Carbon bracing installation – E-flite 4-Site F3P 250 ARF User Manual

Page 9

9

E-flite 4-Site Assembly Manual

Carbon Bracing Installation

Required Parts

Airframe assembly

12

3

/

4

x 1/32-inch (325mm x 1mm) carbon rod,

Main wing bracing (4)

4

1

/

8

x 1/32-inch (105mm x 1mm) carbon rod,

Outer strut to tip bracing (4)

5

5

/

16

x 1/32-inch (135mm x 1mm) carbon rod,

Top wing to fuselage bracing (2)

5

3

/

4

x 1/32-inch (145mm x 1mm) carbon rod,

Horizontal tail to fuselage bracing (2)

Required Tools and Adhesives

Square

Foam-safe CA

T-pin

When installing the carbon rods, twisting them with

your fingers while inserting them in the hole will help

to smooth the exit and entry of the carbon rod.

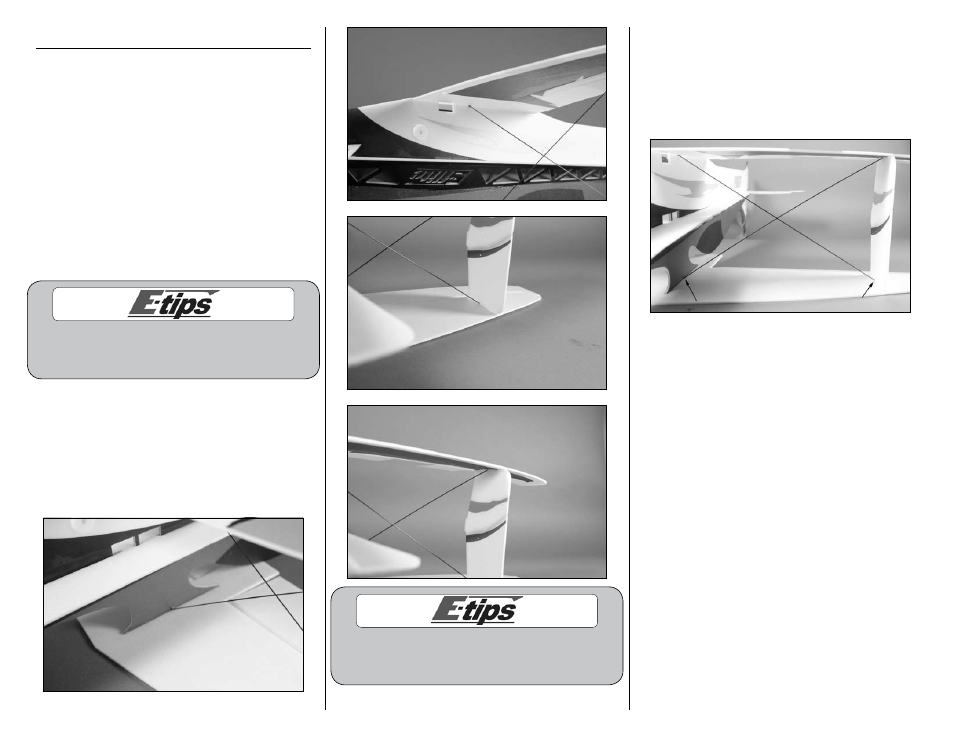

1. Use the following images to position the four

pieces of 12

3

/

4

x 1/32-inch (325mm x 1mm)

carbon rod (two pieces on either side of the

fuselage) that keep the top and bottom wings in

alignment with the fuselage. Do not apply CA until

instructed. The rod that runs from the top of the

center cabane to the lower outer strut should be on

the front of the cross.

When positioning the fuselage upside down on your

work surface, the fin will need to hang off the edge of

your work surface to keep the top wing perfectly flat.

2. With the top wing flat on your work surface,

check that the struts and fuselage are square to the

top and bottom wings. Apply a small amount of

foam-safe CA at the points where the carbon rod

are inserted in the top wing. The rod should be

inserted completely through the wing but should not

protrude past the top of the wing.

3. Make sure to keep the airframe very square

while proceeding. Apply a few drops of foam-safe

CA to the carbon rods where they enter the bottom

wing. Also apply CA to the junction between the

carbon rods where they cross each other. You can

trim off any excess rod from the bottom of the wing

after all four rods have been glued at each joint.