm

M

24 to 230 V (ac)

L

N

OR

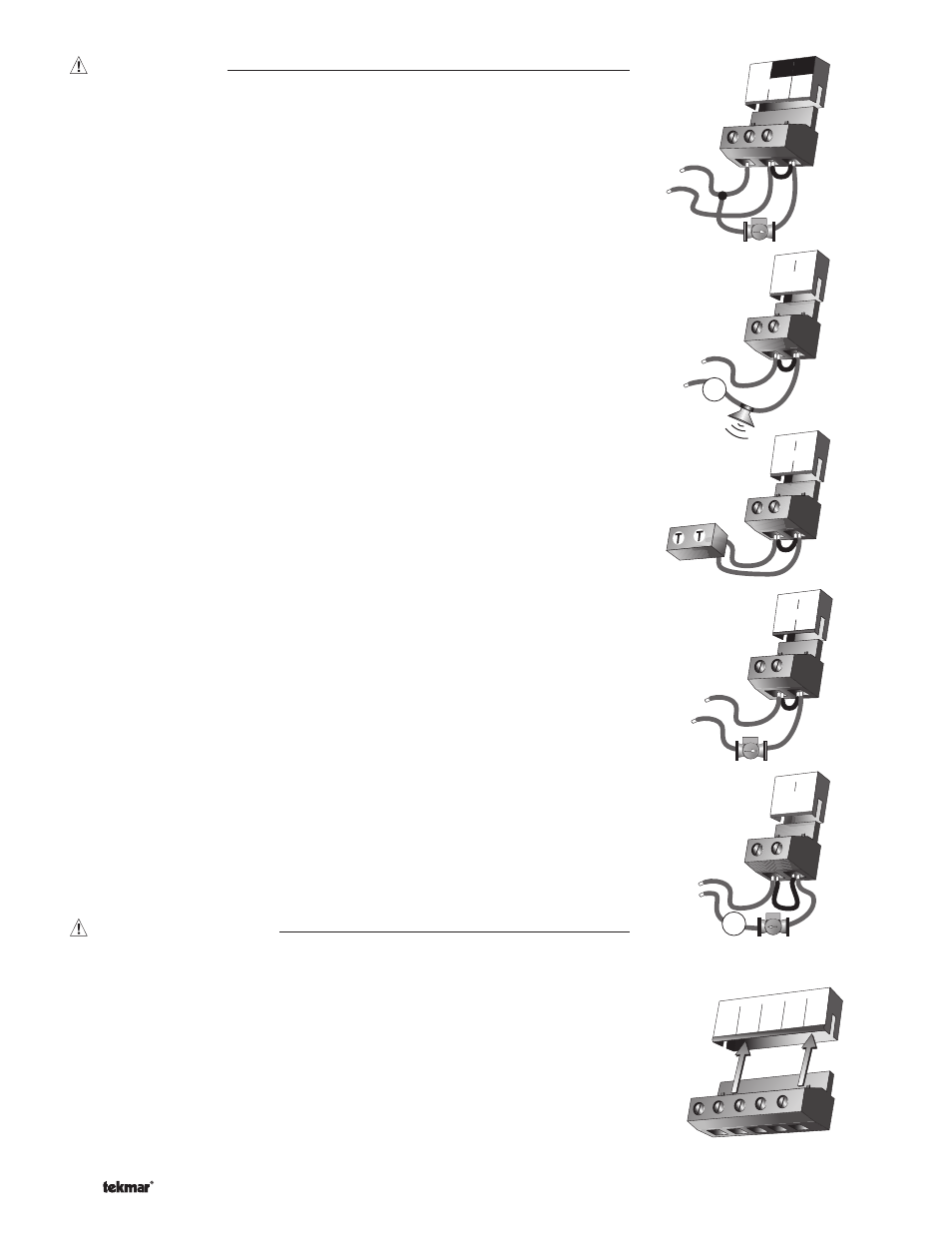

Test The Outputs

Primary Pump

(Prim P1)

If a primary pump is connected to the Prim P1 terminal (11), make sure that power

to the terminal block is off and install a jumper between the Power L and Prim P1

terminals (10 and 11). When power is applied to the Power N and Power L terminals

(9 and 10), the primary pump should start. If the pump does not turn on, check the wiring

between the terminal block and pump and refer to any installation or troubleshooting

information supplied with the pump. If the pump operates properly, disconnect the

power and remove the jumper.

Combustion Air or Alarm

(C.A. / Alarm)

If a combustion air damper or an alarm is connected to the C.A. / Alarm termi-

nals (12 and 13), make sure power to the damper or alarm circuit is off and install a

jumper between terminals (12 and 13). When the circuit is powered up, the combustion

air damper should open or the alarm should activate. If the damper or the alarm fails

to operate, check the wiring between the terminals and the damper or the alarm and

refer to any installation or troubleshooting information supplied with these devices. If

the damper or the alarm operates properly, disconnect the power and remove the

jumper.

Relay 1 to Relay 4

The Relay 1 to Relay 4 terminals (14 and 15 to 20 and 21) are isolated outputs in

the control. There is no power available on these terminals from the control. These

terminals are to be used as a switch to either make or break power to a boiler stage or

a boiler pump. Since this is an isolated contact, it may switch a voltage between 24 V

(ac) and 230 V (ac).

If a boiler pump is connected to the Relay 1 terminals (14 and 15), make sure that

power to the terminal block is off and install a jumper between the terminals. When

power is applied to circuit, the boiler pump should start. If the pump does not turn on,

check the wiring between the terminal block and pump and refer to any installation or

troubleshooting information supplied with the pump. If the pump operates properly,

disconnect the power and remove the jumper.

Repeat the above procedure for Relay 2 to Relay 4.

DHW Pmp / Vlv

If a DHW pump or DHW valve is connected to the DHW Pmp / Vlv contact (22 and 23),

make sure the power to the pump or valve circuit is off and install a jumper between

those terminals. When the DHW circuit is powered up, the DHW pump should turn on

or the DHW valve should open completely. If the DHW pump or valve fails to operate,

check the wiring between the terminals and the pump or valve and refer to any instal-

lation or troubleshooting information supplied with these devices. If the DHW pump or

valve operates correctly, disconnect the power and remove the jumper.

Connecting The Control

Make sure all power to the devices and terminal blocks is off, and remove any remaining

jumpers from the terminals.

Reconnect the terminal blocks to the control by carefully aligning them with their

respective headers on the control, and then pushing the terminal blocks into the headers.

The terminal blocks should snap firmly into place.

Install the supplied safety dividers between the unpowered sensor inputs and the

powered or 115 V (ac) wiring chambers.

Apply power to the control. The operation of the control on power up is described in the

Sequence of Operation section of the brochure.

23

22

DHW

Pmp/Vlv

24 to 230 V (ac)

L

N

M

OR

1 2 3

4

Com

Boil

Ret

Out

5

UnO

Sw

Boil

Sup