D.2 multi-drive example, D.2.1 main routine, Slc ladder logic examples – Rockwell Automation MD65 Profibus Communication Card User Manual

Page 93

SLC Ladder Logic Examples

D-7

D.2 Multi-Drive Example

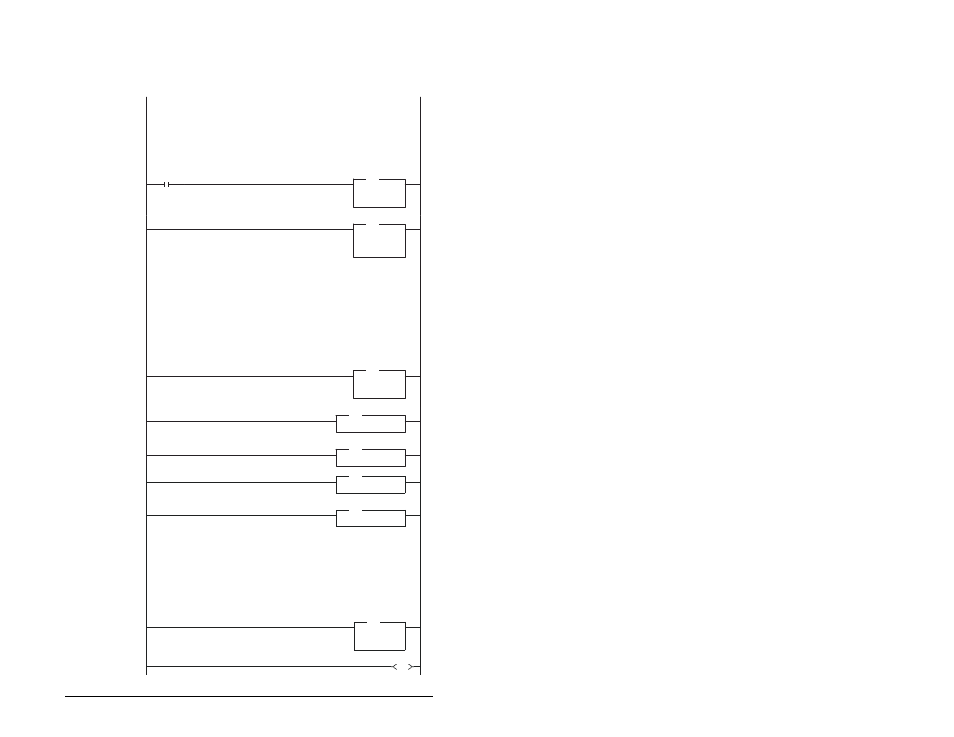

D.2.1 Main Routine

Execute LAD 5 - Station 2 Drive Logic

5

JSR

Jump To Subroutine

SBR File Number

U:5

JSR

Execute LAD 6 - Parameter Protocol

6

JSR

Jump To Subroutine

SBR File Number

U:6

JSR

Write the drives' data to the profibus scanner.

File N20: contains the actual write data generated elsewhere in the ladder program.

Station File No. Description

M0:1.0 (N20:0)

Logic Command Drive 0

M0:1.1 (N20:1)

Speed Reference Drive 0

M0:1.2 (N20:2)

Logic Command Drive 1

M0:1.3 (N20:3)

Speed Reference Drive 1

M0:1.4 (N20:4)

Logic Command Drive 2

M0:1.5 (N20:5)

Speed Reference Drive 2

M0:1.6 (N20:6)

Parameter Access Word 1 (PCA)

M0:1.7 (N20:7)

Parameter Access Word 2 (IND)

M0:1.8 (N20:8)

Parameter Access Word 3 (PVA 1)

M0:1.9 (N20:9)

Parameter Access Word 4 (PVA 2)

7

COP

Copy File

Source

#N20:0

Dest

#M0:1.0

Length

10

COP

8

END

This example program is for a PROFIBUS demonstration using a SLC 5&05 processor with an SST Profibus scanner

(SST-PFB-SLC) in the first slot of the rack. The program is written for 3 drives with one Profibus adapter on the network

(MultiDrive Mode):

Station 0 MD65 with MDCOMM-PBUS

Station 1 MD65

Station 2 MD65

The expample program demonstrates using Logic Command / Reference, Logic Status / Feedback and Parameter

Access using the Parameter Protocol.

On power-up, zero out the transmitt buffer to the Scanner.

0

S:1

15

First Pass

FLL

Fill File

Source

0

Dest

#N20:0

Length

10

FLL

1

MOV

Move

Source

S:3

2561<

Dest

M0:1.4011

?<

MOV

The Scanner is configured to 20 bytes (10 words) of inputs: 4 Bytes "Ctrl/Stat & Ref Fdbk" for each drive (= 12 Bytes)

8 Bytes "Parameter Access"

Read the drives data from the Profibus scanner.

File N10: contains the acutal read data that can be used elsewhere in the ladder program.

Address

Description

M1:1.0 (N10:0) Logic Status Drive 0

M1:1.1 (N10:1) Speed Feedback Drive 0

M1:1.2 (N10:2) Logic Status Drive 1

M1:1.3 (N10:3) Speed Feedback Drive 1

M1:1.4 (N10:4) Logic Status Drive 2

M1:1.5 (N10:5) Speed Feedback Drive 2

M1:1.6 (N10:6) Parameter Access Word 1 (PCA)

M1:1.7 (N10:7) Parameter Access Word 2 (IND)

M1:1.8 (N10:8) Parameter Access Word 3 (PVA 1)

M1:1.9 (N10:9) Parameter Access Word 4 (PVA 2)

2

COP

Copy File

Source

#M1:1.0

Dest

#N10:0

Length

10

COP

Execute LAD 3 - Station 0 Drive Logic

3

JSR

Jump To Subroutine

SBR File Number

U:3

JSR

Execute LAD 4 - Station 1 Drive Logic

4

JSR

Jump To Subroutine

SBR File Number

U:4

JSR

Automatically have the SST-PFB-SCL scanner's watchdog period track that of the

SCL processor (recommended per SST user manual)

Execute LAD 5 - Station 2 Drive Logic

5

JSR

Jump To Subroutine

SBR File Number

U:5

JSR

Execute LAD 6 - Parameter Protocol

6

JSR

Jump To Subroutine

SBR File Number

U:6

JSR

Write the drives' data to the profibus scanner.

File N20: contains the actual write data generated elsewhere in the ladder program.

Station File No. Description

M0:1.0 (N20:0) Logic Command Drive 0

M0:1.1 (N20:1) Speed Reference Drive 0

M0:1.2 (N20:2) Logic Command Drive 1

M0:1.3 (N20:3) Speed Reference Drive 1

M0:1.4 (N20:4) Logic Command Drive 2

M0:1.5 (N20:5) Speed Reference Drive 2

M0:1.6 (N20:6) Parameter Access Word 1 (PCA)

M0:1.7 (N20:7) Parameter Access Word 2 (IND)

M0:1.8 (N20:8) Parameter Access Word 3 (PVA 1)

M0:1.9 (N20:9) Parameter Access Word 4 (PVA 2)

7

COP

Copy File

Source

#N20:0

Dest

#M0:1.0

Length

10

COP

8

END