Power wiring requirements, Motor brake/resistive brake connector, Iam module power wiring requirements – Rockwell Automation 2094-BMxx-M Kinetix 6200 and Kinetix 6500 IAM and AM Power Modules Installation Instructions User Manual

Page 15

Kinetix 6200 and Kinetix 6500 IAM and AM Power Modules 15

Rockwell Automation Publication 2094-IN011D-EN-P - August 2013

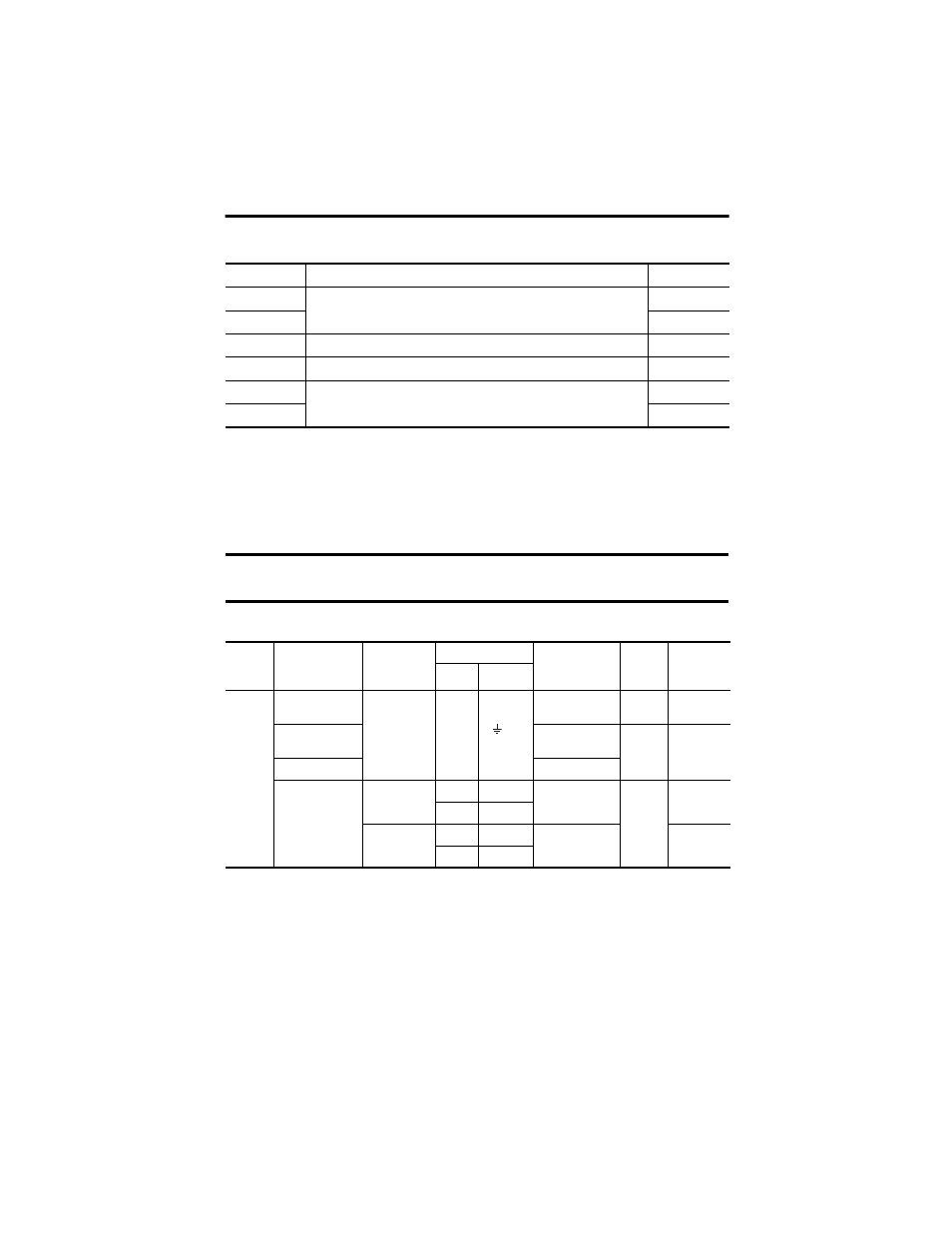

Motor Brake/Resistive Brake Connector

Power Wiring Requirements

Wire must be copper with 75

°C (167 °F) minimum rating. Phasing of main AC power is

arbitrary and earth ground connection is required for safe and proper operation.

IAM Module Power Wiring Requirements

BC Pin

Description

Signal

6

Motor brake connections

MBRK-

5

MBRK+

4

Motor brake common

COM

3

+24V brake input power (from LIM module or customer supplied)

PWR

2

RBM module connections (from RBM module and safety string)

DBRK-

1

DBRK+

IMPORTANT

The National Electrical Code and local electrical codes take precedence over the values and

methods provided.

Module

IAM Module

Cat. No.

Description

Terminals

Recommended

Wire Size

mm

2

(AWG)

Strip

Length

mm (in.)

Torque Value

N•m (lb•in)

Pin

Signal

IAM

(460V)

2094-BC01-M

xx-

M

2094-BC02-M02-

M

DC bus

(1)

and

VAC input power

(1)

Keep DC common-bus connections (leader IAM to follower IAM module) as short as possible.

IPD-1

IPD-2

IPD-3

IPD-4

IPD-5

IPD-6

10…2.5

(8…14)

10

(0.38)

1.2…1.5

(10.6…13.2)

2094-BC04-M03-

M

10…6

(8…10)

16

(0.63)

2.4…3.0

(21.6…26.5)

2094-BC07-M05-

M

30 (3)

2094-BC

xx-Mxx-

M

Control input

power

CPD-1

CTRL 2

4…2.5

(12…14)

10

(0.38)

0.5…0.6

(4.4…5.3)

CPD-2

CTRL 1

Contactor Enable

CED-1

CONT EN-

4…2.5

(12…14)

(2)

(2)

The actual gauge of the contactor enable wiring depends on the system configuration. Consult your machine builder, the NEC, and applicable local

codes.

0.5…0.6

(4.4…5.3)

CED-2

CONT EN+

L3

L2

L1

DC-

DC+