Overview, Specifications – Banner SSM Series Corner Mirrors User Manual

Page 2

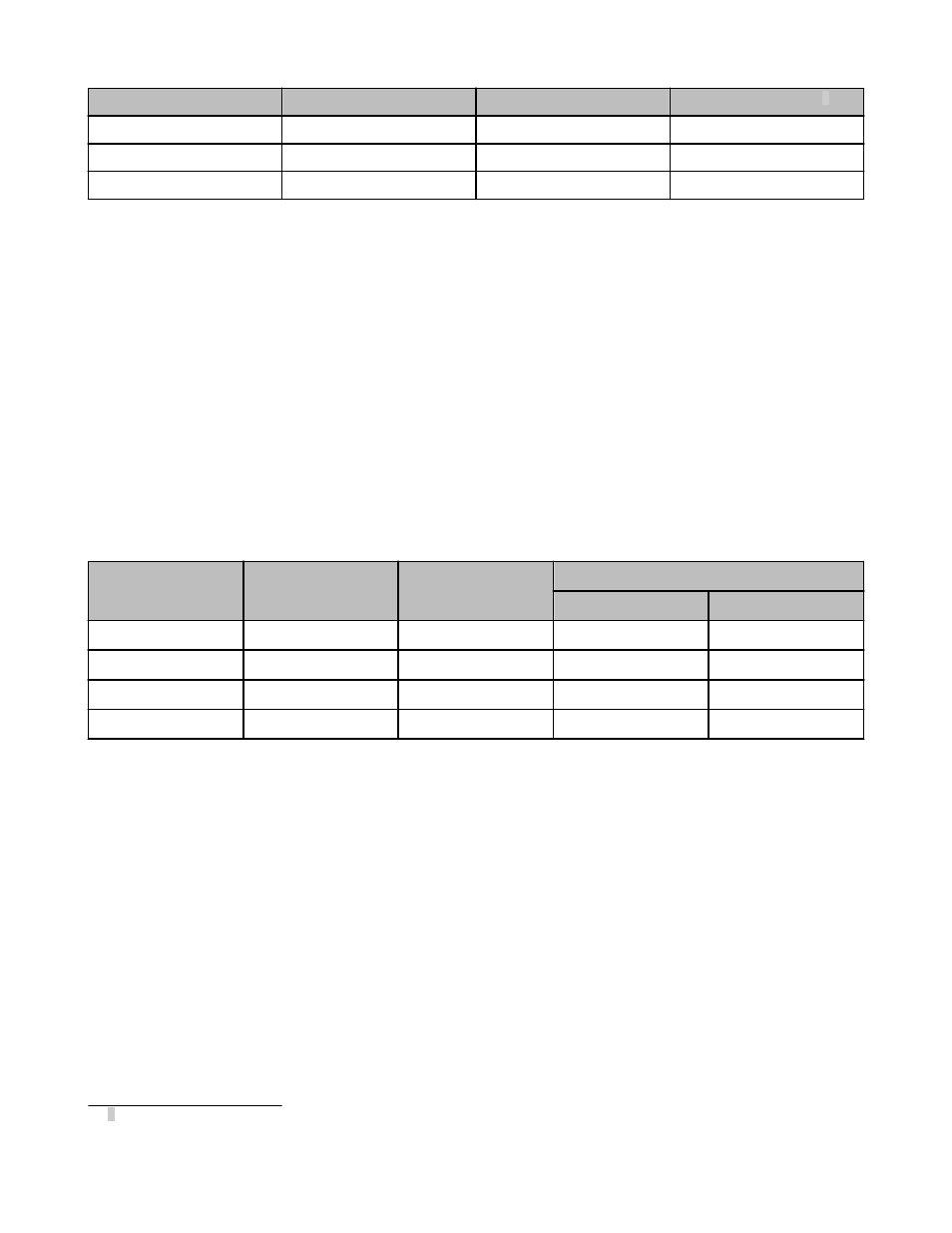

Mirror Model

Reflective Area Height (Y)

Overall Height (L1)

Mounting Height (L2) 1

SSM-1675-S

1675 mm (65.9")

1753 mm (69.0")

1786 mm (70.3")

SSM-1750-S

1750 mm (68.9")

1828 mm (72.0")

1861 mm (73.3")

SSM-1900-S

1900 mm (74.8")

1978 mm (77.9")

2011 mm (79.2")

Overview

Banner SSM-S Series corner mirrors are designed for use with MICRO-SCREEN®, MINI-SCREEN®, and EZ-SCREEN™ Safety Light

Screen systems, and other optical safety systems, including the EZ-SCREEN™ Safety Light Grid and Point. They enable guarding along

more than one side of an area using only one emitter/receiver pair.

SSM-S Series mirrors are compact and extremely robust to withstand industrial environments. Brackets are included for quick and easy

mounting. Once mounted, a unique mirror end cap design allows rotation of the mirror to any angle.

The stainless steel mirrors are rated at 50 percent efficiency. Refer to the information on sensing range and excess gain.

SSM-S Series mirrors are available in 20 lengths. SSM-S Series mirrors may be used with light screen sensors up to 72" long. The table

below recommends which mirror to use with the applicable sensors. The mirror height (Y) should be a minimum of 2" longer than the

distance between the top and bottom beams.

Each mirror is supplied with two mounting brackets and associated hardware. Mirrors should be securely mounted to a solid surface that

is free from vibration. Mirrors must be mounted parallel to their sensors, with the midpoint of the mirror(s) directly in line with the midpoint

of the sensor’s defined area.

MSA Series stands may be used to mount SSM-S Series mirrors (requires adapter kit EZA-MBK-2, P/N 61947, sold separately). These

stands offer an extruded channel design for convenient mirror (or sensor) height adjustment. See datasheet P/N 43687 for complete

information. Several stand heights are available:

Stand Model

Part Number

Stand Height

Mirror Length

Brackets Outward

Brackets Inward

MSA-S24-1

43174

24"

100 mm to 250 mm

100 mm to 375 mm

MSA-S42-1

43175

42"

100 mm to 675 mm

100 mm to 825 mm

MSA-S66-1

43176

66"

100 mm to 1275 mm

100 mm to 1275 mm

MSA-S84-1

52397

84"

100 mm to 1675 mm

100 mm to 1900 mm

Specifications

Construction

Mirror: Highly polished stainless steel

Mirror Frame: Molded PBT end caps; rigid aluminum

extrusion

Bracket: Cold-rolled steel; black zinc chromate finish

Routine Maintenance

Mirror surface will scratch easily. When necessary, mir-

rors should be cleaned with a mild glass cleaning solu-

tion and a soft cloth.

1 The mounting brackets may be inverted from the positions shown at left (flanges pointing “inward” instead of “outward,” as shown). When this is

done, dimension L2 decreases by 58 mm (2.3").

SSM-S Stainless Steel Corner Mirrors

2

www.bannerengineering.com - tel: 763-544-3164

P/N 67200 Rev. C