Securing a motor control center, Securing methods – Rockwell Automation 2500 CENTERLINE Motor Control Centers Installation Manual User Manual

Page 29

Rockwell Automation Publication 2500-IN001C-EN-P - April 2014

29

Install Columns

Chapter 3

Securing a Motor Control

Center

Documentation packages shipped with assembled MCCs include an MCC

elevation drawing showing an MCC floor plan layout. To secure a column to the

foundation, refer to the provided floor plan layout and the following procedures.

Refer to

for cable and conduit routing instructions.

Securing Methods

MCC columns or shipping blocks can be bolted or welded to a foundation. Two

mounting channels on the bottom of each MCC column are used for either

securing method.

Weld Down Method

for welding a MCC column or shipping block to a

foundation.

Bolt Down Method

The two mounting channels allow up to four steel M12 bolts (minimum

Property Class 8.8) for each MCC column. We recommend that these bolts be

pre-located and embedded in the foundation before installing each MCC

column. See

through

for mounting bolt locations.

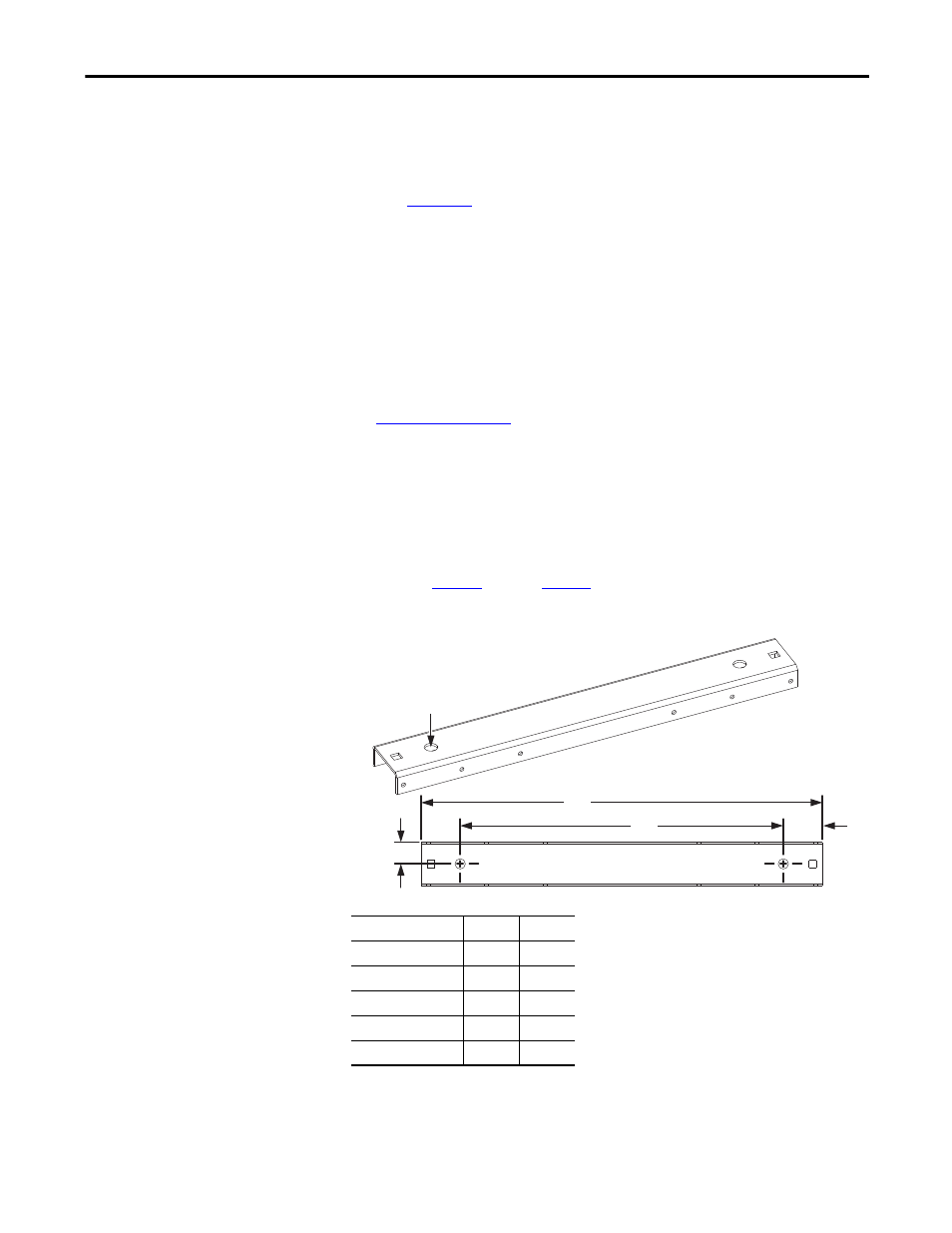

Figure 11 - Mounting Channel Dimensions and Bolt Locations

All dimensions are mm.

MCC Column Width

A

B

600

597

461

700

697

561

800

797

661

900

897

761

1000

997

861

TIP

Mounting channel is not flush with the sides of the MCC column.

A

B

38

68

Mounting holes (2)

18 mm dia.