E-flite Cessna 150 Aerobat 250 ARF User Manual

Page 21

21

E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

Rudder, Elevator and Nose Gear

Linkage Installation

Required parts

Fuselage assembly Servo hardware

Transmitter

Receiver battery

Nose gear pushrod, 3.31-inch (84mm)

Elevator pushrod, 17.25-inch (438mm)

Rudder pushrod, 18.25-inch (463mm)

Nylon pushrod keeper (2)

Pushrod connector with hardware (2)

Required Tools and Adhesives

Threadlock

Phillips screwdriver: #0, #1

Square

Side cutters

Medium CA

Toothpicks

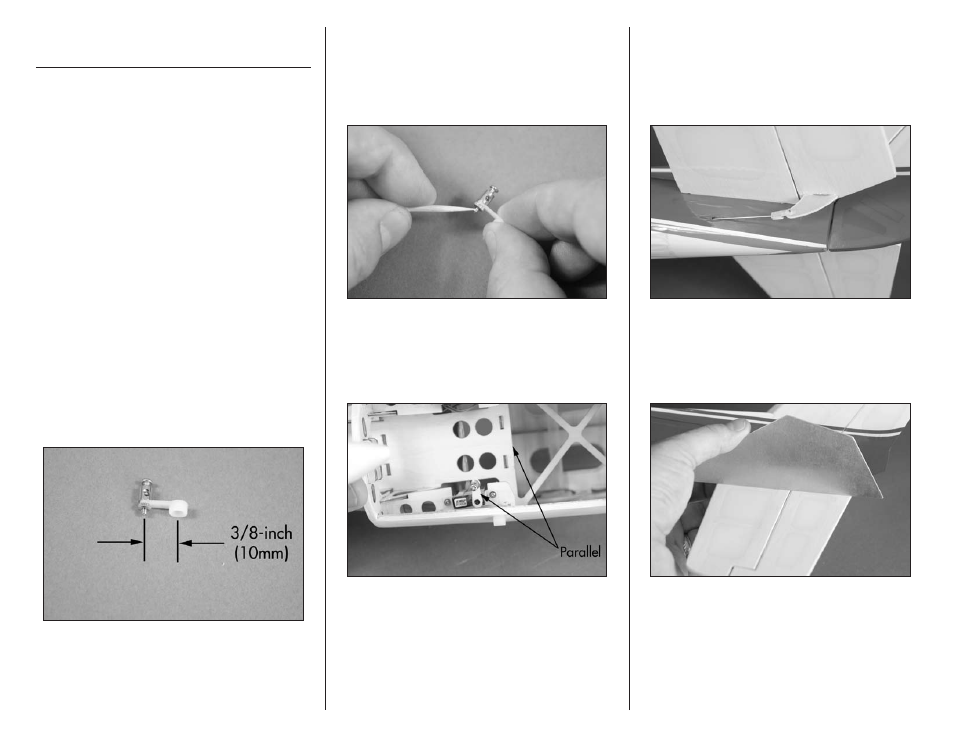

1. Use side cutters to trim one side of the standard

double arm off. Use the other side of the short

double arm for this step. Attach the pushrod

connector to the hole that is 3/8-inch (10mm)

from the center of the servo horn. The washers

that come on the connector are not needed and can

be removed. Tighten the nut so that it is secure

on the arm but is not tight. There should be a

small amount of play between the arm and the

connector and the connector should be able to

rotate freely on the arm.

2. Use a very small amount of medium CA on a

toothpick to secure the nut to the bottom of the

connector threads. Do not use thin CA for this

step as it can wick through the nut and glue the

connector to the arm. Make sure the connector still

rotates freely in the arm after the glue is cured.

3. Center the elevator servo using the transmitter.

Attach the servo horn to the elevator servo using

the screw provided with the servo and a #0 Phillips

screwdriver. The arm will be parallel to the rear

edge of the battery plate in the fuselage.

4. Slide the 17.25-inch (438mm) elevator pushrod

into the tube in the fuselage. Guide the pushrod

wire through the hole in the pushrod keeper that

is attached to the elevator servo horn. Use a

nylon pushrod keeper to secure the pushrod to the

elevator control horn.

5. With the radio system on and the elevator servo

centered, check that the control surface is aligned

with the fixed surface. Use a square between the

two surfaces. Use a #1 Phillips screwdriver to secure

the pushrod in the pushrod connector.