Msm series corner mirrors, Msm series construction, Alignment of sensors and corner mirrors – Banner MSM Series Corner Mirrors User Manual

Page 2

MSM Series Corner Mirrors

page

2

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

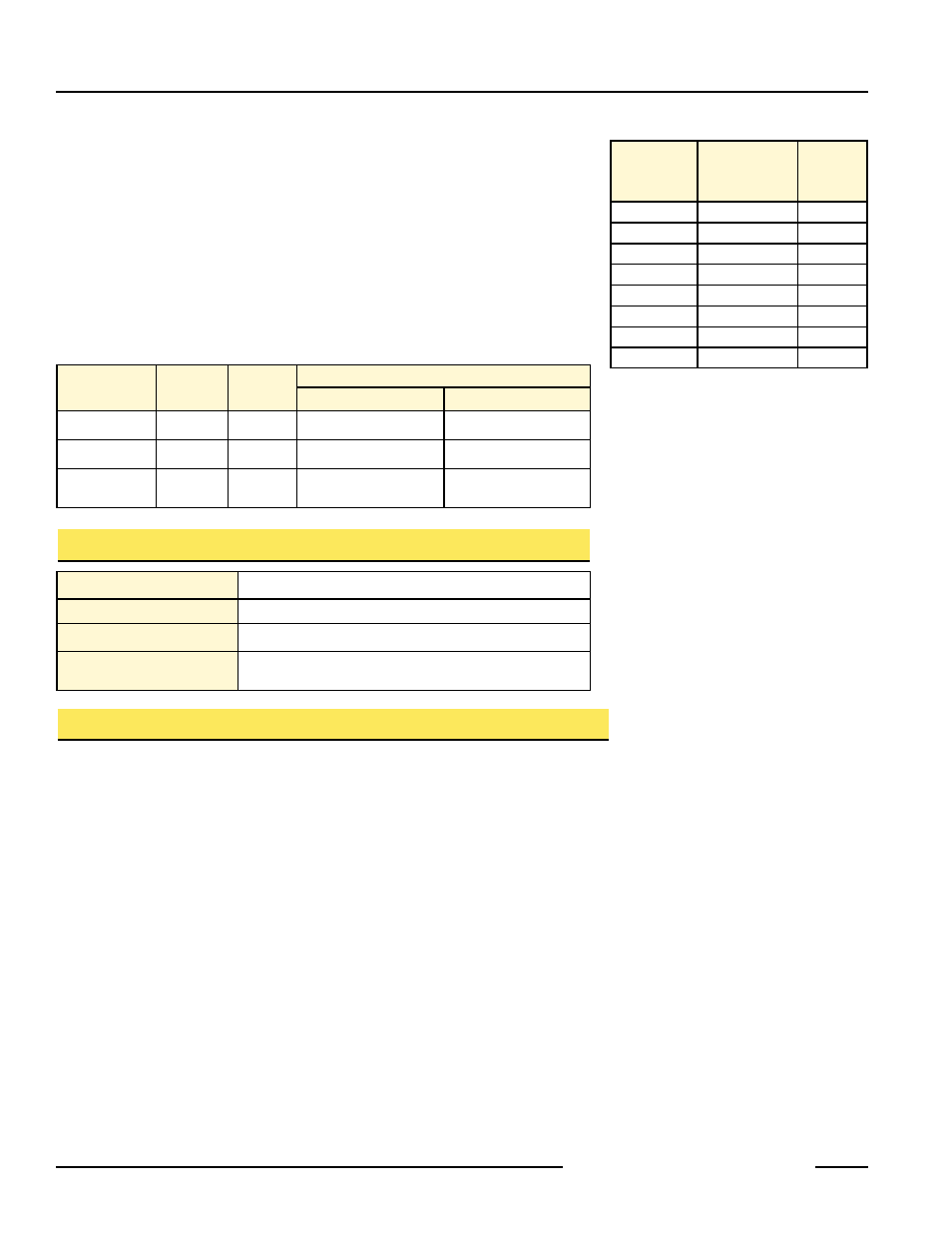

MSM Series mirrors may also be used with light screen sensors up to 48" long. The

table at right, recommends which mirror to use with the applicable sensors.

Each mirror is supplied with two mounting brackets and associated hardware (see

dimension drawing).

Mirrors should be securely mounted to a solid surface that is free from vibration.

Mirrors must be mounted parallel to their sensors, with the midpoint of the mirror(s)

directly in line with the midpoint of the sensor’s defined area.

MSA Series stands may be used to mount MSM Series mirrors. These stands offer an

extruded channel design for convenient mirror (or sensor) height adjustment. See

data sheet P/N 43687 for complete information. Several stand heights are available:

Light Screen

Defined Area

Length Up To

Recommended

Mirror Model

Reflective

Area

Length

8.5"

MSM8A

10.5"

12"

MSM12A

14"

18"

MSM20A

22"

24"

MSM24A

26"

30"

MSM32A

34"

36"

MSM36A

38"

42"

MSM44A

46"

48"

MSM48A

50"

Stand

Model

Part

Number

Stand

Height

Mirror Length

MSA-S24-1

43174

24"

4" to 8"

4" to 12"

MSA-S42-1

43175

42"

4" to 24"

4" to 28"

MSA-S66-1

43176

66"

4" to 48"

4" to 48"

Mirror

Safety glass; rear-surface mirror

Mirror Frame

Molded ABS end caps; rigid PVC sides

Bracket

Cold-rolled steel; black zinc chromate finish

Routine Maintenance

Mirrors should be cleaned with a mild glass cleaning solution

and a soft cloth

MSM Series Construction

Brackets Outward

Brackets Inward

Alignment of Sensors and Corner Mirrors

Mount the mirror(s) and the sensors so that they are all parallel. Use a level, if possible.

Adjust the position of the sensors and the mirror(s) so that the midpoint of the mirror(s)

and the sensors’ defined areas are even. (A line connecting the midpoint of all

components is illustrated by the dashed line in the drawing.) The midpoint of the defined

area of a MICRO-SCREEN sensor is the midpoint of the window. The upper and lower

limits of the defined area of MINI-SCREEN sensors is marked by arrows along the edge

of each sensor window, and is dimensioned in the appropriate instruction manual. The

midpoint of the defined area of MACHINE-GUARD/PERIMETER-GUARD sensors

corresponds to the midpoint of the sensor length.

Adjust the corner mirror(s) so that the angle of incidence to the mirrors equals the angle

of reflection from the mirror. Sight from behind one of the sensors directly towards the

mirror (or the first mirror in line). When alignment is correct, you will see the straight

and centered reflection of the lens of the other sensor in the mirror.

Use the alignment indicator(s) of the safety light screen system (and the appropriate

instruction manual) for final alignment.