Control module configuration – Banner A-GAGE High-Resolution MINI-ARRAY Series User Manual

Page 28

P/N 64118 rev. B

Control Module Configuration

28

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

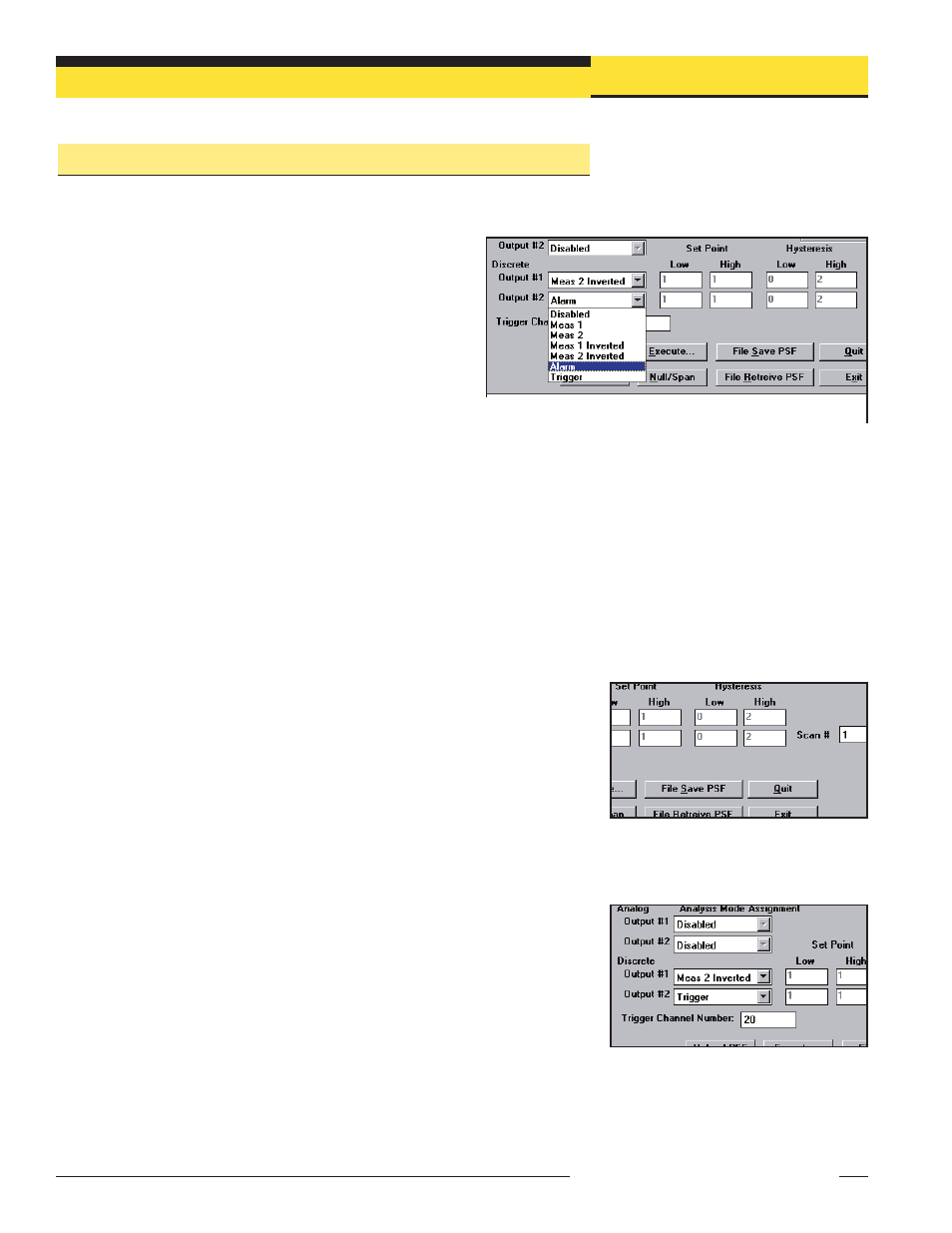

5.3.7 Discrete Output Configuration (Analysis Mode Assignment)

Discrete outputs #1 and #2 (“Alarm”) may each be individually assigned to one of the

Scan Analysis Modes programmed in section 5.3.4 (see Figures 5-16 and 5-22).

Next to each discrete output assignment menu are Low and High

Set Point boxes. The number in each box identifies a beam in the

array (beam #1 being closest to the cabled end of the emitter and

the receiver). The Low and High Set Points may be changed by

clicking on a box and entering a new number.

When the selected Scan Analysis Mode involves first or last beam

blocked or made (unblocked), the assigned output will energize

when the beam identified during a scan falls within the range of

the set points. When the Scan Analysis Mode involves total beams

blocked or made, that assigned output will energize when the

value of total beams counted during a scan falls within the range

of the set points.

Note that the pull-down menus used for assignment of the Scan

Analysis Modes to the discrete outputs include two “Inverted” selections. When either

MEAS1 Inverted or MEAS2 Inverted is selected, that discrete output will de-energize

(turn OFF) whenever a scan analysis value falls within the range of the set points.

Hysteresis values for each end of the set point range may also be set (Figure 5-22).

Hysteresis determines the amount of change that must occur at each set point (High

and Low) to cause the associated output to change state. Hysteresis prevents

unstable output conditions when the scan analysis value exactly matches one of the

set points. The default hysteresis setting is one beam less than the Low Set Point and

one beam more than the High Set Point.

Scan # Provides another way, in addition to hysteresis settings, to smooth output

response. Outputs are updated only after the selected number of identical (within the

hysteresis limits) scans. The menu allows selection of from 1 to 9 scans. For discrete

outputs, the scan analysis value must stay either inside or outside the hysteresis

limits for all of the selected number of consecutive scans, in order for the output to

respond. See Figure 5-23.

Alarm and Trigger

Discrete output #2 (only) has two additional options: Alarm and Trigger.

Alarm: Output #2 energizes whenever the System detects a sensor error (such as a

disconnected cable) or whenever the excess gain of one or more beams becomes

marginal.

Trigger: can be used to gate a second control module when Continuous Scan Method

is also used. When the control module is in straight scanning mode, Trigger Channel

Number defines the beam number during a scan at which the trigger output will occur

(Figure 5-23). The Trigger output is a 100 microsecond (0.0001 sec.) pulse. If the

control module is set for single or double edge scan, the Trigger pulse will come at

the end of the scan (Trigger Channel Number will be ignored).

Figure 5-23. Scan # (PSF Configuration

Screen)

Figure 5-24. Trigger Channel

Figure 5-22. Assigning an Analysis Mode to each Discrete output

(PSF Configuration screen). Alarm and Trigger

output options are available only for Discrete

Output #2.