Slc ladder logic examples – Rockwell Automation MD65 Profibus Communication Card User Manual

Page 91

SLC Ladder Logic Examples

D-5

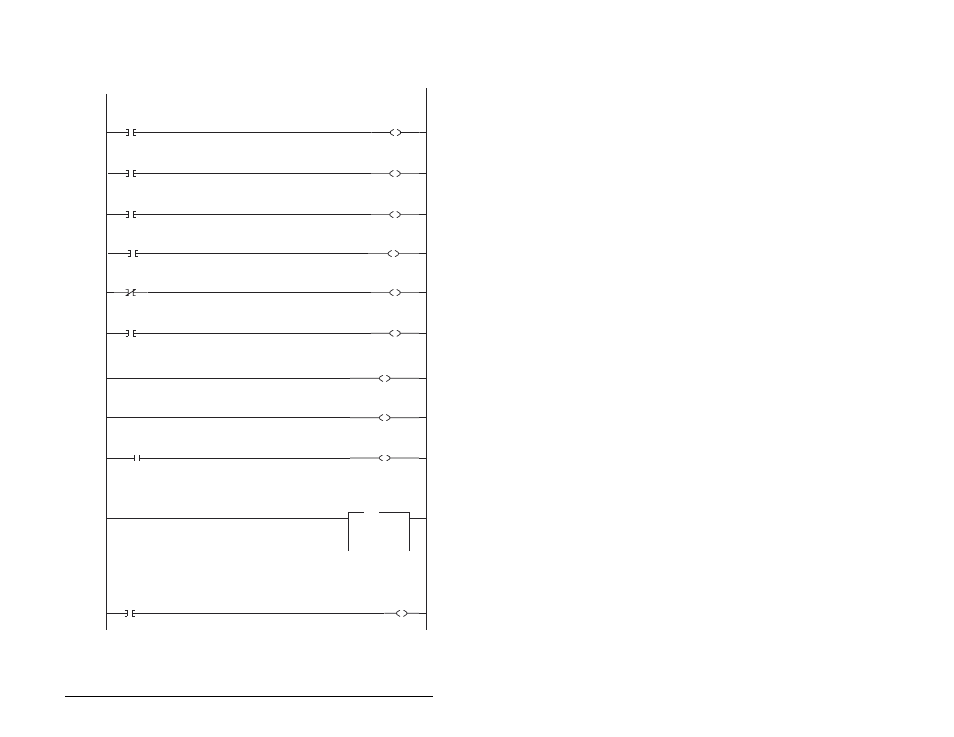

D.1.3 Drive 1 Control/Reference/Parameter Access

Routine

gi

Controlling the Lo c Command word in the drive. B3:21/* bits are controlled elsewhere in the user program.

0

B3:21

0

Station 2

Stop

Command

N20:6

0

Station 2

Logic Command

STOP

1

B3:21

1

Station 2

Start

Command

N20:6

1

Station 2

Logic Command

START

2

B3:21

2

Station 2

Jog

Command

N20:6

2

Station 2

Logic Command

JOG

3

B3:21

3

Station 2

Clear Faults

Command

N20:6

3

Station 2

Logic Command

CLEAR FAULTS

4

B3:21

4

Station 2

Reverse

Command

N20:6

4

Station 2

Logic Command

FORWARD

5

B3:21

4

Station 2

Reverse

Command

N20:6

5

Station 2

Logic Command

REVERSE

To control the speed reference over the Profibus, the three Reference Select bits (bits 14-12) need to have the values 011.

6

N20:6

12

Station 2

Logic Command

REFERENCE SELECT 0

7

N20:6

13

Station 2

Logic Command

REFERENCE SELECT 1

8

B3:21

5

"Never Closed"

N20:6

14

Station 2

Logic Command

REFERENCE SELECT 2

Station 2 Speed Reference

N19:7 is controlled elsewhere in the user program.

9

MOV

Move

Source

N19:7

314<

Dest

N20:7

314<

MOV

Station 2

Speed Reference

Write

This section of the routine is only needed if the application needs to perform Parameter Protocol Reads or Writes to Station 2.

On power-up, initialize the Parameter Protocol routine.

10

S:1

15

First Pass

U

B3:19

0

Station 2

Par Prot

Messaging

Request

The MD65 Speed Reference (parameter 38) needs to be set to 5 ("RS485 [MDI] Port").